Proper gear is not just a matter of comfort but a critical component of safety. From personal protective equipment (PPE) to atmospheric monitors, each piece of gear plays a vital role in safeguarding workers from the numerous hazards inherent to confined spaces.

In this comprehensive guide, we’ll delve into the intricacies of selecting and using confined space safety equipment, ensuring that workers are well-prepared and protected in their challenging work environments.

Understanding Confined Space Hazards

Before diving into the specifics of gear selection, it’s essential to first understand the hazards that workers may encounter in confined spaces. Atmospheric hazards, engulfment risks, limited visibility, and confined space configurations are just a few examples of the dangers workers may face. By recognizing these hazards, employers and workers can make informed decisions when selecting gear that provides adequate protection.

Check out our confined space safety training courses in Surrey now.

Personal Protective Equipment (PPE)

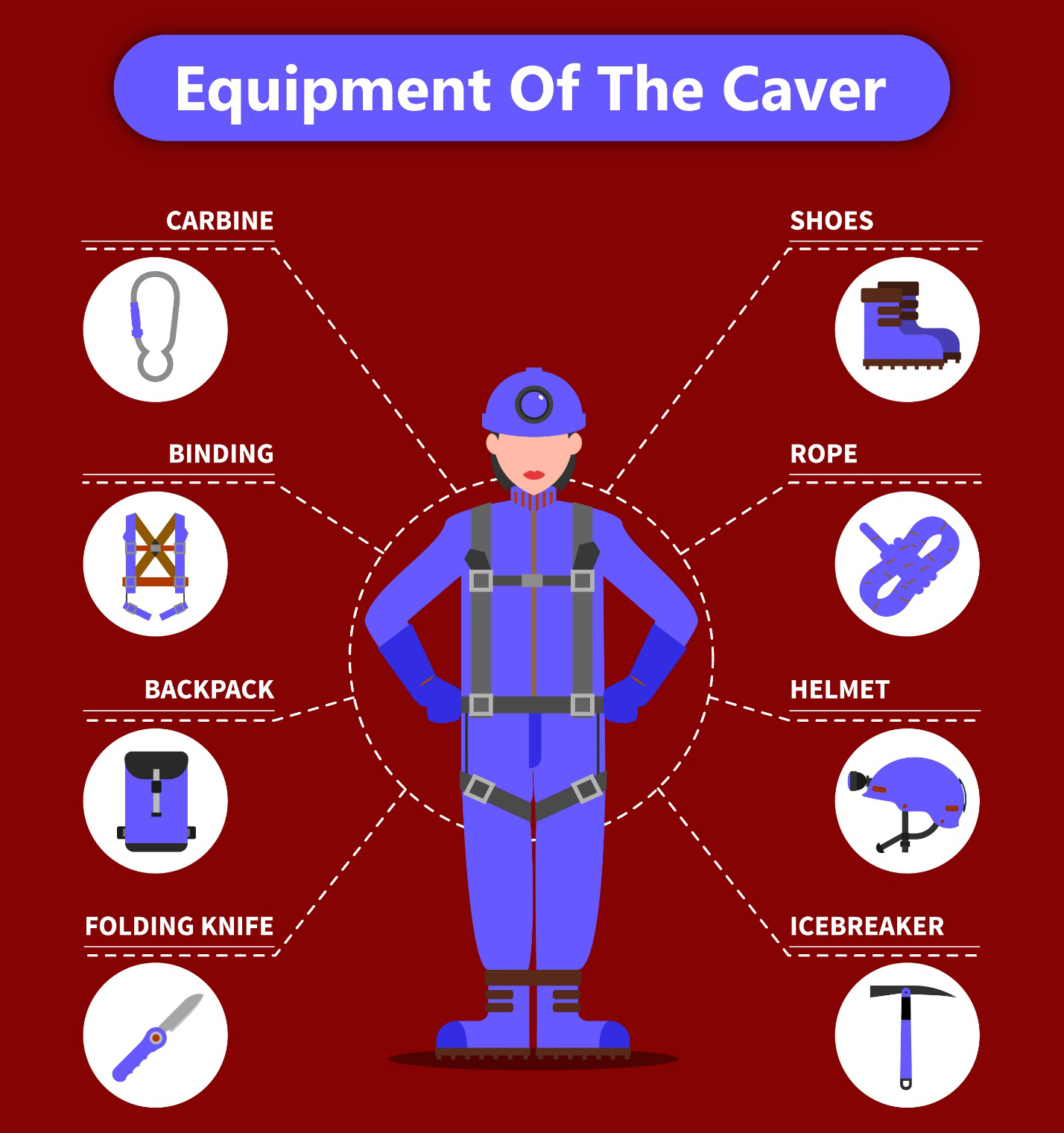

Personal protective equipment is the frontline defense against confined space hazards. This section will explore the various types of PPE commonly used in confined space work, including respiratory protection, protective clothing, gloves, eye and face protection, and hearing protection. We’ll discuss the specific hazards each type of PPE addresses and guide you on selecting the appropriate gear for different confined space environments.

Personal protective equipment is the first line of defense against confined space safety hazards. This includes:

