Fall protection is a critical aspect of workplace safety, especially in industries where employees are exposed to heights and hazardous environments. Proper fall protection training not only helps prevent accidents but also ensures compliance with safety regulations. This comprehensive guide explores the importance of fall protection training, the various systems and equipment available, and case studies highlighting successful implementation.

We will also incorporate important keywords like fall protection courses, confined space training, and first aid training courses to optimize the blog for search engines.

Introduction to Fall Protection Training

Fall protection training is an essential component of workplace safety programs. It equips employees with the knowledge and skills necessary to recognize fall hazards, use fall protection systems correctly, and respond effectively in case of an emergency.

Given the high risk associated with working at heights, fall protection training is not just a regulatory requirement but a moral obligation to ensure the safety and well-being of workers.

Importance of Fall Protection Training

Fall protection training is crucial for several reasons:

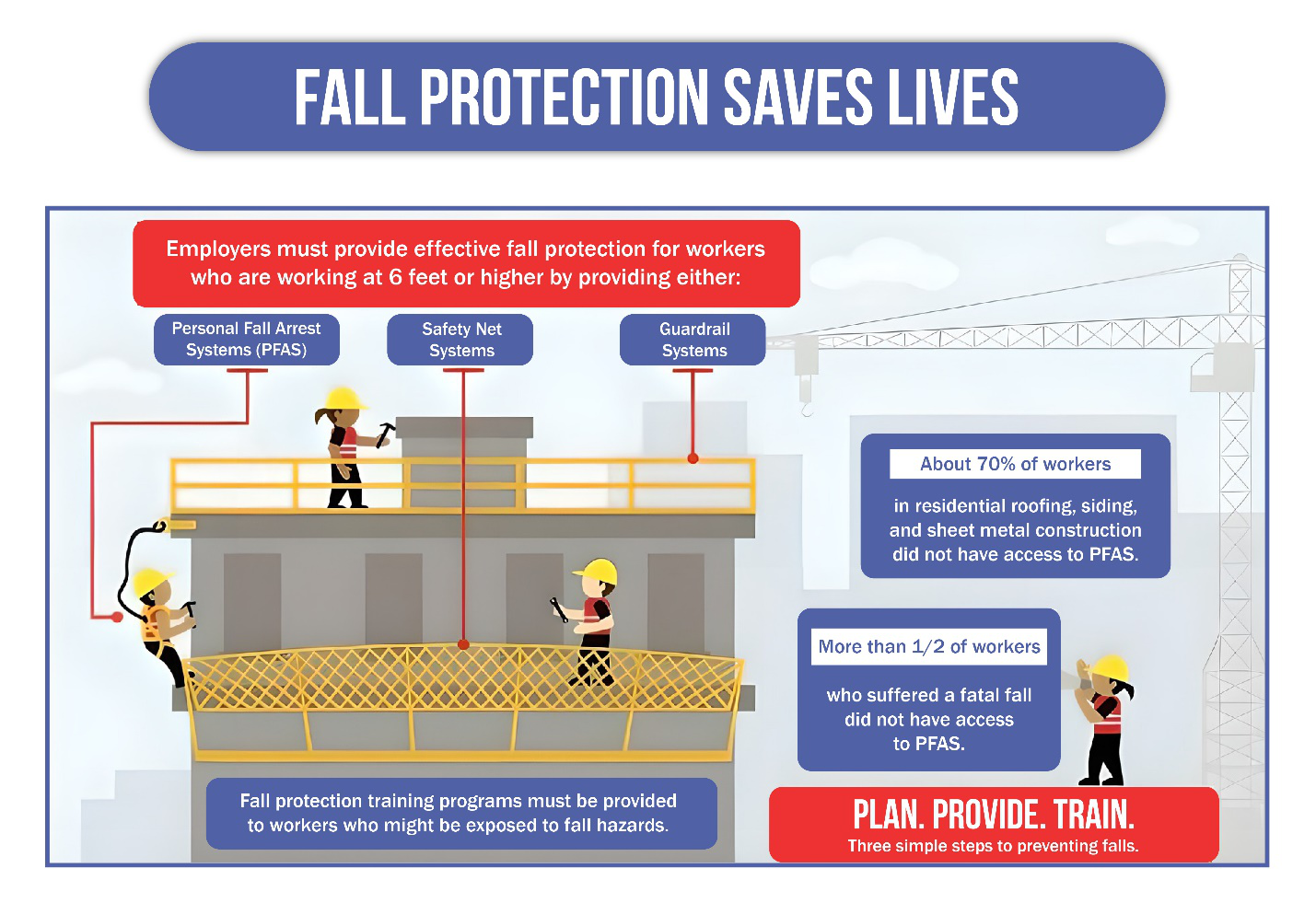

- Preventing Accidents and Injuries: Falls are one of the leading causes of workplace injuries and fatalities. Proper training helps employees understand how to use fall protection equipment correctly, reducing the likelihood of accidents.

