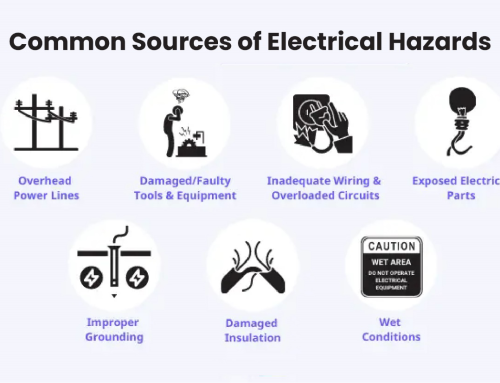

Industrial workplaces are fraught with various risks, from electrical hazards to fires, slips, and chemical exposure to name a few. One major cause of many accidents across industrial workplaces is the handling of hazardous materials. Therefore, safeguarding against the potential risks of these materials is not just a legal requirement but an ethical responsibility to ensure a secure and healthy working environment.

That’s why this guide will explore various types of hazardous materials that industrial workers confront daily and shed light on how Metro Safety’s Occupational First Aid (OFA) training courses are instrumental in fostering expertise and responsibility in hazardous materials safety.

Types of Hazardous Material

1. Chemical Agents

Industrial workers often contend with the risks posed by chemical agents, where inhalation dangers, skin irritation, and long-term health implications loom large. To mitigate these risks, strict adherence to proper ventilation practices, mandatory use of personal protective equipment (PPE), and a meticulous commitment to storage guidelines are paramount.

2. Biological Hazards

Within industrial environments, the spectrum of biological hazards brings forth multifaceted threats, ranging from infections and allergies to respiratory issues. That’s why being immunized, using PPE at all times, and containment protocols must all be followed to ensure everyone’s safety. In essence, confronting biological hazards demands a comprehensive strategy, encompassing preventive measures, protective gear utilization, and strict adherence to containment protocols.

3. Radioactive Substances

Industrial landscapes dealing with radioactive substances demand an elevated level of awareness owing to the severe health risks posed by radiation sickness and cancer. Addressing radioactive substances requires not only technical expertise but an unwavering commitment to safety protocols. For example, the use of shielding becomes paramount, ensuring that workers are adequately protected from radiation exposure as well as continuous monitoring of radiation levels, setting up safety-zones, etc.

4. Flammable Materials

The presence of flammable materials in industrial settings introduces a critical dimension of risk, primarily associated with the potential for fires and explosions. Mitigating these risks requires a multifaceted approach. Regular emergency response drills, using fire-resistant containers, and controlled storage practicescan ensure that industrial workers are well-versed in the swift and effective execution of emergency shutdown procedures.

5. Corrosive Substances

Corrosive substances pose substantial risks, including burns and tissue damage, making their safe handling imperative within industrial settings. Workers dealing with corrosive materials must be equipped with proper handling gearto minimize direct contact and potential harm. Should there be contact, decontamination and emergency protocols must be followed to ensure worker safety.

Regulations for Industrial Workers: Ensuring Safety and Compliance

WorkSafe BC, as the regulatory authority overseeing workplace safety in British Columbia, plays a pivotal role in establishing and enforcing regulations to safeguard industrial workers. The authority mandates comprehensive training programs to ensure that industrial workers are well-versed in the safe handling, storage, and disposal of hazardous materials. This includes rigorous protocols for risk assessments, emergency response, and proper utilization of Personal Protective Equipment (PPE).

Additionally, WorkSafe BC outlines explicit requirements for workplace safety practices. This encompasses protocols for the maintenance and inspection of equipment, the implementation of emergency response plans, and the provision of ongoing training to keep workers abreast of the latest safety procedures.

Occupational First Aid Training for Industrial Workers

Metro Safety’s Occupational First Aid (OFA) courses are meticulously crafted to empower industrial workers with the skills and knowledge necessary for the safe handling of hazardous materials.These courses are not mere certifications; they are immersive experiences designed to cultivate an expert understanding of hazardous materials safety. Our courses are also compliant with WorkSafe BC regulations, making them a vital resource for learning workplace safety practices.

Participants engage in critical learnings that extend beyond regulatory compliance, fostering a proactive safety culture within industrial settings. From mastering risk assessment techniques to understanding legal and ethical considerations, our OFA courses equip workers with a comprehensive skill set.

Here’s a closer look at what you can expect to learn:

1. Risk Assessment Techniques

Participants undergo intensive training in identifying and assessing potential risks associated with specific hazardous materials in their workplace. This goes beyond routine hazard recognition, equipping workers with the skills to conduct thorough risk assessments. The objective is to cultivate a proactive approach where potential dangers are preemptively recognized and addressed.

2. Proper Use of Personal Protective Equipment (PPE)

Within the context of hazardous materials safety, the program places a significant emphasis on the correct and effective use of Personal Protective Equipment (PPE). Workers not only learn about the diverse types of PPE available but also understand the nuanced selection and application of the right gear for specific hazardous materials. This ensures not just compliance but a comprehensive understanding of minimizing the risk of exposure.

3. Emergency Response Protocols

A critical component of the OFA training involves preparing workers to respond swiftly and effectively in the event of a hazardous material incident. This includes comprehensive training in emergency response protocols, ensuring that participants can navigate high-pressure situations with a level-headed approach. The goal is to minimize the impact of the incident and ensure the safety of all personnel involved.

4. Handling and Storage Procedures

Detailed instruction is provided on the intricacies of storing and transporting hazardous materials. This involves understanding the unique requirements of different materials, ensuring optimal storage conditions, and minimizing the risk of incidents such as spills or leaks during handling and transportation. Participants gain insights into best practices that align with safety regulations.

5. Decontamination Processes

A crucial aspect of hazardous materials safety is post-handling decontamination. Participants are trained on thorough decontamination procedures, preventing cross-contamination and ensuring a safe transition to subsequent tasks. This meticulous decontamination process is integral to maintaining a safe working environment and preventing residual hazards.

6. Recognition of Hazardous Materials Labels

A key skill imparted in the program is the ability to interpret and understand labels on hazardous materials. Participants become adept at comprehending the information provided on labels, recognizing potential risks, and taking appropriate precautions based on the indicated hazards. This skill is pivotal for safe decision-making during the handling and storage of hazardous materials.

7. Emergency Shutdown Procedures

In the event of a hazardous material emergency, participants are trained to execute prompt and effective shutdown procedures. This involves a coordinated cessation of operations to contain the incident and prevent its escalation. Such emergency shutdown procedures are critical for minimizing the scope of the incident and ensuring the safety of all personnel within the industrial setting.

8. Legal and Ethical Considerations

The program delves beyond the technical aspects, providing a comprehensive exploration of the legal and ethical dimensions of handling hazardous materials. Participants are educated on the specific legal responsibilities associated with the handling, storage, and disposal of hazardous materials. The emphasis is on fostering an ethical and compliant approach, ensuring accountability and adherence to regulatory standards.

Prioritize Your Safety: Enrol Now!

By delving deep into risk assessments, emergency response protocols, and ethical considerations, our courses go beyond compliance, fostering a culture of vigilance and accountability. Your journey to a safer workplace begins with knowledge, and Metro Safety is your guide.

Our Occupational First Aid courses come in three levels of expertise, and we also offer various workplace-specific courses on confined space safety, fall protection, and forklift operation.

Visit our website to learn more about hazardous materials safety!