When it comes to working at heights, having the right fall protection equipment isn’t just a matter of compliance—it’s a critical component of workplace safety. Every piece of equipment, from harnesses to lanyards and anchors, must meet specific strength ratings to ensure they can effectively arrest a fall without failure. This blog delves into the essentials of fall protection training equipment, emphasizing the importance of selecting the right gear and using it correctly to safeguard your life.

Importance of Strength Ratings

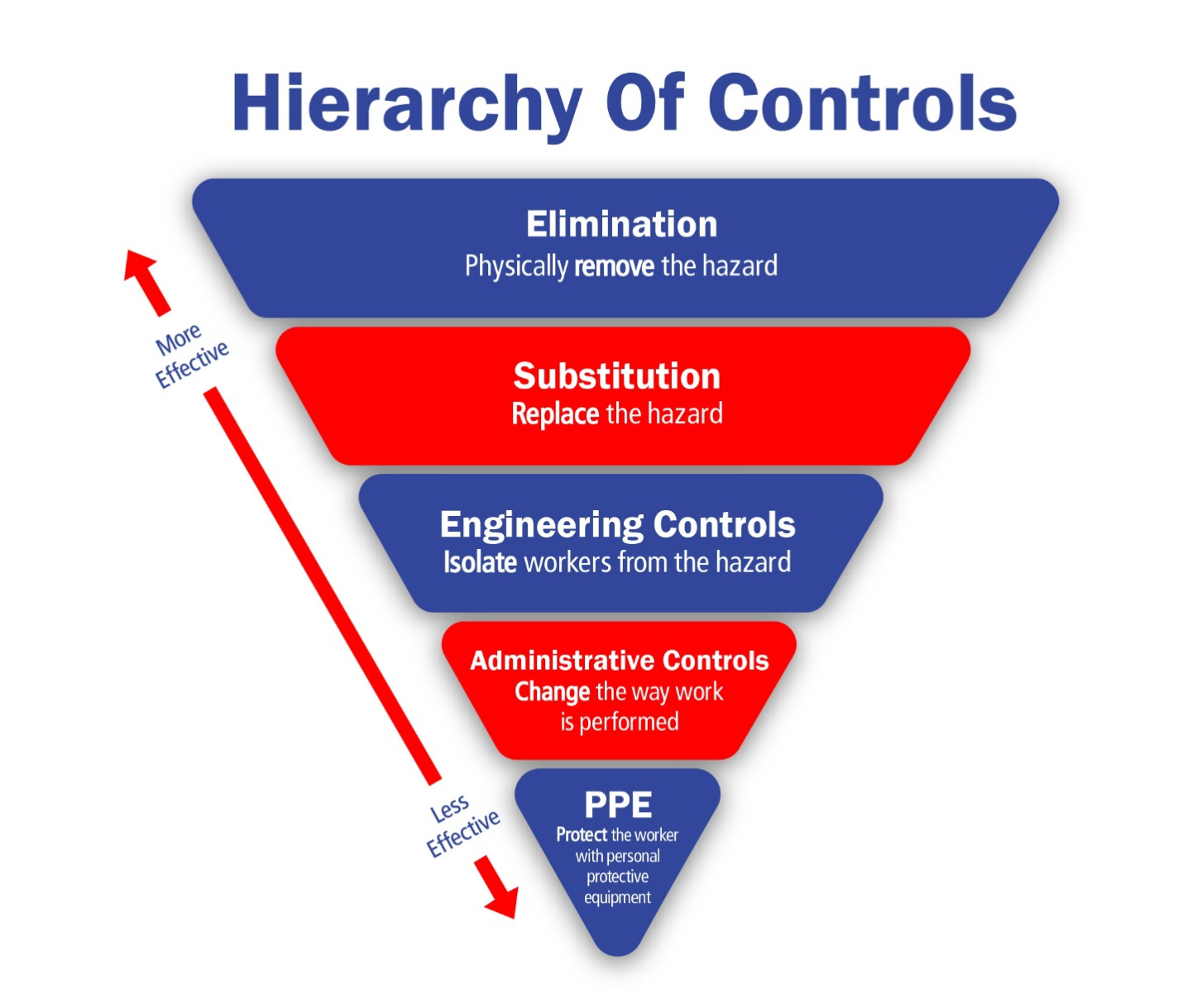

In the realm of fall protection safety plans, understanding and adhering to equipment strength ratings is not merely a regulatory requirement—it is a fundamental aspect of ensuring safety when working at heights. These ratings are crucial indicators of the capability of fall protection gear to withstand the forces generated during a fall, thereby preventing serious injuries or fatalities.

Here’s a deeper look at why strength ratings are vital and how they should influence the selection and use of fall protection equipment.