Respiratory Protection: Respirators are vital for protecting workers from airborne contaminants, gases, and vapors commonly found in confined spaces. They come in various forms, including disposable masks, half-face respirators, and full-face respirators, each offering different levels of protection.

Protective Clothing: Specialized clothing such as coveralls, chemical-resistant suits, and flame-retardant garments shield workers from physical and chemical hazards present in confined spaces.

Eye and Face Protection: Safety goggles, face shields, and welding helmets protect workers’ eyes and faces from flying debris, splashing liquids, and harmful chemicals.

Hand and Foot Protection: Gloves and boots designed for confined space work protect against cuts, punctures, chemical exposure, and electrical hazards.

Application: PPE is essential for workers entering confined spaces where atmospheric hazards, physical hazards, or hazardous substances pose a risk to their health and safety.

Benefits: Properly selected and worn PPE minimizes the risk of injury or illness, providing a barrier between workers and potential hazards. It enhances worker safety, confidence, and productivity, ensuring a safer work environment overall.

Respiratory Protection

Given the prevalence of atmospheric hazards in confined spaces, respiratory protection is of paramount importance. We’ll delve into the different types of respiratory protection available, such as air-purifying respirators, supplied air respirators, and self-contained breathing apparatus (SCBA). Additionally, we’ll discuss fit testing, maintenance procedures, and proper storage practices to ensure the effectiveness of respiratory protection gear.

