Chemical spills in the workplace represent more than just an inconvenience—they pose significant threats to human health, safety, and the environment. Whether it’s a small-scale incident or a major accident, the consequences of a chemical spill can be far-reaching and potentially catastrophic.

Metro Safety’s expert trainers not only understand the severity of chemical spills but also offer specialized occupational first aid training to workers across heavy-duty industries on how to manage them effectively.

In this blog, we’ll underscore the different types of chemical spills that are common to heavy-duty industries and share ten steps you ought to follow to effectively respond in such a hazardous environment.

Types of Hazardous Chemicals Common to Heavy-Duty Industries

Heavy-duty industries encompass a wide range of sectors, each handling various hazardous chemicals essential to their operations. Understanding the properties and risks associated with these substances is crucial for implementing effective chemical spill response measures.

Here are some common types of hazardous chemicals encountered in heavy-duty industries:

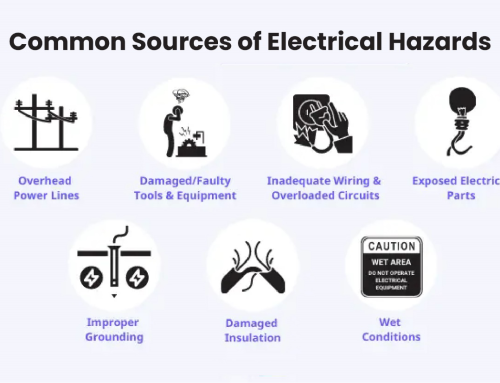

- Corrosive Substances:Heavy-duty industries often deal with corrosive substances such as acids and alkalis. These chemicals have the potential to cause severe burns upon contact with skin or eyes. Examples include sulfuric acid, hydrochloric acid, and sodium hydroxide.

- Flammable Liquids and Gases:Many heavy-duty industries utilize flammable liquids and gases in their processes. These substances are highly combustible and can ignite easily, posing significant fire and explosion hazards. Examples include gasoline, diesel fuel, propane, and hydrogen.

- Reactive Chemicals:Heavy-duty industries may handle reactive chemicals that are unstable and prone to undergoing violent reactions when exposed to air, water, or other substances. Oxidizers, reactive metals, and peroxides are reactive chemicals that require careful handling and storage to prevent accidents.

- Carcinogens and Mutagens:Some heavy-duty industries work with chemicals known to cause cancer (carcinogens) or genetic mutations (mutagens). Exposure to these substances can have long-term health effects and requires stringent safety protocols. Examples include benzene, formaldehyde, and asbestos.

- Asphyxiants: Asphyxiants are gases or vapors that displace oxygen in the air, leading to oxygen deficiency and suffocation. In confined spaces or poorly ventilated areas, the buildup of asphyxiants can pose serious risks to workers. Examples include nitrogen, carbon dioxide, and methane.

10 Steps for Responding to a Chemical Spill

When faced with a chemical spill, prompt and organized action is crucial to mitigate risks and prevent further harm. Here are ten steps for responding to a chemical spill at work:

1. Assess the Situation:

Upon discovering a chemical spill, the first step is to assess the situation thoroughly. This involves evaluating the size, extent, and nature of the spill, as well as identifying the type of chemical involved. Assessing the spill allows responders to determine potential hazards to personnel, property, and the environment. It also helps formulate an appropriate response strategy tailored to the specific characteristics of the spill. Factors such as the location of the spill, weather conditions, and accessibility of the area are also considered during the assessment process.

2. Alert Personnel:

Once the situation has been assessed, it is imperative to alert all personnel in the vicinity of the spill immediately. This includes workers in the affected area, as well as nearby individuals who may be at risk of exposure. Clear and concise communication is essential to ensure that everyone understands the gravity of the situation and follows established safety protocols.

In addition to notifying on-site personnel, it is also important to contact emergency response teams and relevant authorities to provide assistance and coordinate the response efforts effectively.

3. Secure the Area:

After alerting personnel, the next step is to secure the area surrounding the spill to prevent unauthorized access. Establishing a perimeter around the spill site helps minimize the risk of exposure to hazardous chemicals and ensures the safety of workers and bystanders. Physical barriers such as barricades, cones, and tape can be used to cordon off the area and prevent individuals from entering the hazardous zone. Signage and verbal warnings are also employed to communicate the danger and deter people from approaching the spill site without proper authorization or protective equipment.

4. Don Personal Protective Equipment (PPE):

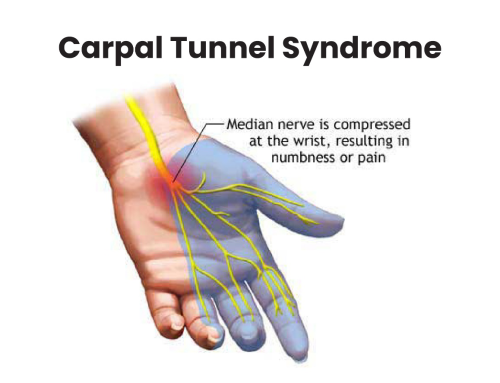

Before responding to a chemical spill, personnel must don appropriate personal protective equipment (PPE) to minimize the risk of exposure and injury. The type of PPE required depends on the nature of the spilled chemical and the potential hazards involved. Common types of PPE include chemical-resistant gloves, safety goggles or face shields, protective clothing, and respiratory protection. Ensuring that responders are properly equipped with the necessary PPE is essential for their safety and well-being during spill response activities.

5. Contain the Spill:

Containing the spill is critical to prevent the further spread of the hazardous substance and minimize its impact on the surrounding environment. Spill containment involves deploying absorbent materials such as spill pads, pillows, or booms to confine the spilled chemical and prevent it from spreading to adjacent areas. Dikes or barriers may also be used to contain liquids and prevent runoff into drains or waterways. Responders can limit the spill’s potential to cause harm by promptly containing it and facilitating more effective cleanup and remediation efforts.

