Electricity is an invisible force that powers our lives, but it can also be a serious safety hazard in the workplace. Every year, thousands of workplace accidents involve electricity, resulting in injuries, burns, and even fatalities.

For those working with electrical equipment or in environments where electricity is present, understanding electrical safety protocols is crucial. This blog will delve into the major hazards of electrical work, and provide best practices for electricians and other professionals to ensure a safe and healthy work environment.

Major Hazards in Electrical Work

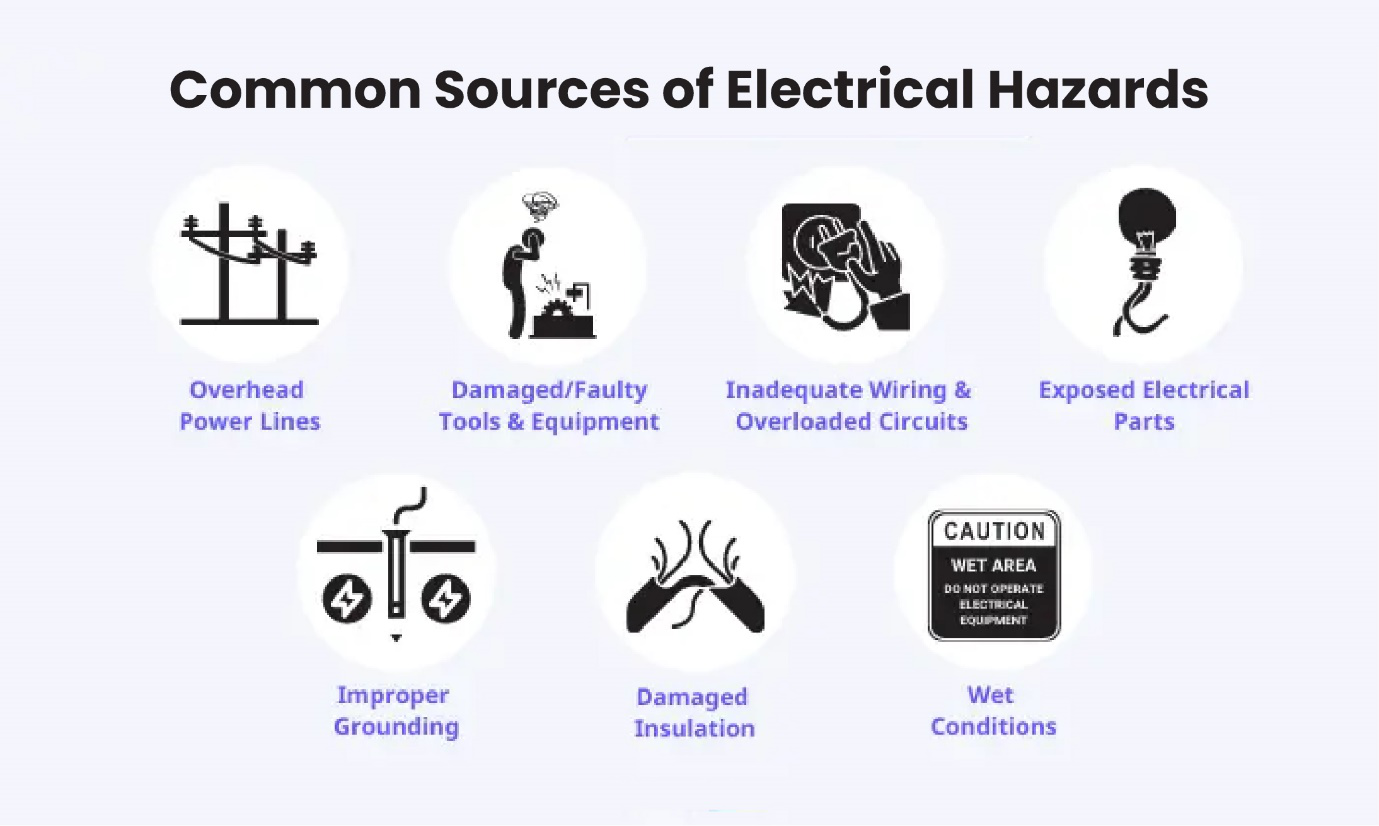

Working with electricity comes with inherent risks. Here’s a breakdown of some of the most significant hazards:

- Electric Shock:This occurs when electrical current passes through the human body. It can cause a wide range of effects, from mild tingling to involuntary muscle contractions (tetany) to cardiac arrest and respiratory failure. The severity of the shock depends on factors like the amount of current, the path it takes through the body, and the duration of exposure.

- Electrocution:The most severe consequence of electrical shock is electrocution, which refers to death caused by electrical current. It can be immediate or occur hours later due to internal injuries.

- Arc Flash:This is a sudden explosion of intense heat and light caused by a high-current electrical discharge through air. This extreme heat can cause third-degree burns within milliseconds of exposure, even through clothing. Arc flashes also generate a powerful shockwave that can propel objects and debris at high speeds.