1. Defining Strength Ratings

Strength ratings, often referred to as load capacity or maximum arresting force, are determined through rigorous testing standards set by safety organizations and manufacturers. These ratings define the maximum weight and force that equipment such as harnesses, lanyards, and anchors can safely support without failure. For example, a typical fall protection trainingharness might be rated to support up to 5,000 pounds of force, a standard derived from safety regulations that account for the dynamic forces experienced during a fall.

2. Role of Strength Ratings in Equipment Selection

Selecting the correct fall protection training equipment based on strength ratings is essential for several reasons.

a) Worker Safety

The primary purpose of strength ratings is to ensure that equipment can safely arrest a fall without breaking. This is critical for preventing fatalities and severe injuries in the event of a fall.

b) Compliance with Safety Standards

Using equipment that meets or exceeds required strength ratings is mandatory for compliance with safety standards and regulations. Non-compliance can lead to serious legal consequences.

c) Adaptation to Various Work Conditions

Different job tasks and environments may exert different forces on fall protection equipment. Understanding and choosing equipment with the appropriate strength ratings for specific conditions is crucial.

3. Enhancing Safety Through Appropriate Training

Understanding how to interpret and apply strength ratings in practical scenarios is key, and this knowledge is imparted through comprehensive fall protection training. Such training courses not only cover the basics of equipment selection but also delve into how to correctly deploy and use the equipment based on its rated capacities.

For workers and safety managers in Surrey, engaging in level 2 first aid training in Surrey or first aid training courses in Surrey can complement this knowledge, equipping them to handle any injuries that might occur despite preventive measures.

Selecting the Right Equipment

Selecting the right fall protection equipment is crucial for ensuring safety when working at heights. The process involves understanding the specific needs of the work environment and the tasks to be performed, as well as the physical requirements and comfort of the worker.

Here’s a deeper look into how to choose the appropriate gear for optimal safety and efficiency, integrating critical considerations and key training aspects from a thoroughfall protection safety plan.

1. Understanding Work Requirements

The first step in selecting the right equipment is to assess the specific conditions and requirements of the work site. Consider the height at which workers will be operating, the nature of the work (static vs. dynamic), potential hazards, and environmental conditions. For instance, tasks that involve welding at heights will require harnesses and lanyards that are resistant to high temperatures and sparks.

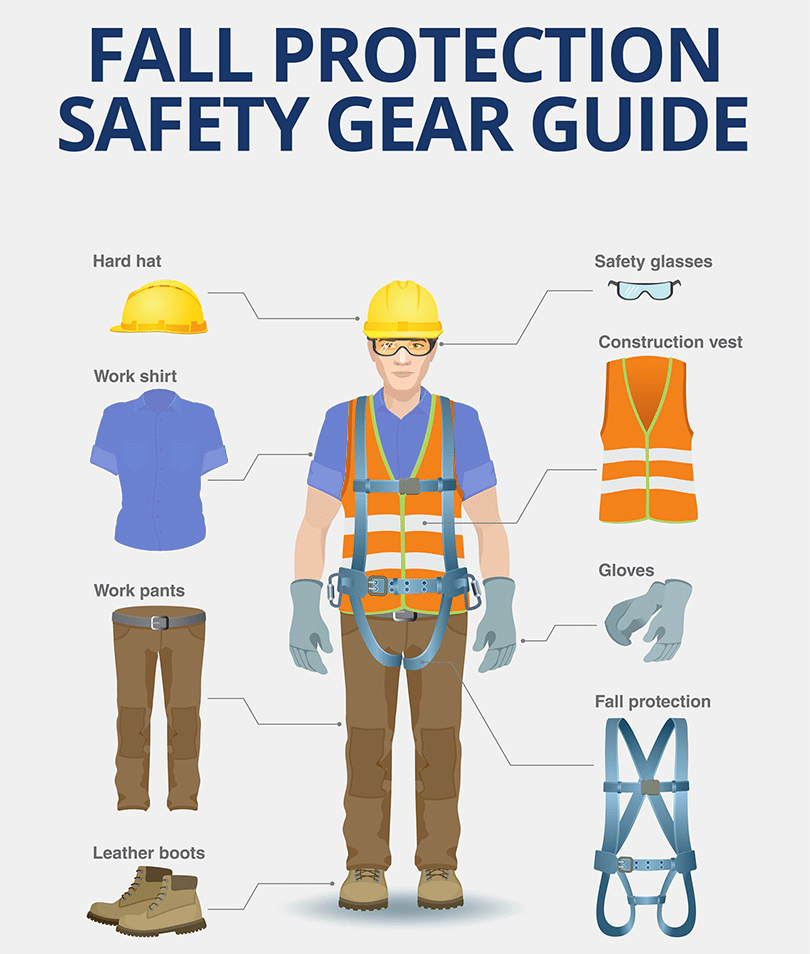

a) Understand Harness Requirements

Making sure a harness is the cornerstone of fall protection equipment is important. But you must also make sure a harness fits snugly but comfortably, allowing for full range of motion. Adjustable chest, shoulder, and leg straps help achieve a good fit.Depending on the task, features such as padded belts for tool carrying, quick-connect buckles, or fire-resistant materials might be necessary, too.

