Approximately, 429,000 workers in Canada are exposed to silica. However, despite its ubiquity and utility, silica poses significant health risks when its dust particles are inhaled.

Understanding the hazards of silica exposure is crucial for safeguarding the health of workers in several industries.

Let’s look into the nature of silica, the industries most affected, the health risks associated with silica exposure, and effective protective measures to mitigate these risks.

Understanding Silica

Silica, or silicon dioxide (SiO2), is one of the most common minerals on Earth. It exists in two forms: crystalline and amorphous. The crystalline form, particularly quartz, is a significant concern in occupational settings.

When materials containing crystalline silica are cut, ground, or disturbed, they produce fine dust particles that can be easily inhaled. Once inhaled, these particles can lodge deep in the lungs, leading to serious health problems.

In the context of occupational health, the hazards of silica exposure primarily stem from the inhalation of respirable crystalline silica (RCS). RCS particles are small enough to bypass the respiratory system’s natural defenses and penetrate deep into the lungs, causing inflammation, scarring, and other long-term health issues.

Which Industries Mostly Face the Hazards of Silica Exposure?

Silica exposure is prevalent across various industries, particularly those involving significant amounts of dust generation.

Here are some key sectors where the hazards of silica exposure are most pronounced:

Construction

Construction workers are among the most at risk for silica exposure due to activities such as cutting, sawing, drilling, and crushing materials like concrete, brick, and stone. Demolition work also releases significant amounts of silica dust.

Read OSHA’s RCS standards for the construction industry.

Mining and Quarrying

The mining and quarrying industries expose workers to silica dust during the extraction, crushing, and processing of ores and minerals. This is especially true for operations involving coal, gold, and other hard rock mining.

Manufacturing

Manufacturing processes that involve silica include the production of glass, ceramics, and concrete products. Workers in these industries are exposed to silica dust during material handling, shaping, and finishing operations.

Oil and Gas

In the oil and gas industry, silica is used in hydraulic fracturing (fracking) to keep fractures open and facilitate the flow of oil and gas. The handling and processing of silica sand in fracking operations can expose workers to high levels of silica dust.

Foundries

Foundry workers are exposed to silica during the casting process, particularly when handling sand molds and cores, which contain high levels of crystalline silica.

All Hazards of Silica Exposure – Explained

The hazards of silica exposure are primarily associated with respiratory health, but the impacts can be far-reaching. Understanding these hazards is essential for implementing effective protective measures.

Silicosis

Silicosis is a progressive, incurable lung disease caused by the inhalation of crystalline silica dust. It occurs in three forms:

- Chronic Silicosis:Develops after 10+ years of low to moderate exposure. Symptoms include shortness of breath, cough, and fatigue.

- Accelerated Silicosis:Occurs after 5-10 years of high exposure. Symptoms are similar to chronic silicosis but progress more rapidly.

- Acute Silicosis:Develops within a few weeks or months of extremely high exposure. Symptoms include severe shortness of breath, cough, weight loss, and fatigue. This form can be rapidly fatal.

Lung Cancer

There is a well-documented link between silica exposure and lung cancer. Workers exposed to crystalline silica have an increased risk of developing lung cancer due to the chronic inflammatory responses triggered by the inhaled particles.

Chronic Obstructive Pulmonary Disease (COPD)

Silica exposure is also associated with chronic obstructive pulmonary disease (COPD), a group of lung conditions that cause breathing difficulties, including emphysema and chronic bronchitis. COPD results from long-term exposure to irritants, including silica dust, that damage the lungs and airways.

Kidney Disease

Recent studies have shown a correlation between silica exposure and kidney disease. Silica dust can cause inflammation and damage to kidney tissues, leading to conditions such as chronic kidney disease and end-stage renal disease.

Autoimmune Disorders

Exposure to silica has been linked to several autoimmune disorders, including rheumatoid arthritis, systemic lupus erythematosus, and scleroderma. Silica particles can trigger immune system reactions that lead to these chronic diseases.

How to Protect Against Hazards of Silica Exposure?