- Arc Blast:The intense pressure wave generated by an arc flash can propel objects and debris at speeds exceeding 100 miles per hour, with forces strong enough to crush concrete walls. This flying debris can cause blunt force trauma, broken bones, and severe penetrating injuries.

- Electrical Fires:Faulty wiring, overloaded circuits, and improper use of electrical equipment can all lead to electrical fires, which can quickly engulf a workspace and pose a significant threat to life and property.

- Ground Faults:This occurs when a hot (live) wire comes into contact with a grounded surface, such as a metal conduit or the ground itself. Ground faults can create a path for current to flow through a person who comes into contact with the grounded object.

In addition to these immediate dangers, long-term exposure to electrical fields can also have health consequences. While the research on this is ongoing, some studies suggest a potential link between prolonged exposure to certain electrical fields and an increased risk of certain cancers.

The risk factors associated with electrical hazards can vary depending on the specific job and work environment. However, some common factors include:

- Working with high-voltage electricity (generally considered anything above 50 volts)

- Working in wet or damp environments

- Using damaged or defective electrical equipment

- Lack of proper training or knowledge about electrical safetyprocedures

- Ignoring safety protocols or using unsafe work practices

Best Practices to Ensure Electrical Safety

By adopting safe work practices and implementing essential safety measures, electrical hazards can be significantly reduced. Here are 10 best practices every electrician and other professionals working around electricity should follow:

1. Prioritize Training and Knowledge:

Adequate training is the cornerstone of electrical safety. Electricians should possess a relevant electrical trade qualification that equips them with the knowledge and skills to work safely with electrical systems. This training should cover topics such as electrical theory, safe work practices, hazard identification, proper use of electrical equipment, and emergency procedures. However, electrical safety education shouldn’t be limited to electricians. For non-electricians who work in environments with electrical hazards, even basic electrical safety training can make a significant difference. Understanding basic electrical principles and how to identify potential dangers empowers these workers to take necessary precautions and avoid putting themselves at risk.

2. Perform Pre-Job Risk Assessments:

Before starting any electrical work, a thorough risk assessment is crucial. This proactive approach helps identify potential hazards specific to the job at hand. A comprehensive assessment should consider factors such as the type of work being performed (e.g., installation, maintenance, repair), the voltage involved (higher voltage poses greater risk), the work environment (wet or damp conditions increase conductivity), and the personal protective equipment (PPE) required to mitigate identified risks. By conducting a pre-job risk assessment and addressing any potential hazards before work begins, electricians and other workers can significantly reduce the risk of electrical accidents.