b) Check Weight Capacity and Ratings

Ensure the harness can support the weight of the worker along with any tools and equipment they will carry. Harnesses are typically tested forfall protection training standards but always verify that they meet or exceed these requirements.

c) Lanyard and Lifeline Selection

Choosing the right lanyard or lifeline involves several considerations. The lanyard length should be appropriate for the height at which the work is performed, including considerations for the potential fall distance and minimizing swing falls. Furthermore, lanyards with shock-absorbing properties and anchor points help reduce the forces exerted on the worker’s body during a fall, which is crucial for preventing injuries. Lastly, depending on the work environment, materials resistant to abrasion, heat, or chemicals may be required.

d) Assess Load Capacity

Anchors must be capable of supporting at least 5,000 pounds per worker attached or must be designed with a safety factor of two under the supervision of a qualified engineer as per fall protection inspection trainingguidelines. If you need something versatile, mobile and reusable anchors offer flexibility for tasks that require movement across large areas or at different sites.

Understanding Safe Use Practices

When it comes to fall protection, the proper use of equipment is just as crucial as having the right gear. Understanding and implementing safe use practices are essential for ensuring that the equipment provides the maximum level of safety during operations at height. These practices are reinforced through specialized fall protection courses.

1. Comprehensive Training

The foundation of safe use practices is comprehensive training that covers all aspects of fall protection equipment. Workers need to be familiar with each piece of gear they will use. Training should include hands-on demonstrations on how to properly don and adjust harnesses to ensure a correct fit, which is vital for the equipment to function correctly in the event of a fall.

Fall protection coursesoften include modules on how to securely attach lanyards and choose appropriate anchor points that can sustain the forces of a fall. These training programs can be very advanced and can give staff a holistic overview of their workplace safety needs, allowing them to view and interact with it safely.

2. Regular Equipment Checks

Before any use of fall protection equipment, it is imperative to perform thorough inspections. Workers should be trained to look for signs of wear, tear, and damage, such as frayed straps, cracked buckles, and weak connectors. Any equipment that shows signs of potential failure should be immediately removed from service.

This routine is a key part of fall protection inspection training, ensuring that all equipment is in optimal condition to provide reliable protection.

3. Adherence to Manufacturer’s Instructions

Following the manufacturer’s instructions for the use and maintenance of fall protection equipment is crucial. These guidelines are designed to ensure that the equipment performs as tested and certified. Instructions often include specifics on how to clean and store the equipment properly to avoid damage and degradation, thereby extending its useful life.

4. Simulating Emergency Scenarios

Part of understanding safe use practices involves preparing for potential fall scenarios through simulation and drills. This hands-on approach helps workers internalize their training and react more effectively in real situations.

Confined space trainingalso contributes to this preparedness, as it often includes emergency response techniques in challenging environments.

5. Routine Inspection and Maintenance

Regular inspection is key to ensuring that fall protection equipment remains in safe working condition. This involves checking for any signs of wear, tear, or damage before and after use.

Look for frayed edges, cracked buckles, or signs of severe wear in straps and ropes. Regular fall protection inspection training can teach you how to perform these checks systematically and document them.

6. Replacement and Disposal

Even the best fall protection gear has a lifespan. It’s crucial to know when to retire and replace equipment. Most manufacturers recommend inspection intervals and replacement timelines. Follow these guidelines diligently, and always replace any equipment involved in a fall immediately, as its integrity could be compromised.

Get Thorough Training from Metro Safety

Ensuring the safety of workers operating at heights is critical, and it begins with comprehensive fall protection and meticulous adherence to safety practices. Metro Safety Training excels in providing top-tier fall protection training that thoroughly prepares workers to safely navigate the risks associated with elevated work environments.

Our expert-led courses, including confined space training and level 2 first aid training in Surrey, are designed not only to meet but exceed industry standards, offering hands-on experience and practical knowledge that workers can immediately apply in the field. By choosing Metro Safety Training, you’re partnering with a leader in safety education that prioritizes the well-being of your workforce and the integrity of your operations.

Visit Metro Safety Training today to schedule your sessions and build a robust safety culture that stands the test of time.