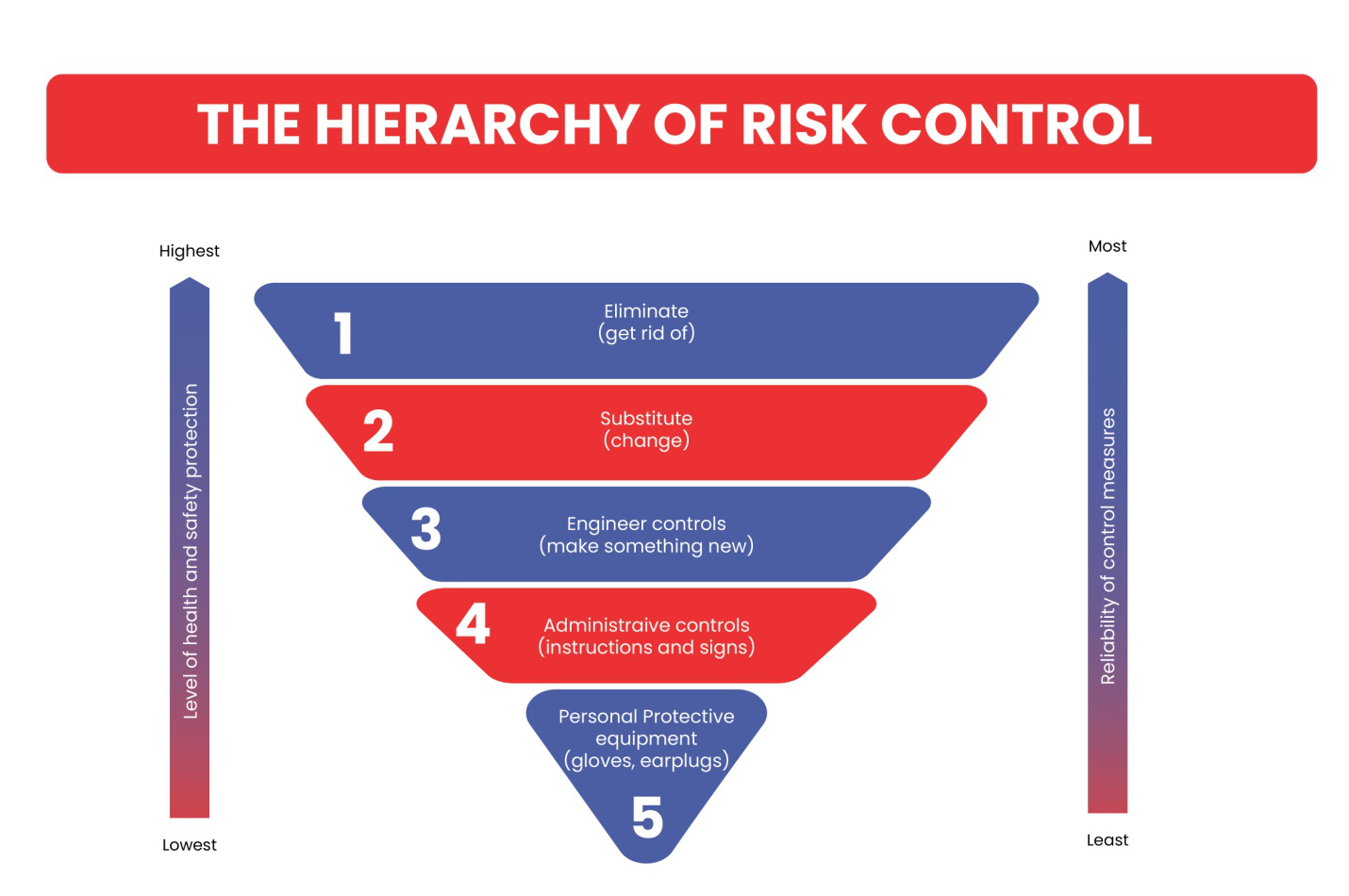

Protecting workers from the hazards of silica exposure requires a comprehensive approach that includes engineering controls, administrative measures, personal protective equipment (PPE), and training.