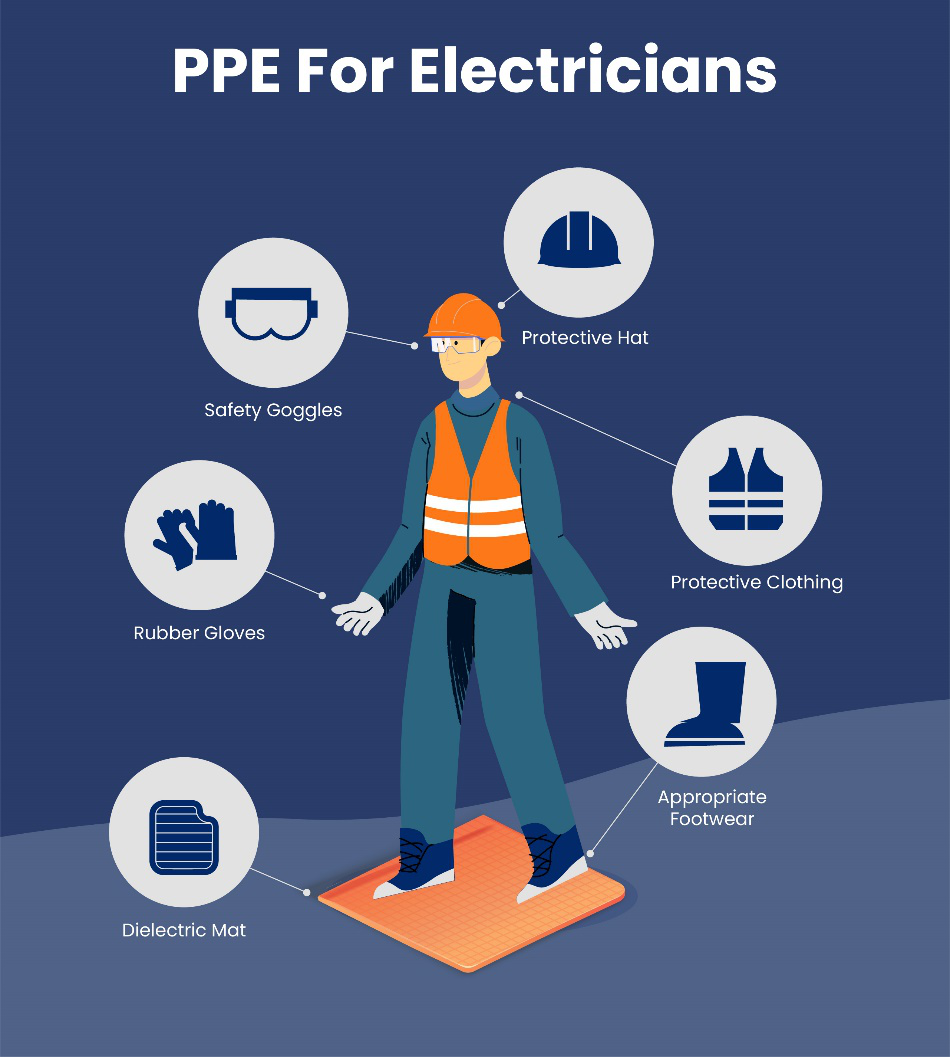

3. Utilize Proper Personal Protective Equipment (PPE):

Personal protective equipment (PPE) plays a critical role in safeguarding workers from electrical hazards. The specific type of PPE required will vary depending on the job and the voltage involved. However, some essential PPE for electrical work includes:

- Insulated Gloves:These gloves provide a barrier against electrical current and are rated for specific voltage levels. Choosing the appropriate glove rating for the job ensures optimal protection.

- Insulated Footwear:Electrical shock can travel through the body via the ground. Insulated footwear protects workers against this path of current flow in case of a ground fault.

- Safety Glasses:Electrical work can involve flying debris from potential arc flashes, which can cause severe eye damage. Safety glasses with side shields offer essential protection for the eyes.

- Flame-Resistant Clothing:Arc flashes generate intense heat that can cause severe burns. Flame-resistant clothing helps protect workers against thermal injuries during arc flash incidents.

- Face Shield:For tasks with a high risk of arc flashes, a face shield offers additional protection for the face and neck from intense heat and light.

By utilizing the appropriate PPE and ensuring it’s properly maintained and in good condition, workers significantly reduce the risk of injuries from electrical hazards.

4. De-Energize Equipment Before Working On It:

Whenever possible, electrical equipment should be de-energized (shut off and locked out) before any work is performed. This critical safety measure involves following a safe lockout/tagout procedure to ensure the equipment cannot be accidentally re-energized while work is underway. Lockout/tagout procedures typically involve physically locking out electrical disconnect switches and placing warning tags on the equipment to indicate that it is not to be operated. Only qualified electricians should be responsible for both de-energizing and re-energizing electrical equipment. Following a safe lockout/tagout procedure is an essential step in preventing electrical shock and ensuring worker safety.

5. Test Before You Touch:

Even after de-energizing equipment, it’s essential to verify that all electrical conductors are truly de-energized before making physical contact. This verification process involves using a reliable voltage tester to measure the voltage on the conductors. Only qualified electricians should perform voltage testing, and they should use appropriate testing equipment rated for the voltage level of the system being worked on. By testing before touching, electricians can ensure that all potential sources of electrical energy have been removed before proceeding with work, further minimizing the risk of electrical shock.

6. Use Grounding and Bonding Practices:

Proper grounding and bonding are essential safety measures that help prevent electrical shock and equipment damage. Grounding provides a low-resistance path for unwanted current to flow safely to the earth. Bonding electrically connects conductive objects together to equalize their potential and minimize the risk of voltage differences that could cause shock. Electricians should ensure that all electrical systems are properly grounded and bonded according to relevant electrical codes and safety standards.

7. Maintain a Clean and Dry Work Environment:

Water and moisture can significantly increase the risk of electrical shock. A wet environment can conduct electricity more readily, creating a greater potential for current to flow through a worker’s body. Therefore, it’s crucial to maintain a clean and dry work area whenever possible. If working in a damp or wet environment is unavoidable, extra precautions should be taken, such as using GFCI (ground fault circuit interrupter) outlets and ensuring all electrical equipment is properly sealed and rated for use in such conditions.

8. Utilize Ground Fault Circuit Interrupters (GFCIs):

GFCIs are life-saving devices that can significantly reduce the risk of electrical shock. They continuously monitor the electrical current flowing through a circuit and are designed to interrupt the circuit if they detect a ground fault – a situation where current leaks to the ground instead of completing the circuit path. GFCIs are particularly important in areas with a higher risk of moisture, such as bathrooms, kitchens, and outdoor workspaces. By utilizing GFCIs and ensuring they are regularly tested, workers can add an extra layer of protection against electrical shock hazards.

Prioritize Electrical SafetyWith Metro Safety’s Occupational First Aid Training!

Remember, electrical safety is a shared responsibility. Employers have a duty to provide a safe work environment and ensure workers have the necessary training and equipment. Workers, in turn, have a responsibility to follow safe work practices and use PPE as directed.

As a leading training center operating out of Coquitlam, BC, Metro Safety has been providing top-notch occupational first aid and workplace safety trainings to residents of British Columbia since 2008. These trainings are geared towards a number of niches within heavy duty industries, including electricians, and explore various techniques to tackle burns, sprains, even unconscious personnel.

In addition, we also offer courses on confined space safety, fall protection and inspection, as well as emergency first aid courses designed in collaboration with the Canadian Red Cross. Explore our course offerings to improve electrical safety at your workplace! Visit our website today to enroll.