Confined spaces – tunnels, shafts, tanks, and vaults – are a common feature in underground operations, and working within them requires a heightened level of safety awareness.

For underground workers, proper confined space PPE (Personal Protective Equipment) is not just an option – it’s a non-negotiable necessity.

Continue reading to understand the essential confined space PPE for underground workers and the importance of each piece in mitigating risks and ensuring a safe working environment.

Why Confined Space PPE Matters

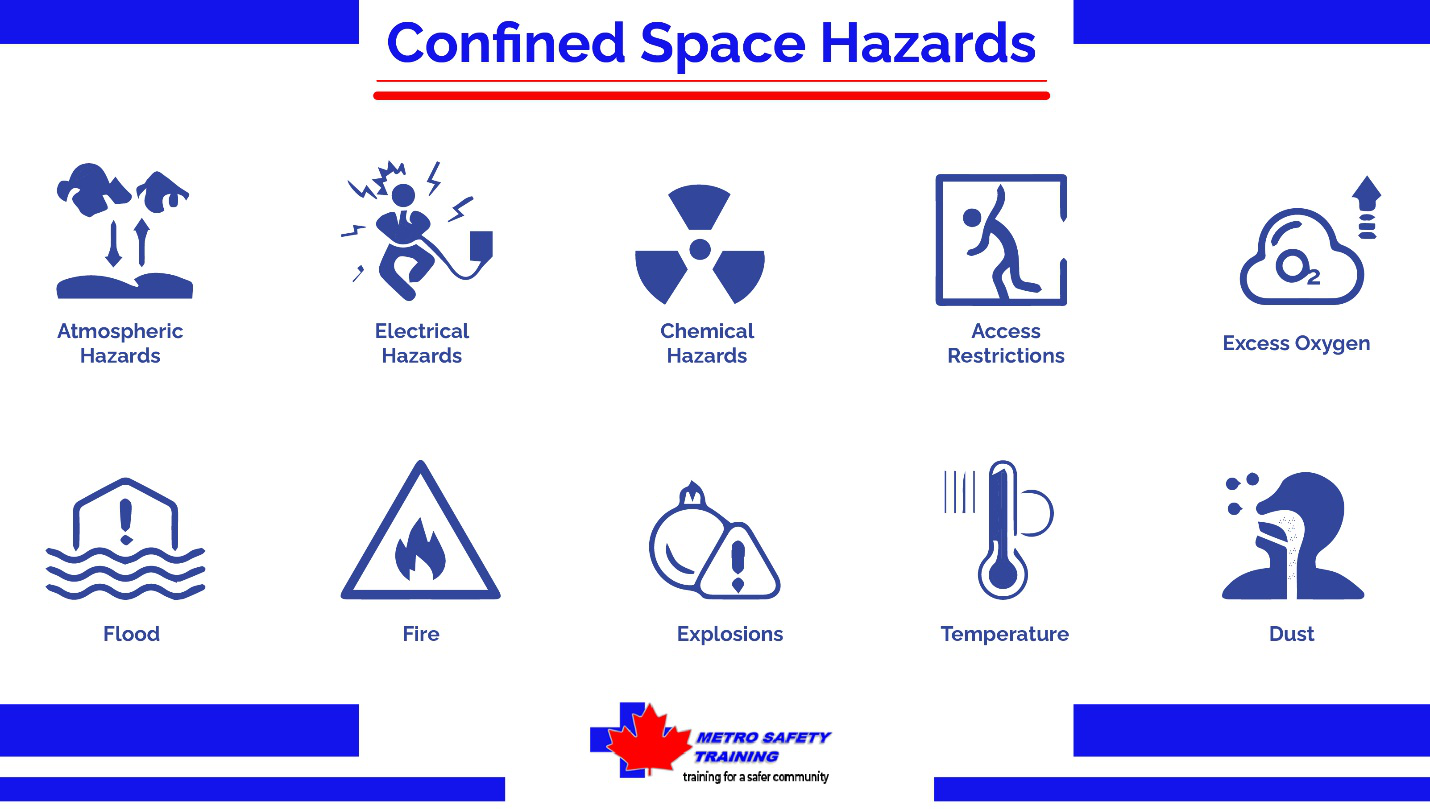

Confined spaces pose a multitude of hazards, including:

- Atmospheric hazards:Lack of oxygen, presence of toxic gases, and combustible dust are all potential threats.

