Worksite injuries are an unfortunate reality, and among the most common incidents are limb fractures and dislocations. Quick and effective response to such injuries is crucial for minimizing damage and ensuring the well-being of the injured party.

In this comprehensive guide, we will explore why limb fractures and dislocations happen at worksites, their signs and symptoms, who is more prone to these incidents, preventive measures, and most importantly, how to respond in the critical moments following an occurrence.

Additionally, we’ll highlight the relevance of Occupational First Aid (OFA) and the courses offered by Metro Safety Training in Surrey.

Section 1: Why Limb Fractures and Dislocations Happen at Worksites

Worksite Hazards

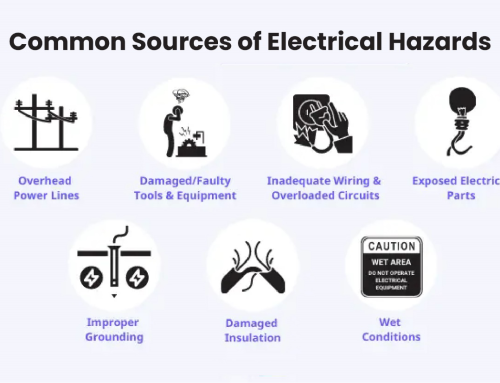

Worksites are dynamic environments with various hazards that significantly contribute to limb fractures and dislocations. Falls, machinery accidents, and incidents involving heavy equipment are common occurrences that pose a considerable risk. Occupational activities, such as manual handling and lifting, also increase the susceptibility to musculoskeletal injuries. Understanding these hazards is crucial for developing effective preventive measures and response strategies.

Risk Factors Leading to Limb Fractures and Dislocations

Falls and Height-Related Risks

One of the primary risk factors for limb fractures at worksites is the potential for falls, especially from elevated surfaces. Construction sites, industrial facilities, and maintenance projects often involve working at heights, making workers susceptible to severe injuries. Uneven surfaces, inadequate fall protection measures, and improper use of ladders or scaffolding contribute to the risk of falls, leading to limb fractures and dislocations.

Machinery Accidents

The operation of heavy machinery and equipment introduces another significant risk factor. Accidents involving machinery can result in traumatic injuries, including limb fractures and dislocations. Lack of proper training, inadequate safety protocols, and failure to use appropriate personal protective equipment amplify the risk associated with machinery-related incidents.

Manual Handling and Lifting

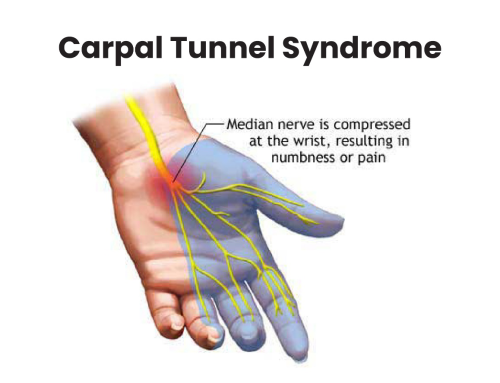

Tasks involving manual handling, lifting, or carrying heavy loads pose a continuous risk to workers. Poor lifting techniques, overexertion, and lack of ergonomic considerations increase the likelihood of musculoskeletal injuries, including fractures and dislocations. Workers involved in repetitive lifting or handling tasks are particularly susceptible to these injuries over time.

High-Impact Activities

Certain occupations involve high-impact activities or working with tools and equipment that generate significant force. For example, individuals in the construction industry using power tools or working with heavy materials face an increased risk of traumatic injuries. The impact of tools or materials can lead to fractures and dislocations, especially if safety precautions are not rigorously followed.

Environmental Hazards

Environmental factors, such as poor lighting, slippery surfaces, or extreme weather conditions, contribute to the risk of limb fractures and dislocations. Inadequate visibility increases the likelihood of accidents, and adverse weather conditions can make worksites more hazardous. Addressing these environmental risk factors is crucial to creating a safer work environment.

Lack of Safety Training and Awareness

Insufficient training and awareness among workers regarding safety protocols and hazard recognition represent a critical risk factor. Workers who are not adequately trained to identify potential risks and respond appropriately are more likely to encounter accidents leading to limb fractures and dislocations. Comprehensive safety training becomes a cornerstone in mitigating this risk factor.

Workplace Fatigue

Fatigue significantly impairs concentration, reaction time, and overall cognitive function, increasing the risk of accidents. Workers experiencing fatigue may be more prone to errors, leading to incidents that result in limb fractures and dislocations. Addressing workplace fatigue through proper scheduling, breaks, and workload management is essential for injury prevention.

Section 2: Signs and Symptoms of Limb Fractures and Dislocations

Physical Indicators

Recognizing the signs and symptoms of limb fractures and dislocations is paramount for a swift and effective response. Visible signs may include deformities, swelling, and unnatural angles, while less obvious symptoms encompass severe pain, an inability to move the affected limb, and potential nerve damage. Awareness of these indicators empowers workers to take immediate action and seek professional medical assistance promptly.