Engineering Controls

Engineering controls are the most effective means of reducing silica exposure. These controls involve modifying equipment and processes to minimize the generation and release of silica dust. Examples include:

- Wet Methods:Using water to suppress dust during cutting, grinding, and drilling operations.

- Local Exhaust Ventilation:Installing ventilation systems that capture and remove silica dust at its source.

- Enclosures and Barriers:Enclosing dust-producing equipment and processes to contain silica dust.

Administrative Controls

Administrative controls focus on changing workplace practices and policies to reduce exposure. These measures include:

- Work Scheduling:Rotating workers to limit their exposure time in high-risk areas.

- Housekeeping:Implementing rigorous cleaning protocols to remove settled dust from work surfaces and floors.

- Training and Education:Providing comprehensive training on silica hazards, safe work practices, and the correct use of control measures and PPE.

Personal Protective Equipment (PPE)

While engineering and administrative controls are preferred, PPE is essential for providing additional protection. Key PPE for silica exposure includes:

- Respirators:Properly fitted respirators that meet occupational safety standards can protect workers from inhaling silica dust. The selection of respirators should be based on the level of exposure and the specific work environment.

- Protective Clothing:Wearing disposable or washable protective clothing can prevent silica dust from being carried off-site on workers’ clothing.

Health Monitoring

Regular health monitoring and medical examinations for workers exposed to silica are crucial. Early detection of silicosis, lung cancer, and other silica-related diseases can improve outcomes through timely intervention and treatment.

Methods to Reduce Silica Exposure

Reducing silica exposure requires a combination of strategies tailored to the specific workplace and processes involved. Here are some effective methods:

Substitution

Where possible, substituting materials containing crystalline silica with safer alternatives can significantly reduce exposure. For example, using materials like aluminum oxide or silicon carbide instead of silica in abrasive blasting operations can lower the risk.

Process Modification

Modifying work processes to generate less dust is an effective strategy. This can include using pre-fabricated materials that require less cutting or grinding on-site or implementing automated systems that reduce the need for manual handling of silica-containing materials.

Maintenance of Control Measures

Regular maintenance and inspection of dust control systems are essential to ensure their effectiveness. This includes checking ventilation systems, repairing leaks, and ensuring that water suppression systems are functioning correctly.

Worker Training and Education

Continuous training and education on silica hazards and safe work practices are critical. Workers should be informed about the risks of silica exposure, how to recognize symptoms of silica-related diseases, and the importance of adhering to control measures and using PPE correctly.

Monitoring and Assessment

Conducting regular air monitoring and exposure assessments can help identify high-risk areas and evaluate the effectiveness of control measures. This data can guide further improvements in workplace practices and controls.

Community and Workplace Awareness

Raising awareness about the hazards of silica exposure extends beyond the workplace. Employers should engage with workers, unions, and health and safety committees to foster a culture of safety and health. Public awareness campaigns can also help inform the broader community about the risks associated with silica exposure and the importance of protective measures.

Metro Safety Understands the Hazards of Silica Exposure

Metro Safety Training stands at the forefront of occupational health and safety education in Canada, recognizing the critical importance of mitigating the hazards of silica exposure.

Our Asbestos/Lead/Silica Awareness program provides in-depth training for individuals who enter and work in spaces where exposure to these hazardous materials is a concern.

The program’s syllabus and instructional materials are meticulously designed to comply with the WorkSafeBC Occupational Health and Safety Regulation Part 6, ensuring that all content is relevant, up-to-date, and adheres to the highest safety standards.

In addition to the Asbestos/Lead/Silica Awareness program, we also offer a variety of courses designed to address a wide range of occupational safety concerns. Each course is developed with a focus on practical knowledge and real-world application, ensuring that participants are well-prepared to handle safety challenges in their respective industries.

Whether you require Occupational First-Aid Levels 1, 2, and 3 courses, fall protection training, or confined spaces training for entrants and monitors – we’ve got you covered. Contact us now to explore your options and prioritize your employees to improve your brand image!