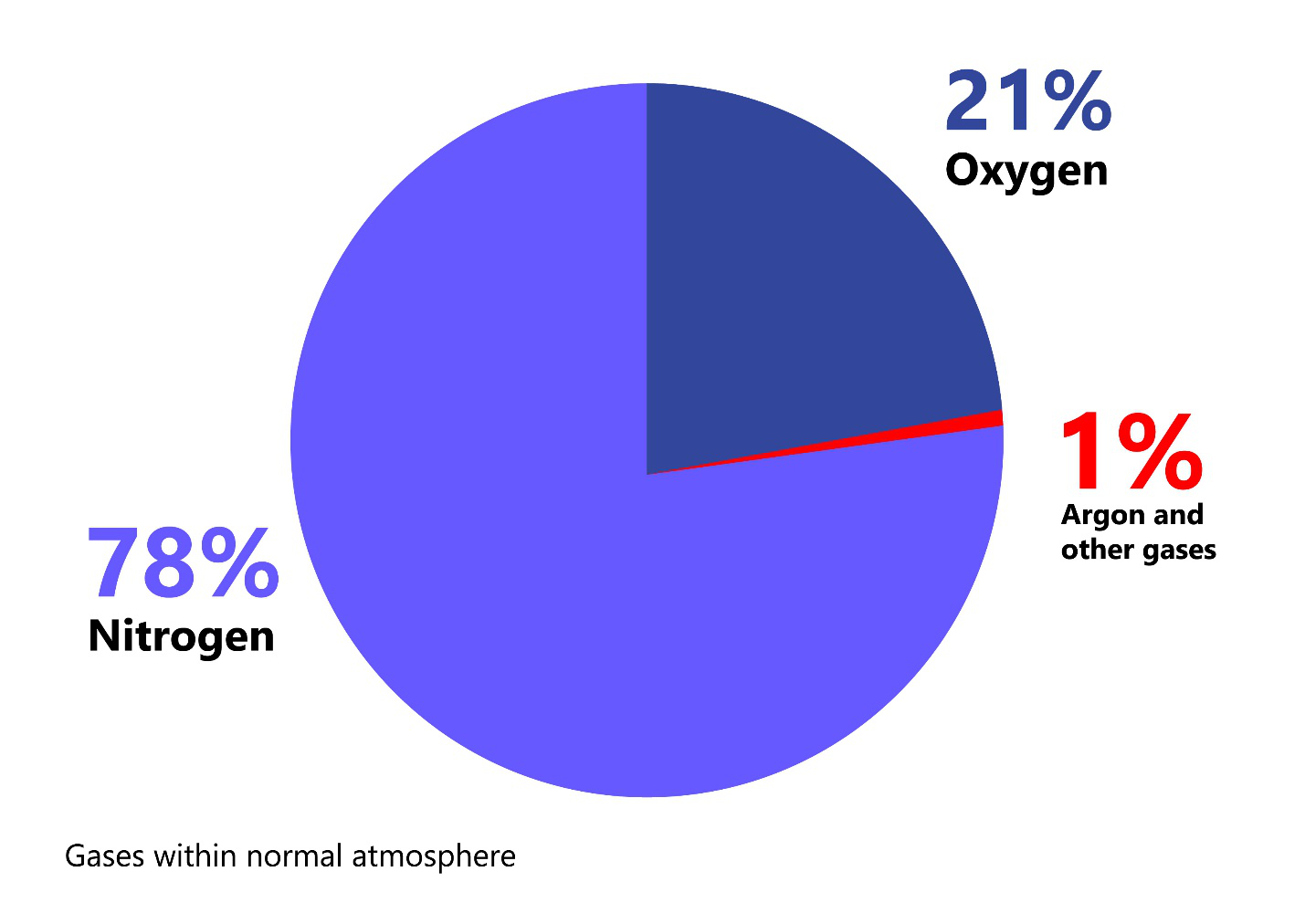

Atmospheric monitors are critical for detecting and monitoring hazardous gases, vapors, and oxygen levels in confined spaces. These include:

Single-gas detectors: These monitors detect specific gases such as carbon monoxide (CO), hydrogen sulfide (H2S), or oxygen (O2) and provide audible and visual alarms when concentrations exceed safe levels.

Multi-Gas Detectors: These monitors can detect multiple gases simultaneously, offering comprehensive protection in complex confined space environments.

Portable Gas Detectors: Compact and lightweight, these monitors are designed for easy transport and use in confined spaces with limited access.

Application: Atmospheric monitors are used before and during confined space entry to assess air quality, identify potential hazards, and ensure safe working conditions for entrants.

Benefits: By continuously monitoring atmospheric conditions, these devices provide early warning of potential hazards, allowing workers to take corrective action or evacuate the area promptly. This helps prevent accidents, injuries, and fatalities associated with exposure to toxic gases or oxygen deficiency.

Equip your workers with occupational first aid level 1, level 2, and level 3 training programs in Vancouver for extended safety and well-being.

Protective Clothing

Protective clothing serves as a barrier against physical and chemical hazards in confined spaces. They include flame resistance, chemical resistance, and ergonomic design. Proper donning and doffing techniques, as well as care and maintenance guidelines, will also be covered to prolong the lifespan of protective clothing.

Effective Communication

Effective communication is essential for coordinating activities and ensuring the safety of workers in confined spaces. Communication devices include

Two-Way Radios: These portable devices allow workers to communicate with each other and with attendants stationed outside the confined space, providing real-time updates on work activities, hazards, and emergencies.

Hand Signals: Simple hand signals are often used for communication in environments where noise or distance limits verbal communication. Standardized hand signals ensure clear and consistent communication between workers.

Application: Communication devices facilitate effective communication between entrants, attendants, and monitors during confined space entry and work activities, enhancing coordination and safety.

Benefits: Clear and reliable communication helps prevent misunderstandings, reduces the risk of accidents, and enables timely response to emergencies. It fosters teamwork and cooperation among workers, improving overall safety and productivity in confined spaces.