Section 3: Individuals Prone to Limb Fractures and Dislocations

High-Risk Occupations

Certain occupations carry a higher risk of limb fractures and dislocations. Construction workers, industrial laborers, and individuals involved in physically demanding tasks are particularly vulnerable. Factors such as age, pre-existing medical conditions, and the impact of fatigue play a significant role in determining an individual’s susceptibility to these injuries. Recognizing the high-risk nature of certain occupations informs targeted preventive strategies.

Section 4: Preventive Measures for Limb Fractures and Dislocations

Training and Education

Creating a safety-conscious workforce begins with comprehensive training programs. The Occupational First Aid courses offered by Metro Safety Training in Surrey are instrumental in providing the necessary knowledge and skills. Training covers proper lifting techniques, the use of personal protective equipment, and adherence to safety protocols. Education is key to building a culture where preventive measures become ingrained in daily work practices.

Section 5: How to Respond to Limb Fractures and Dislocations

Step-by-Step Response

In critical moments following a limb fracture or dislocation, a systematic and immediate response is crucial.

Assess the Scene

The first step in responding to a limb fracture or dislocation is to assess the scene for safety. Ensure that there are no ongoing hazards that could endanger the responder or the injured individual. Identify potential risks, such as nearby machinery or unstable structures, and take necessary precautions.

Ensure Personal Safety

Before assisting, it is crucial to ensure personal safety. Use personal protective equipment (PPE) if available and approach the injured person with caution. Do not put yourself in harm’s way, especially in situations involving machinery or ongoing hazards.

Call for Professional Medical Assistance

In cases of limb fractures or dislocations, professional medical assistance is essential. Call emergency services immediately to ensure that trained medical professionals can provide the necessary care. While waiting for help to arrive, follow first aid protocols to alleviate pain and minimize further injury.

Immobilize the Affected Limb

Immobilization is a key component of first aid for limb fractures and dislocations. Stabilize the injured limb to prevent further damage and reduce pain. If a fracture is suspected, avoid unnecessary movement of the limb. Use splints or improvised materials, such as boards or rolled-up clothing, to support and immobilize the affected area.

Control Bleeding

In some cases, a fracture or dislocation may result in bleeding. Control any bleeding by applying direct pressure to the wound using a sterile dressing or clean cloth. Elevate the injured limb if possible, as this can help reduce blood flow and minimize bleeding.

Provide Comfort and Reassurance

Experiencing a limb fracture or dislocation can be traumatic for the injured individual. Provide comfort and reassurance while awaiting professional medical assistance. Stay calm, offer words of support, and encourage the person to remain as still as possible.

Monitor and Record Vital Signs

While waiting for professional help, monitor the injured person’s vital signs. Check for signs of shock, such as pale skin, rapid breathing, or a weak pulse. Keep the individual warm by covering them with a blanket, but avoid overheating.

The Occupational First Aid courses offered by Metro Safety Training in Surrey cover these essential first-aid strategies, empowering individuals with the knowledge and skills needed to respond effectively to limb fractures and dislocations in the workplace. By following these steps and receiving proper training, first aid responders contribute to a safer and more secure work environment.

Section 6: OFA Courses Offered by Metro Safety Training in Surrey

Occupational First Aid Level 1

OFA Level 1 provides fundamental skills, including CPR, wound care, and initial injury assessment. It lays the foundation for individuals to respond confidently to a variety of workplace injuries, including limb fractures and dislocations.

Occupational First Aid Level 2

OFA Level 2 builds on the foundational knowledge, introducing advanced first aid techniques. Topics include spinal injury management, oxygen therapy, and advanced wound care, enhancing the responder’s ability to handle more complex medical situations.

Occupational First Aid Level 3

OFA Level 3 offers comprehensive training in managing multiple casualties, advanced life support, and in-depth trauma care. This level is designed for individuals who need a higher level of proficiency in first aid response, making them valuable assets in workplaces with elevated risks.

Occupational First Aid Level 3 Pro Renewal

Regular renewal is essential to ensure first aid responders stay up-to-date with the latest protocols and techniques. OFA Level 3 Pro Renewal refreshes individuals who have previously completed Level 3 training, reinforcing their skills and knowledge.

Fall Protection

The Fall Protection course focuses on preventing falls, a common hazard leading to limb fractures. Participants learn proper use of fall protection equipment, hazard assessment, and emergency response procedures, enhancing their ability to create a safer work environment.

Confined Space Safety for Monitor and Entrant

Specialized training in Confined Space Safety equips individuals with the skills needed to monitor and enter confined spaces safely. This course addresses the unique challenges associated with confined spaces, reducing the risk of injuries, including limb fractures and dislocations.

Metro Safety Training in Surrey stands as a reliable partner in this journey, offering a range of courses designed to empower individuals with the knowledge and skills needed to respond to emergencies and enhance overall workplace safety. Call us today.