Electricity is an indispensable part of modern life, powering our homes, workplaces, and industries. However, it also presents significant hazards, particularly for those who work directly with power sources. Electricians and individuals in related roles face the daily challenge of navigating electrical hazards to ensure safety and prevent accidents.

In this guide, we’ll delve into the crucial aspects of electrical hazard awareness and explore effective safety measures to protect against electric shock and arc flash incidents.

Understanding Electrical Hazards

1. Electric Shock

Electric shock occurs when the human body becomes part of an electrical circuit, allowing current to flow through it. The severity of electric shock depends on several factors, including the amount of current, the duration of exposure, and the path the current takes through the body. It’s important to note that even low levels of electric current can cause involuntary muscle contractions, making it difficult or impossible for a person to release the source of the shock.

Electric shock can lead to various injuries, including burns, muscle and nerve damage, cardiac arrest, and even death. The effects of electric shock can be immediate or delayed, depending on the circumstances. For example, individuals may experience internal organ damage or neurological complications after the initial shock.

2. Arc Flash

Arc flash is an instantaneous and catastrophic event triggered by an electric arc, a phenomenon where electrical current moves through the air between conductors or to the ground. This discharge of energy generates a sudden burst of intense heat, blinding light, and pressure waves, creating an extremely hazardous situation for individuals in close proximity.

These incidents can arise from a multitude of factors, including equipment malfunction, inadvertent contact with live components, or deviations from safe work practices. The resulting heat from an arc flash can surpass temperatures hotter than the surface of the sun, leading to severe burns and potentially igniting nearby combustible materials.

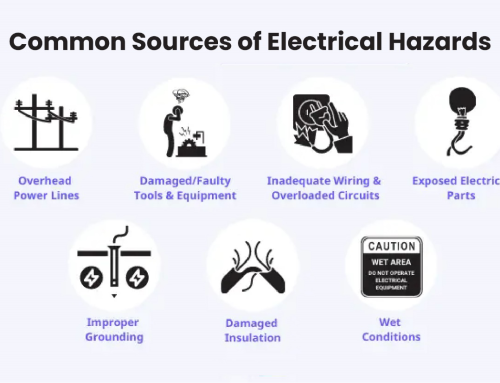

Identifying Electrical Hazards

Recognizing potential electrical hazards is the first line of defense in maintaining a safe work environment. Electricians and individuals working with power sources must be vigilant in identifying and addressing hazards before they escalate into dangerous situations. Here are key areas to consider when identifying electrical hazards:

1. Exposed Wiring and Damaged Insulation:

Exposed wiring, damaged insulation, or frayed cables present significant risks of electric shock and short circuits. Regular inspections of electrical systems and equipment are crucial to identify signs of wear and tear. Any exposed wiring or insulation damage should be addressed promptly to prevent accidents and ensure electrical safety.

2. Overloaded Circuits:

Overloading electrical circuits can lead to overheating, fires, and equipment failures. It’s essential to avoid plugging too many devices into a single outlet or circuit, as this can exceed the capacity of the wiring and increase the risk of electrical hazards. Signs of overloading include flickering lights, frequently tripped circuit breakers, or warm outlets.

3. Faulty Equipment:

Malfunctioning or improperly maintained electrical equipment poses a significant electric hazard in the workplace. Regular inspection and maintenance of tools, machinery, and appliances are essential to identify potential issues early on. Any signs of damage, unusual noises, or erratic behavior should be investigated and addressed by qualified personnel to prevent accidents and ensure equipment reliability.

4. Wet Conditions:

Water and electricity are a dangerous combination. Working with electrical equipment in wet or damp conditions significantly increases the risk of electric shock and short circuits. It’s crucial to exercise caution and implement appropriate safety measures when working in environments where moisture is present. This includes using waterproof electrical equipment, wearing insulated gloves and footwear, and ensuring proper grounding of electrical systems.

Implementing Safety Measures

Now that we’ve identified common electrical hazards, let’s explore practical safety measures to mitigate risks and promote a culture of safety:

1. Training and Education:

Comprehensive training and education programs serve as the foundation of electrical safety in British Columbia workplaces. These programs should not only cover theoretical aspects of electrical hazards but also include practical demonstrations and simulations to reinforce learning.

Training sessions should be tailored to different roles and responsibilities, ensuring that employees understand their specific risks and responsibilities regarding electrical safety. WorkSafeBC offers resources and guidelines for developing effective training programs tailored to the unique needs of various industries and workplaces.