6. Control the Source:

Once the spill has been contained, efforts are focused on controlling the source of the release to prevent additional chemicals from entering the environment. Identifying the source of the spill is crucial for implementing effective control measures and stopping the release of hazardous substances. This may involve shutting off valves, plugs, or containers to contain the leak and minimize further environmental contamination. By controlling the source of the spill, responders can mitigate its impact and reduce the risk of harm to human health and the environment.

7. Initiate Cleanup Procedures:

7. Initiate Cleanup Procedures:

With the spill contained and the source controlled, responders can proceed to initiate cleanup procedures to remove the spilled chemical and mitigate its environmental impact. Cleanup efforts typically involve following established spill response protocols and procedures outlined in the company’s spill response plan.

This may include using appropriate spill cleanup kits and absorbents to safely manage and neutralize the spilled chemical, as well as employing specialized equipment and techniques to address specific cleanup challenges. By initiating cleanup procedures promptly, responders can minimize the duration and extent of environmental contamination and facilitate the restoration of affected areas.

8. Dispose of Contaminated Materials:

Proper disposal of contaminated materials is essential to prevent further environmental contamination and ensure compliance with regulatory requirements. Once cleanup activities are complete, responders must collect and properly dispose of contaminated materials, including absorbents, personal protective equipment (PPE), and any residual chemicals. This may involve segregating hazardous waste from non-hazardous waste, packaging it securely, and arranging for its safe transportation and disposal by authorized waste management providers.

9. Decontaminate Personnel and Equipment:

After cleanup activities, thorough decontamination of personnel, equipment, and affected areas is essential to minimize the risk of secondary exposure and ensure responder safety. Decontamination procedures may involve washing affected skin areas with soap and water, flushing eyes with clean water, and removing contaminated clothing and PPE. Equipment and tools used during spill response activities should also be decontaminated using appropriate cleaning agents and methods to remove residual chemicals effectively.

10. Document the Incident:

Documenting the incident is crucial for post-incident analysis, regulatory reporting, and future prevention efforts. Responders should keep detailed records of the spill incident, including the nature and extent of the spill, response actions taken, personnel involved, and any environmental impacts or property damage incurred. This information helps organizations assess the effectiveness of their spill response procedures, identify areas for improvement, and implement corrective measures to prevent similar incidents in the future.

Relevance of Metro Safety’s Occupational First Aid Courses

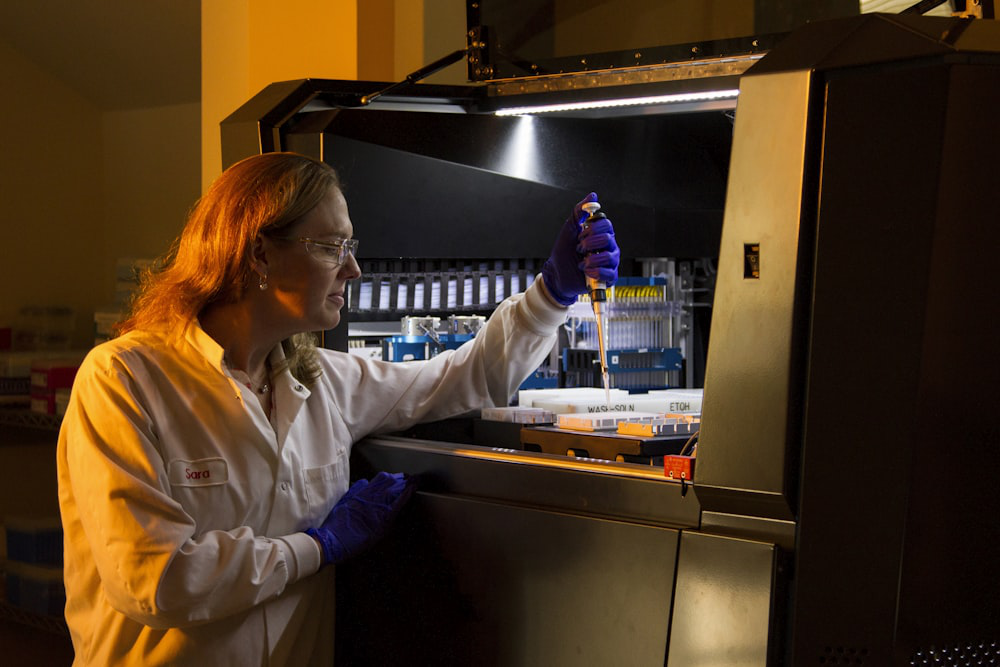

In the event of a chemical spill or other workplace emergency, having personnel trained in occupational first aid is invaluable. Metro Safety offers comprehensive Occupational First Aid Courses designed to equip individuals with the knowledge and skills to respond effectively to medical emergencies, including those involving chemical exposure or contamination.

Our OFA courses cover a range of topics, including wound care, CPR, AED usage, and emergency response protocols. Participants learn how to recognize and assess medical emergencies, administer appropriate first-aid treatments, and coordinate with emergency medical services when necessary.

In the context of a chemical spill, trained first aid responders play a critical role in providing immediate assistance to individuals affected by chemical exposure or injuries. They can assess the severity of injuries, administer appropriate first-aid interventions, and facilitate the safe evacuation and treatment of affected individuals.

Enroll your team in Metro Safety’s Occupational First Aid Courses today! Equip your personnel with the knowledge and skills to effectively respond to chemical spills and other workplace emergencies. To learn more about our offerings, visit our website.