- Compliance with Regulations: Regulatory bodies like WorkSafeBCmandate fall protection training for workers exposed to fall hazards. Compliance with these regulations is essential to avoid penalties and ensure workplace safety.

- Enhancing Worker Confidence: Employees trained in fall protection are more confident in their ability to perform tasks safely, leading to increased productivity and morale.

- Reducing Liability: Proper training minimizes the risk of accidents, thereby reducing the potential for costly lawsuits and workers’ compensation claims.

Fall Protection Training Components

A comprehensive fall protection training program typically includes the following components:

- Hazard Recognition: Identifying potential fall hazards in the workplace.

- Equipment Use: Training on the proper use of fall protection equipmentsuch as harnesses, lanyards, and anchor points.

- Emergency Response: Procedures for responding to fall incidents, including rescue techniques.

- Regulatory Requirements: Understanding and complying with relevant safety regulations and standards.

- Practical Exercises: Hands-on training to reinforce theoretical knowledge.

Types of Fall Protection Systems and Equipment

Various fall protection systems and equipment are designed to protect workers from falls. Understanding the different types and their applications is crucial for effective fall protection.

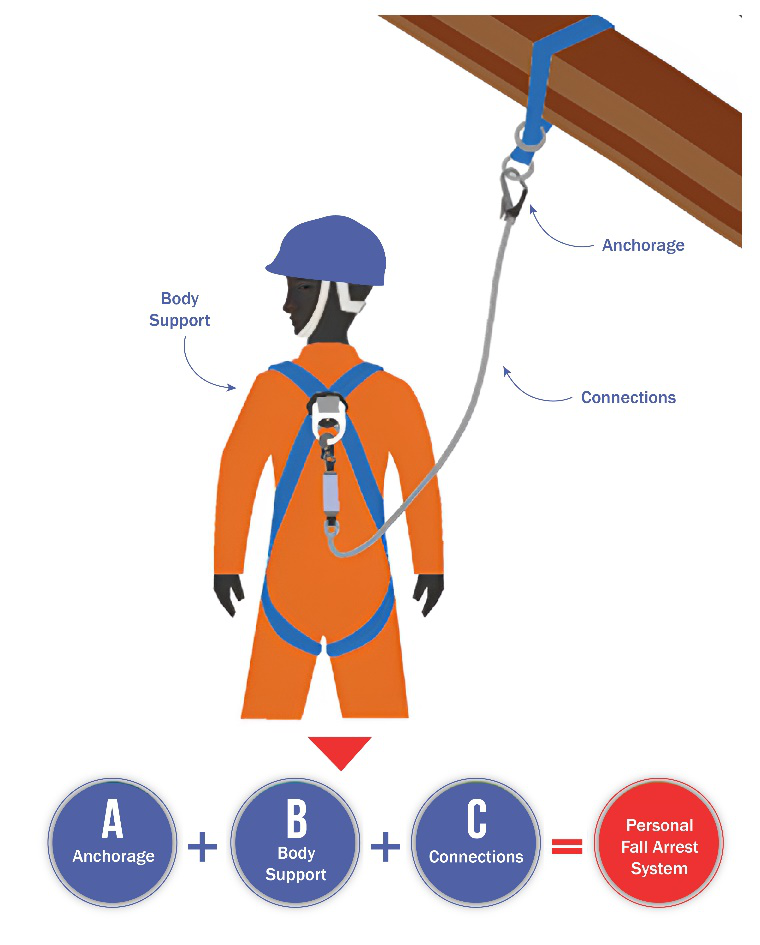

Personal Fall Arrest Systems (PFAS)

Personal Fall Arrest Systems are designed to stop a worker’s fall before they hit a lower surface. PFAS typically include:

- Harnesses: Full-body harnesses distribute the force of a fall across the worker’s body, reducing the risk of injury.

- Lanyards and Lifelines: These components connect the harness to an anchor point, limiting the distance a worker can fall.

- Anchor Points: Secure points where lifelines or lanyards are attached, providing a stable connection.

Guardrail Systems

Guardrail systems are passive fall protection measures that prevent workers from reaching fall hazards. They are typically used on platforms, walkways, and rooftops.

Safety Nets

Safety nets are installed below work areas to catch falling workers and debris. They are commonly used in construction sites and other environments where guardrails and PFAS are impractical.

Fall Restraint Systems

Fall restraint systems prevent workers from reaching fall hazards by limiting their movement. These systems typically include body belts or harnesses connected to anchor points.

Controlled Access Zones

Controlled access zones are designated areas where workers can perform tasks without conventional fall protection systems. These zones require strict access control and monitoring to ensure safety.

