If you’re part of the bustling world of warehouse work, you know it’s a place where efficiency meets hustle. But let’s not forget, it’s also a place where safety should be front and center. Today, we’re going to chat about something super important – warehouse safety protocols for warehouse employees.

Let’s dive into essential tips and tricks to keep you safe on the job.

So, let’s dive in and explore warehouse safety protocols in depth!

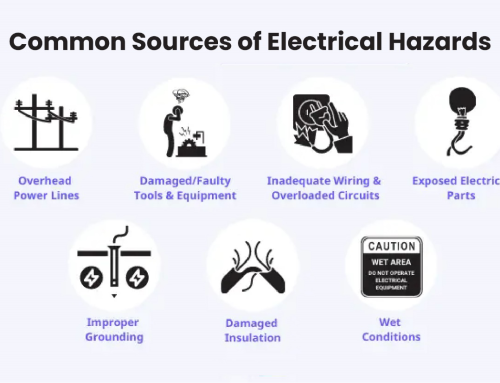

Identifying Common Risks

First things first, let’s talk about what you’re up against in a warehouse setting. It’s a dynamic place, and with that comes a variety of risks. We’re looking at things like slips, trips, and falls – classic but still a big deal.

Then there’s the whole world of machinery and equipment; forklifts and conveyor belts aren’t exactly fluffy pillows, right?

And don’t forget about the potential for lifting injuries or mishaps with stacked items. Knowing these risks is your first step to staying safe.

The Importance of Awareness

Awareness is your best friend in a warehouse. It’s all about keeping your eyes open and staying sharp. A spill on the floor, a box placed haphazardly, or even a loose cable can turn into an accident if you’re not paying attention.

The key is to always be aware of your surroundings and to expect the unexpected – because in a warehouse, anything can happen.

Basic Rules for Everyday Safety

Alright, let’s get down to the nitty-gritty of everyday safety in the warehouse. There are some basic rules that everyone should stick to. First up, always wear your personal protective equipment (PPE) – think helmets, gloves, and safety glasses. They’re like your personal armor against workplace hazards. Next, keep those walkways clear.

A clutter-free path is a safe path. And remember, if you see a spill, don’t just walk by; make it your mission to clean it up or report it.

The Role of PPE

Diving a bit deeper into PPE, it’s not just about wearing it but wearing it right. Make sure your safety gear fits well and is in good condition. A helmet that’s too loose? Not going to do much in a pinch. And those safety shoes? They’re not just a fashion statement—they’re there to protect your toes from heavy objects.

Safe Handling of Equipment and Machinery

Operating Machinery with Care

Now, for the big stuff – machinery and equipment. Operating a forklift or a pallet jack isn’t like driving a car. There are specific rules and training for a reason.

Always follow the operational guidelines and never take shortcuts.

Regular checks and maintenance are also part of the deal. A well-oiled machine is a safer machine.

Preventing Equipment-Related Accidents

Be alert to the sounds and movements around you. And communication is key – use signals or verbal cues to let others know where you are and what you’re doing.

It’s like a dance, and everyone needs to be in sync to avoid stepping on each other’s toes.

Developing a Safety-First Mindset

Creating a safe warehouse environment starts with a mindset. It’s about building a culture where safety isn’t just a poster on the wall but a daily practice. This means having clear safety protocols that everyone understands and follows.

It’s not just about the rules, though; it’s about why they matter. When everyone gets the ‘why’ behind the ‘what,’ following safety protocols becomes second nature.

The Power of Regular Safety Training

Training isn’t just a one-time thing; it’s an ongoing journey. Regular safety training sessions are crucial. They keep everyone up-to-date on the best practices and refresh their knowledge on how to handle different scenarios. Think of it as a workout for your safety muscles – the more you train, the stronger they get.

Occupational First Aid in the Warehouse

Being Prepared for Emergencies

Despite all the precautions, accidents can still happen. That’s where occupational first aid comes in. It’s about having the skills to effectively respond when things go south.

Learning to administer first aid is a skill set that every warehouse worker should have in their toolbox.

Setting Up First Aid Stations

A well-equipped first aid station is a must-have in any warehouse. It should be easily accessible and stocked with all the essentials – bandages, antiseptics, splints, you name it.

And it’s not just about having the station; it’s about making sure everyone knows where it is and how to use it.

Emergency Response and Evacuation Procedures

Planning for the Unexpected

In a warehouse, being prepared for emergencies is non-negotiable. This means having a solid emergency response plan in place. It’s not just about dealing with the immediate aftermath of an incident but also ensuring everyone’s safe evacuation if needed.

Think fire drills, but for all kinds of emergencies, you might encounter in a warehouse.

Conducting Regular Evacuation Drills

Practice makes perfect, right? Regular evacuation drills are key. They help everyone understand what to do and where to go in case of an emergency. It’s important that these drills are taken seriously – no casual strolling to the exit. Speed and efficiency are of the essence here.

Handling Specific Emergencies

Every type of emergency requires a different response. For instance, the way you handle a chemical spill is different from a fire breakout. Make sure your emergency plan covers these scenarios with clear, step-by-step instructions.

And always have a designated emergency response team – a group of trained individuals who can take charge when things go awry.

The Role of Regular Safety Checks

Keeping a warehouse safe is an ongoing process, and regular safety inspections play a huge part in this. Think of these checks as your warehouse’s health check-up. They’re about spotting potential hazards before they turn into accidents.

This could be anything from checking that aisles are clear to ensuring machinery is in good working order.

Conducting Thorough Audits

Audits are like deep dives into your warehouse’s safety practices. They’re more comprehensive than your daily or weekly checks. An audit looks at everything from how well safety protocols are being followed to the condition of equipment and tools.

It’s a chance to identify areas for improvement and reinforce what’s working well.

Learning and Improving from Audits

The real value of audits comes from what you do with the findings. It’s about taking those insights and turning them into action. It’s a cycle of continuous improvement.

Fostering a Shared Responsibility for Safety

Safety in a warehouse isn’t just the responsibility of the managers or the safety officers; it’s a team effort. Creating a culture of safety means everyone, from the newest recruit to the most experienced worker, takes an active role in maintaining a safe environment.

It’s about looking out for each other and speaking up when something doesn’t seem right.

Encouraging Open Communication

Talk to the employees about safety culture. Encourage them to share their suggestions and concerns. Maybe they’ve noticed a recurring hazard or have an idea for improving safety in a particular area. Regular team meetings can be a great platform for these discussions. Remember, the best safety ideas often come from the people on the front lines.

Recognizing and Rewarding Safe Practices

Positive reinforcement can go a long way in promoting safe behavior. This could be through formal recognition programs or simple acts of acknowledgment. It sends a clear message: safety is valued here.

Remember, safety in the warehouse is not just about following rules; it’s about creating an environment where everyone feels responsible and empowered to contribute to a safer workplace.

Incorporating regular training, emergency preparedness, safety inspections, and leveraging technology are all key components in building this safe environment. But the most important element? That’s you and your colleagues.

So, stay vigilant, keep communicating, and never stop learning about how to stay safe. And if you’re looking to enhance your knowledge or need more resources on warehouse safety, Metro Safety Training is here to help.

With a range of courses and expert guidance, they help you navigate the warehouse safely and confidently. Here’s to a safer workplace for everyone!