Rescue and Retrieval Equipment

In the event of an emergency, having the right rescue and retrieval equipment can mean the difference between life and death. This equipment includes:

Tripods and Winches: These devices provide a secure anchor point for lowering and raising workers into and out of confined spaces safely.

Rescue Harnesses and Lifelines: Designed to support and protect workers during rescue operations, these harnesses feature attachment points for lifelines, hooks, and other rescue equipment.

Rescue Stretchers and Splints: Used for extricating injured or incapacitated workers from confined spaces, these devices provide support and immobilization during rescue operations.

Application: Rescue and retrieval equipment are essential for facilitating the safe extraction of workers in the event of an emergency, such as injury, illness, or entrapment, in confined spaces.

Benefits: By ensuring prompt and efficient rescue operations, this equipment minimizes the risk of further injury or harm to workers in confined spaces. It provides peace of mind to workers, knowing that help is readily available in case of an emergency.

Hands, Feet, and Vision Protection

Hands and feet are vulnerable to injuries in confined spaces, making the selection of appropriate gloves and footwear essential. The various types of gloves and footwear designed for confined space work include cut-resistant gloves, chemical-resistant gloves, and slip-resistant boots. Proper sizing, material compatibility, and inspection procedures will also be addressed to minimize the risk of hand and foot injuries.

Confined spaces safety is often jeopardised by low light conditions, making adequate lighting essential for visibility and safety. Lighting equipment includes:

Portable Work Lights: These lights provide illumination in confined spaces where natural or ambient lighting is insufficient, enabling workers to see clearly and perform tasks safely.

Explosion-Proof Lights: Designed for use in hazardous environments, these lights are intrinsically safe and do not pose a risk of igniting flammable gases or vapors.

Handheld Flashlights: Compact and versatile, handheld flashlights are essential for navigating dark or cramped spaces and conducting inspections or repairs.

Application: Lighting equipment ensures adequate visibility in confined spaces, reducing the risk of trips, falls, and other accidents caused by poor visibility.

Benefits: Proper lighting enhances worker safety and productivity, enabling them to identify hazards, perform tasks accurately, and respond effectively to emergencies. It reduces the risk of accidents and injuries associated with working in confined spaces with limited visibility.

Care and Maintenance of Equipment

Proper care and maintenance are vital aspects of ensuring the longevity and effectiveness of confined space gear. By following best practices for inspecting, cleaning, and storing personal protective equipment (PPE) and atmospheric monitors, workers can prevent damage and deterioration, ultimately enhancing their safety in confined spaces.

Inspection: Regular inspections of PPE and atmospheric monitors are essential for identifying any signs of wear, damage, or malfunction. Workers should visually inspect their gear before each use, paying close attention to straps, seals, lenses, and sensors. Any defects or abnormalities should be reported immediately and addressed by a qualified technician.

Cleaning: Keeping PPE and atmospheric monitors clean is crucial for maintaining their functionality and reliability. Workers should follow manufacturer guidelines for cleaning and disinfecting their gear, using appropriate cleaning agents and methods to remove dirt, debris, and contaminants. Regular cleaning helps prevent the buildup of residues and ensures that equipment remains in optimal working condition.

Storage: Proper storage is key to protecting PPE and atmospheric monitors from environmental factors that could cause damage or degradation. Gear should be stored in a clean, dry, and well-ventilated area away from direct sunlight, extreme temperatures, and moisture. When not in use, equipment should be stored in its original packaging or dedicated storage containers to prevent exposure to dust, dirt, and other contaminants.

At Metro Safety Training, we offer comprehensive training programs designed to equip workers with the knowledge and skills they need to work safely and confidently in confined spaces.

Gear Selection and Inspection: Our confined space safety training programs in Surrey cover the proper selection and inspection of PPE and atmospheric monitors, helping workers identify the right gear for the job and ensure that it is in good working condition before use.

Hazard Recognition: Recognizing potential hazards is a critical aspect of confined space safety. Our training includes instruction on identifying common hazards such as atmospheric dangers, physical hazards, and hazardous substances, as well as strategies for mitigating these risks.