Regular refresher courses and ongoing education are essential to keep employees up-to-date with the latest safety regulations, technologies, and best practices. Training should be interactive and engaging, encouraging active participation and knowledge retention. Employers should also provide opportunities for certification and professional development in electrical safety to enhance employees’ skills and qualifications.

2. Personal Protective Equipment (PPE):

Personal protective equipment (PPE) plays a crucial role in safeguarding workers against electrical hazards. When selecting PPE, employers must ensure that it meets relevant safety standards and regulations.

Insulated gloves, for example, should provide adequate protection against electrical shock while allowing for dexterity and comfort. Safety glasses with side shields protect the eyes from flying debris and potential arc flash incidents.Flame-resistant clothing is designed to minimize the risk of burns in the event of an arc flash or electrical fire.

The selection of PPE should be based on a thorough risk assessment of the work environment and the specific hazards present. Employees must receive training on the proper use, care, and maintenance of PPE to ensure its effectiveness. Regular inspections and replacements are necessary to address wear and tear and maintain the integrity of the protective gear.

3. Lockout/Tagout Procedures:

Lockout/tagout procedures are critical for preventing hazardous energy releases during maintenance, repair, or servicing of equipment in British Columbia workplaces. These procedures involve isolating energy sources, securing them with lockout/tagout devices, and verifying that equipment is de-energized and safe to work on.

Proper implementation of lockout/tagout procedures requires clear communication, standardized protocols, and employee training.Employees should receive comprehensive training on lockout/tagout procedures, including the identification of energy sources, the proper application of lockout/tagout devices, and the importance of following established protocols.

Supervisors and authorized personnel must oversee and verify lockout/tagout procedures to ensure compliance and safety. Regular audits and reviews help identify areas for improvement and ensure that lockout/tagout procedures remain effective over time.

4. Regular Inspections and Maintenance:

Regular inspections and maintenance are essential components of electrical safety programs in workplaces across the world. Electrical systems, equipment, and wiring should be inspected regularly by qualified personnel to identify potential hazards and address them proactively.

Inspections may include visual assessments, testing, and diagnostic procedures to detect signs of wear, damage, or deterioration.Employers should establish a schedule for routine maintenance activities based on manufacturer recommendations, industry standards, and regulatory requirements.

Maintenance procedures should be documented, and records of inspections and repairs should be maintained for compliance and accountability purposes. Any identified hazards or deficiencies should be addressed promptly to prevent accidents and ensure the continued reliability of electrical systems.

5. Safe Work Practices:

Safe work practices encompass a wide range of behaviors and procedures designed to minimize the risk of electrical accidents and injuries. These practices include proper grounding techniques, de-energizing circuits before maintenance or repair work, and using insulated tools when working on live electrical systems.

Employees should receive training on safe work practices specific to their job roles and responsibilities. This training should emphasize the importance of situational awareness, hazard recognition, and adherence to established safety protocols. Supervisors and management should lead by example and promote a culture of safety through consistent enforcement of policies and procedures.

Regular safety meetings, toolbox talks, and job hazard analyses help reinforce safe work practices and encourage open communication about potential hazards and concerns. Employees should be empowered to speak up about unsafe conditions or practices without fear of reprisal, fostering a collaborative approach to safety in the workplace.

6. Emergency Preparedness:

Emergency preparedness is a cornerstone of electrical safety programs in British Columbia workplaces. Employers must develop and communicate clear emergency response plans outlining procedures for addressing electrical incidents and injuries. These plans should include protocols for administering first aid, evacuating personnel, and contacting emergency services.

Employees should be trained on emergency response procedures, including recognizing signs of electrical shock or injury and initiating appropriate emergency interventions. Regular drills and exercises help familiarize employees with emergency protocols and ensure that they can respond effectively in high-stress situations.

Emergency response plans should be reviewed and updated regularly to reflect changes in personnel, equipment, or workplace conditions. Employers should also provide access to first aid supplies, emergency contact information, and communication devices to facilitate prompt response and coordination during emergencies. Collaboration with local emergency services and authorities can further enhance emergency preparedness efforts and ensure a coordinated response to critical incidents.

Connect with Metro Safety’s Experts in British Columbia!

With more than 15 years of experience in the training field, Metro Safety is proud to offer its top-tier training courses to residents of British Columbia! From first aid trainings to workplace safety courses, we have specially crafted each course to help you gain the skills to perform life-saving interventions in a broad range of settings, including for when you’re working with electrical hazards.

Explore our occupational first aid courses, available in three levels of difficulty. You might also want to explore our confined space safety programs, as well as our training on fall protection. Alternatively, you may find helpful blogs and resources on our website to support your learning.

Visit today and book your slots before they run out!