- Engulfment hazards:Flowing liquids, loose materials, or collapsing structures can engulf workers.

- Falling hazards:Uneven terrain, ladders, and working at heights increase the risk of falls.

- Impact hazards:Moving equipment, falling objects, and electrical hazards pose a threat of injuries.

- Heat stress or cold stress:Underground environments can have extreme temperatures, leading to heatstroke or hypothermia.

Confined space PPE acts as a critical barrier between workers and these dangers. It minimizes exposure to harmful elements, protects from physical injuries, and provides the means for safe entry, work execution, and emergency evacuation.

Essential Confined Space PPE for Underground Workers

The unforgiving environment of underground spaces demands a robust safety protocol. Confined spaces, in particular, pose a multitude of hazards that necessitate a specific set of personal protective equipment (PPE) for workers.

This PPE acts as a critical line of defense, safeguarding them from the dangers lurking beneath the surface.

let’s develop a deeper understanding of confined space PPE for underground workers, exploring the specific functions and considerations for each piece:

Respiratory Protection

- Air-purifying respirators (APRs)

These are the workhorses for dust and particulate control. They come with interchangeable filters designed to target specific contaminants.

- Filter Selection

Choosing the right filter is paramount. N-rated filters capture dust and non-oily particulates, while R- or P-rated filters offer additional protection against oil mists or aerosols. Combination filters (e.g., N95-R) provide a broader spectrum of protection.

- Fit Testing

A proper fit test ensures a tight seal around the face, preventing contaminated air from leaking in. Different respirator styles (e.g., half-mask, full-face) exist, and the optimal choice depends on user comfort and the specific hazard.

- Self-Contained Breathing Apparatus (SCBA)

When the oxygen level dips below 19.5% or contaminants are unknown/immediately dangerous to life or health (IDLH), SCBAs become essential.

- Types of SCBA:There are two primary types: pressure-demand and positive pressure. Pressure-demand units supply air only upon inhalation, while positive pressure units maintain a constant positive pressure inside the mask, preventing inward leakage.

- SCBA Training: SCBA use requires specialized training due to the critical nature of the equipment. Workers must be proficient in donning, doffing, and operating the SCBA safely and efficiently, especially in low-visibility or stressful situations.

