Working in silos demands a unique set of skills and precautions to ensure the safety of individuals entering or working in these confined spaces. Silos, prevalent in various industries, including construction, agriculture, and manufacturing, present specific challenges that necessitate specialized training.

Here at Metro Safety Training, we address these challenges and then some through our Confined Space Safety Courses designed both for monitor and entrant as well as standby persons, equipping workers with essential skills to navigate confined space safety in silos.

Risks in Silo Work: Navigating the Complexities

Working in silos presents a unique set of challenges and potential hazards for employees. Understanding these risks is crucial for prioritizing confined space safety. Here are several risks that silo workers routinely face:

1. Fall Hazards

Silo structures, often towering several stories high, pose a significant risk of falls for workers. Unprotected edges, deteriorating platforms, and a lack of guardrails contribute to the potential for severe injuries. Climbing ladders or navigating narrow walkways within the silo increases the likelihood of accidents. Workers may also encounter uneven surfaces or trip hazards, amplifying the risk of falls. Given the height and confined spaces, any fall incident can result in grave injuries or fatalities.

2. Engulfment

Handling bulk materials like grains, pellets, or liquids in silos introduces the peril of engulfment. During loading or unloading processes, the risk of being buried or immersed in flowing materials is substantial. This scenario could lead to suffocation and requires swift and well-coordinated rescue efforts to prevent fatalities. The force exerted by the materials can be immense, making it challenging to extricate a worker once engulfed.

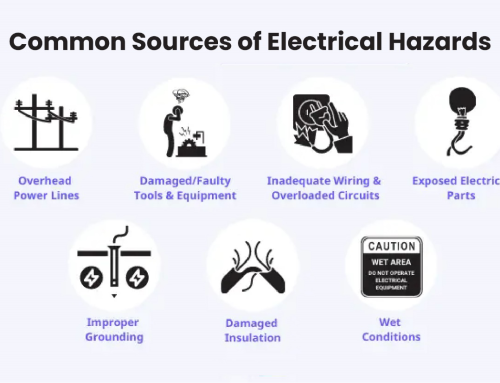

3. Toxic Atmospheres

Certain stored materials within silos can emit harmful gases or vapors. Workers may unknowingly enter an atmosphere with oxygen deficiency, toxic gases, or combustible dust. This can result in respiratory issues, chemical burns, or, in extreme cases, explosions. Proper monitoring and understanding of the stored materials are crucial to mitigate this risk effectively. Training workers to recognize the signs of a toxic atmosphere and equipping them with proper respiratory protection is essential.

4. Confined Space Entrapment

The confined nature of silos, coupled with machinery for loading and unloading, increases the risk of entrapment. Workers may face challenges related to getting caught in augers, conveyors, or other moving parts. Entrapment can lead to serious injuries or fatalities, emphasizing the importance of thorough safety protocols and machinery checks before entry. Emergency response teams must be well-trained to handle entrapment scenarios to ensure confined space safety in silos.

5. Temperature Extremes

Silo structures, typically located outdoors, expose workers to temperature extremes. During hot weather, workers may experience heat stress, dehydration, and heat-related illnesses. In cold climates, the risk of hypothermia and frostbite becomes significant. Adequate provision of personal protective equipment (PPE) and scheduled breaks are essential to combat these weather-related risks, especially in a confined space like a silo. Moreover, training programs should educate workers on recognizing symptoms of heat- or cold-related illnesses and taking preventive measures.

6. Communication Challenges

The enclosed nature of silos can result in communication challenges. Limited visibility and potential noise from machinery make effective communication difficult. Workers may face delays in emergency response due to these challenges. Implementing clear communication protocols, including the use of signaling devices and regular checks, becomes vital to ensure a swift and coordinated response to any unforeseen events.

7. Material Shifts and Structural Integrity

Silo contents can shift, leading to changes in weight distribution and structural integrity. This poses risks of structural failures or collapses, especially in older or poorly maintained silos. Workers should be aware of signs indicating potential structural issues and follow protocols designed for confined space safety in silos to prevent accidents related to structural failures.

8. Equipment Malfunctions

The machinery used in silos, such as conveyor belts, augers, and ventilation systems, can malfunction, increasing the risk of accidents. Workers may get entangled in moving parts or suffer injuries due to sudden equipment failures. Regular maintenance checks and training on equipment operation and emergency shutdown procedures are crucial to mitigate this risk effectively.

Learnings for Silo Workers

Working in silos demands a specialized skill set and a thorough understanding of confined space safety. This is where our confined space safety training for monitors, entrants, and standby persons comes in, offering silo workers a breadth of knowledge and practical application tools to prioritize confined space safety in silos.

Here’s what you can expect to learn from our course as a silo worker:

1. Risk Identification and Assessment

Silo workers are confronted with a myriad of potential hazards, from atmospheric conditions to equipment-related risks. The training instills a culture of proactive risk identification and assessment. Workers learn to recognize and evaluate risks specific to silos, cultivating a heightened sense of awareness.