Best Practices for Fall Protection

Implementing best practices for fall protection helps create a safer work environment and reduces the risk of accidents.

Conducting Regular Risk Assessments

Regular risk assessments are essential to identify and mitigate fall hazards in the workplace. These assessments should be conducted by trained professionals and updated regularly to reflect changes in the work environment.

Providing Comprehensive Training

Ensuring that all employees receive comprehensive fall protection training is crucial for workplace safety. Training should cover hazard recognition, equipment use, emergency response, and regulatory requirements.

Inspecting Equipment Regularly

Regular inspection of fall protection equipment is essential to ensure it is in good working condition. Damaged or worn equipment should be replaced immediately to prevent accidents.

Implementing a Fall Protection Plan

A fall protection plan outlines the measures and procedures to prevent falls in the workplace. It should include hazard identification, equipment selection, training requirements, and emergency response protocols.

Encouraging a Safety Culture

Promoting a safety culture within the organization encourages employees to prioritize safety and report potential hazards. This culture should be reinforced through regular training, communication, and leadership commitment.

Case Studies: Successful Fall Protection Implementation

Examining real-world examples of successful fall protection implementation provides valuable insights into effective strategies and practices.

Case Study 1: Construction Site Safety

A construction company implemented a comprehensive fall protection program that included regular risk assessments, employee training, and strict equipment inspection protocols. The program significantly reduced the number of fall-related incidents and improved overall workplace safety.

Case Study 2: Manufacturing Plant Safety

A manufacturing plant invested in fall protection training for all employees and installed guardrail systems in high-risk areas. The plant also implemented a fall protection plan and conducted regular safety audits. These measures led to a decrease in workplace accidents and enhanced employee confidence.

Selecting the Right Fall Protection Equipment

Choosing the right fall protection equipment is crucial for ensuring worker safety. Several factors should be considered when selecting equipment:

Understanding the Work Environment

The work environment plays a significant role in determining the appropriate fall protection equipment. For example, different equipment may be required for construction sites, manufacturing plants, and warehouses.

Evaluating Fall Hazards

Identifying and evaluating fall hazards is essential for selecting the right equipment. Factors such as the height of the work area, the presence of sharp edges, and the type of work being performed should be considered.

Considering Worker Comfort

Comfort is an important consideration when selecting fall protection equipment. Comfortable equipment is more likely to be used correctly and consistently by workers.

Ensuring Compliance with Standards

Fall protection equipment should comply with relevant safety standards and regulations. Ensuring compliance helps prevent accidents and avoid penalties from regulatory bodies.

Training on Equipment Use

Providing training on the proper use of fall protection equipment is essential for ensuring its effectiveness. Training should cover equipment inspection, fitting, and use procedures.

Maintaining Fall Protection Equipment

Proper maintenance of fall protection equipment is crucial for ensuring its effectiveness and longevity. Regular maintenance practices include:

Conducting Regular Inspections

Regular inspections help identify and address any damage or wear to fall protection equipment. Inspections should be conducted by trained professionals and documented for reference.

Cleaning and Storing Equipment

Proper cleaning and storage of fall protection equipment help prevent damage and extend its lifespan. Equipment should be cleaned according to the manufacturer’s instructions and stored in a dry, cool environment.

Replacing Damaged Equipment

Damaged or worn equipment should be replaced immediately to ensure worker safety. Regular inspections help identify equipment that needs replacement.

Keeping Records

Maintaining records of equipment inspections, maintenance, and replacement is essential for ensuring compliance with safety standards and regulations.

Training and Certification Opportunities

Proper training and certification play a crucial role in enhancing fall protection awareness and preparedness in the workplace. Metro Safety Training offers a variety of training programs to help individuals acquire the knowledge and skills necessary to respond effectively to fall hazards.

Fall Protection Training

Metro Safety Training provides comprehensive fall protection training programs that cover hazard recognition, equipment use, emergency response, and regulatory requirements. These programs help ensure compliance with safety standards and enhance worker confidence.

Ooccupational First Aid Levels 1, 2, and 3

Metro Safety Training offers Occupational First Aid Levels 1, 2, and 3 courses to help individuals acquire advanced first aid skills and certification. These courses are essential for workers in high-risk environments.

Occupational First Aid Level 3 Pro Renewal

For those who need to renew their Occupational First Aid Level 3 certification, Metro Safety Training offers pro-renewal courses in Surrey. These courses help ensure that individuals maintain their certification and stay up-to-date with the latest first-aid techniques.

Confined Space Safety Training

Metro Safety Training also provides confined space safety training, helping individuals recognize and respond to hazards associated with confined spaces. This training is essential for workers in industries where confined space entry is required.

Contact Metro Safety Training today to explore our comprehensive fall protection training programs and certification opportunities. Ensure the safety and well-being of your employees with our expert training and support. Call us now.