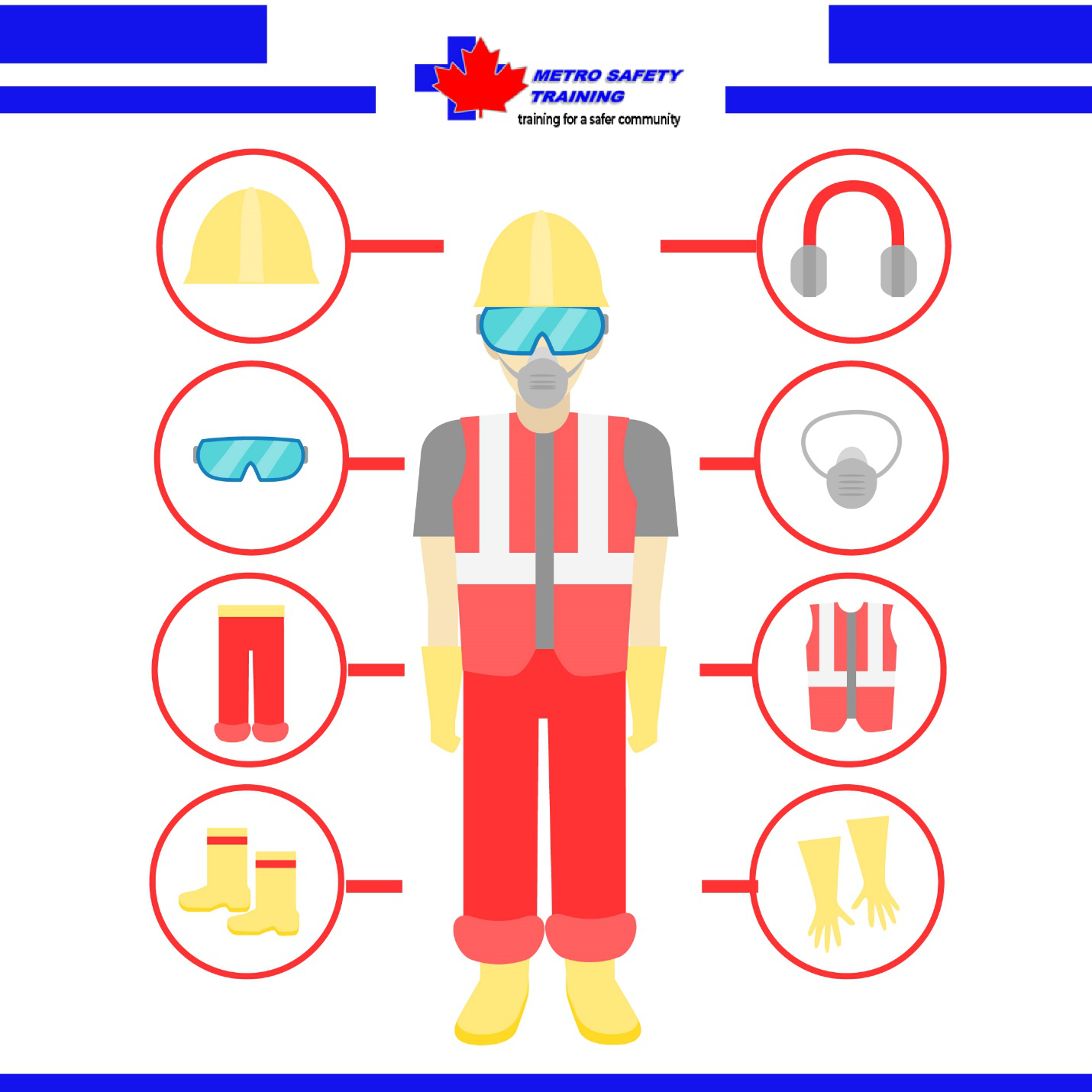

Head Protection

- Hard Hats

These are non-negotiable in confined spaces with the risk of falling objects, bumps against low clearances, or electrical hazards.

- Impact Rating

Consider the hard hat’s impact rating (e.g., Type I or Type II) based on the potential for high-impact or low-impact strikes.

- Headlamp Integration

Some hard hats offer integrated headlamp slots or clips, providing a convenient hands-free lighting solution.

Eye and Face Protection

- Safety Glasses or Goggles

Protect the eyes from dust, debris, splashes of liquids or chemicals, and flying objects.

- Anti-Fog Features

For humid environments, consider safety glasses with anti-fogging coatings to maintain clear vision.

- Goggle Options

For tasks with a high splash risk, full-face goggles offer superior protection.

- Prescription Safety Glasses

Workers who wear prescription glasses can opt for safety glasses with corrective lenses or over-the-glasses styles that fit comfortably over their existing glasses.

Body Protection

- Coveralls

These provide a vital barrier against abrasions, cuts, heat, chemicals, and dust.

- Material Selection

Flame-retardant coveralls made from durable materials like cotton or Nomex are ideal for underground environments.

- High-Visibility Options

In low-light conditions, consider coveralls with reflective stripes to enhance worker visibility.

- Knee Pads

For tasks requiring extended periods of kneeling or crawling, integrated knee pads offer additional comfort and protection.

Hand Protection

- Gloves

The specific glove type depends on the anticipated hazards.

- Chemical-Resistant Gloves

When handling chemicals, choose gloves made from materials like nitrile, butyl, or Viton, offering varying degrees of protection against different chemicals. Ensure the gloves are compatible with the specific chemicals encountered at the worksite.