Beyond theoretical concepts, the course integrates practical exercises, allowing workers to engage hands-on with risk scenarios commonly encountered in silos. This approach ensures that the knowledge gained is not theoretical but applicable in real-world situations.

2. Atmospheric Monitoring Techniques

Silos are confined spaces with the potential for fluctuating atmospheric conditions, which is why understanding the nuances of atmospheric monitoring is crucial for silo workers. The training provides a deep dive into the operation of atmospheric monitoring equipment, ensuring that workers can effectively use these tools to assess air quality within silos.

Practical simulations replicate the conditions of a silo, allowing workers to practice using monitoring equipment in an environment that closely mirrors their workplace. This hands-on experience enhances their proficiency and confidence in dealing with atmospheric challenges.

3. Effective Ventilation Strategies

Ventilation is a critical aspect of confined space safety, particularly in silos where adequate air circulation can be challenging. Silo workers learn strategies for effective ventilation, considering the unique architecture of silos. From identifying ventilation points to implementing measures for continuous air exchange, workers acquire the skills needed to maintain a safe atmosphere within silos.

The training integrates case studies and success stories where proper ventilation plays a pivotal role in preventing accidents. By contextualizing the importance of ventilation, workers gain a profound understanding of its impact on overall safety.

4. Proper Utilization of Personal Protective Equipment (PPE)

Silo-specific PPE goes beyond the standard gear. Silo workers are trained in the selection, usage, and maintenance of PPE tailored to the confined space challenges encountered in silos. This includes respiratory protection, specialized harnesses, and equipment designed for the specific demands of silo environments.

Practical sessions involve the correct application of silo-specific PPE. Workers gain hands-on experience in donning and doffing equipment, ensuring that they are not only familiar with the gear but can use it correctly in dynamic silo conditions.

5. Lock-Out and Tag-Out Procedures

Machinery within silos poses inherent risks. Silo workers learn the meticulous application of lock-out and tag-out procedures to ensure that machinery is safely shut down and secured before any maintenance or entry activities. The course emphasizes the importance of these procedures in preventing accidents related to equipment operation.

Interactive modules simulate scenarios where lock-out and tag-out procedures are crucial. Silo workers actively engage in exercises that replicate the complexities of silo machinery, reinforcing the significance of these safety measures for thorough confined space safety in silos.

6. Rescue Pre-Planning

Silos present unique challenges for rescue operations. The course covers the development and understanding of rescue pre-plans specific to silo environments. Silo workers learn how to create effective plans for timely and safe rescue operations in case of emergencies.

Simulation exercises involve mock rescue scenarios within silos. Workers actively participate in planning and executing rescue operations, honing their skills in a controlled environment. This practical approach ensures that silo workers are not just familiar with rescue pre-planning but are capable of applying it in high-stakes situations.

7. Understanding Documentation

Among other integral learnings, silo workers will also become adept at reading and understanding documentation such as hazard/risk assessments, work and entry permits, and rescue pre-plans with our confined space safety courses. This skill is crucial for complying with regulations and maintaining a safe work environment.

The training emphasizes the significance of documentation in confined spaces, where clear communication and adherence to protocols are paramount. Case studies showcase instances where thorough documentation played a pivotal role in preventing accidents and ensuring a systematic approach to safety.

8. Emergency Communication Protocols

Communication in confined spaces, especially silos, is notoriously challenging. Silo workers must therefore learn effective communication protocols, including hand signals and device usage. Clear and swift communication is essential for coordinating tasks and responding to emergencies within silos.

The training incorporates communication exercises that mimic silo conditions. Workers practice using communication devices and signals in scenarios that replicate the confined and noisy nature of silos. This practical experience enhances their ability to communicate effectively in challenging silo environments.

9. Psychological Preparedness and Stress Management

Silo work is not just physically demanding; it can also take a toll on mental well-being. Recognizing the psychological challenges of confined space work, this training provides strategies for stress management and maintaining focus. Silo workers develop psychological preparedness for the unique demands of their work.

The interactive sessions planned within our training involve stress management techniques tailored to the realities of silo work. Workers engage in discussions and exercises that address the psychological aspects of confined spaces, fostering resilience and mental preparedness.

Enrol Today!

Since 2008, our experts at Metro Safety have been working towards worker safety across multiple industries in British Columbia. We have since collaborated with the Red Cross to bring several occupational first aid courses applicable in all kinds of spaces, ranging from corporate offices to construction sites.

Our Confined Space Safety Courses stand as a comprehensive guide for silo workers, providing them with the knowledge and skills necessary to navigate the intricate challenges with respect to confined space safety in silos.

To enroll, visit our website to find the confined space safety program that applies to you. You can also access a breadth of resources and guides available on our website, as well as enrol in our fall protection training to address fall hazards in a more rigorous manner. For more information, contact us today!