- Cut-Resistant Gloves

For tasks involving sharp objects, consider cut-resistant gloves made from Kevlar or other high-performance fibers.

- Dexterity

The level of dexterity needed for the task should also be considered. Thicker gloves with higher cut resistance might compromise dexterity, so finding a balance is crucial.

Foot Protection

- Safety Boots

These safeguard feet from punctures, falling objects, electrical hazards, and extreme temperatures.

- Steel Toes

Opt for steel-toed boots to protect against falling objects or accidental foot impacts.

- Slip-Resistant Soles

Soles with good traction are essential to prevent slips and falls on potentially uneven or wet surfaces.

- Insulation

For environments with extreme temperatures, consider boots with insulation to protect against heat or cold stress.

These offer additional protection for the top of the foot from falling objects or crushing hazards.

Fall Protection

- Harnesses

Full-body harnesses are mandatory for working at heights within confined spaces or in situations with a risk of falls.

- Features

Look for harnesses with multiple D-rings for attaching lifelines, retrieval lines, and other fall arrest equipment. Consider comfort features like padded leg straps and breathable materials for extended wear.

- Lanyards and Lifelines

These connect the harness to a secure anchor point outside the confined space.

- Double Lanyard System

A double lanyard system is often recommended for confined space entry. This provides redundancy in case one lanyard fails.

- Self-Retracting Lifelines (SRLs)

SRLs automatically retract and lock, offering greater freedom of movement while arresting falls.

Communication Devices

- Two-way Radios or Other Communication Devices

Maintaining constant communication with a standby attendant outside the confined space is vital.

- Durability

Radios should be intrinsically safe for use in potentially flammable atmospheres.

- Hands-Free Options

Consider hands-free headsets or earpieces for convenient communication while working.

- Backup Communication

Having a backup communication method (e.g., whistles, signal mirrors) is advisable in case of radio failure.

Lighting

- Headlamps or Intrinsically Safe Flashlights

Provide illumination for navigating confined spaces, inspecting equipment, and identifying hazards.

- Intrinsically Safe Features

Underground environments might harbor flammable gases or dust. Intrinsically safe headlamps and flashlights are specifically designed to prevent sparks or heat generation that could ignite such materials.

- Beam Options

Consider headlamps with adjustable beam patterns (e.g., spot, flood) for optimal versatility in different situations.

Additional Considerations

Monitoring Equipment

Gas detectors are crucial for assessing oxygen levels and the presence of hazardous gases like carbon monoxide, methane, or hydrogen sulfide. Choose detectors appropriate for the specific contaminants anticipated at the worksite.

Retrieval Equipment

Tripods, davits, and winches can be used to safely retrieve workers from confined spaces in case of emergencies. These should be rated for the weight capacity of a fully equipped worker.

Choosing the Right PPE

The specific type of confined space PPE needed will vary depending on the specific job site and potential hazards.

A thorough risk assessment should be conducted before each entry to identify the dangers present and determine the appropriate PPE selection.

These are the following things you must consider:

- Proper Fit: All PPE should fit comfortably and not restrict movement. Ill-fitting equipment can be ineffective and even dangerous.

- Inspection and Maintenance:Regularly inspect PPE for damage or wear and tear. Replace worn-out equipment promptly. Following the manufacturer’s recommendations for cleaning and storage is crucial for maintaining PPE integrity.

- Training:Workers must be properly trained on how to use and maintain their PPE. This includes donning and doffing procedures, proper inspection techniques, and limitations of specific equipment.

Empowered with the right knowledge and equipment, underground workers can navigate confined spaces with confidence.

But safety doesn’t stop at PPE. Proper training is crucial, and Metro Safety Training can equip you with the skills you need to enter confined spaces safely.

Our Confined Space Safety for Monitor and Entrant course provides comprehensive training for both those entering confined spaces and those responsible for monitoring them. This course is essential for anyone working in underground environments where confined spaces are present.

Contact us today if you need OFA 2 evening courses in Surrey, Fall Protection Courses, or other First aid training courses in Surrey!