Among the many factors that contribute to workplace safety, forklift operator training stands out as a critical element. When operators are well-trained, not only are accidents involving forklifts reduced, but the overall safety culture of the workplace is also significantly enhanced.

This blog explores how advanced forklift operator training interrelates with workplace safety culture and the broader impact on safety performance.

Understanding the Role of Forklift Operator Training

Forklifts are indispensable in many industries, particularly in warehouses, manufacturing plants, and construction sites. However, operating these machines requires a high level of skill and awareness, as improper use can lead to severe accidents. Forklift operator training is designed to equip operators with the necessary skills and knowledge to handle these vehicles safely and efficiently.

The Impact of Forklift Operator Training on Workplace Safety Culture

Workplace safety culture refers to the collective mindset, attitudes, and practices regarding safety within an organization. A strong safety culture is characterized by a commitment to safety at all levels, from top management to front-line workers. Forklift operator training plays a significant role in cultivating this culture.

Safety Awareness

When employees undergo comprehensive forklift operator training, they become more aware of safety protocols and the importance of adhering to them. This awareness naturally extends to other aspects of their work, fostering a proactive approach to safety. For example, an operator who understands the importance of proper load balancing on a forklift is likely to be more conscientious about following safety guidelines in other areas as well.

Team Motivation

Well-trained operators serve as role models for their peers, encouraging a workplace environment where safety is prioritized. This influence can lead to a ripple effect, where safety practices become ingrained in the daily routines of all employees, thereby strengthening the overall safety culture.

Enhancing Safety Through Advanced Forklift Operator Training

Advanced forklift operator training is essential in high-risk industries. It equips operators with specialized skills that are necessary for handling unique challenges, such as navigating confined spaces or operating in areas with high pedestrian traffic. This type of training often includes simulated exercises, allowing operators to practice in a controlled environment before applying their skills in the real world.

By addressing the specific risks associated with forklift operations, advanced training helps reduce the likelihood of accidents. This reduction in accidents not only protects workers but also minimizes downtime and the associated costs of workplace injuries.

Companies that invest in advanced training demonstrate a commitment to safety that goes beyond mere compliance with regulations, promoting a culture where safety is seen as a core value.

The Integration of Forklift Training with Other Safety Programs

To maximize the effectiveness of forklift operator training, it should be integrated with other workplace safety programs. For instance, incorporating elements of fall protection safety plans and confined space safety plans into forklift training can provide operators with a more comprehensive understanding of the hazards they may encounter.

Training that combines multiple safety disciplines ensures that operators are prepared to handle a variety of situations. For example, understanding the principles of fall protection safety plans is crucial for operators who work in environments where falls from heights are a risk.

Similarly, knowledge of confined space safety is essential for operators who may need to maneuver forklifts in tight or restricted areas.

This multidisciplinary approach to safety training reinforces the idea that safety is a holistic concern that touches all aspects of the workplace. It encourages employees to think critically about the safety implications of their actions and to apply their training across different scenarios.

The Role of First Aid Training in Supporting a Safe Workplace

While forklift operator training is crucial, it is just one part of a broader safety strategy. First aid training, including basic first aid (OFA Level 1), intermediate first aid training, and Emergency First Aid (EFA)

with CPR/AED Level C plays an equally important role in ensuring that workers are prepared to respond to accidents and injuries.

In the event of a forklift-related incident, the ability to administer first aid quickly and effectively can mean the difference between a minor injury and a life-threatening situation. First aid training equips workers with the skills to provide immediate care while waiting for professional medical assistance to arrive. This prompt response can significantly reduce the severity of injuries and improve the chances of a full recovery.

Integrating first aid training courses in Surrey with forklift training creates a comprehensive safety program that addresses both the prevention and management of workplace injuries. Employees who are trained in both areas are better equipped to handle emergencies, making the workplace safer for everyone.

Forklift Operation Hazards

Operating a forklift comes with inherent risks that, if not properly managed, can lead to serious accidents and injuries. Understanding these hazards is crucial for maintaining a safe workplace.

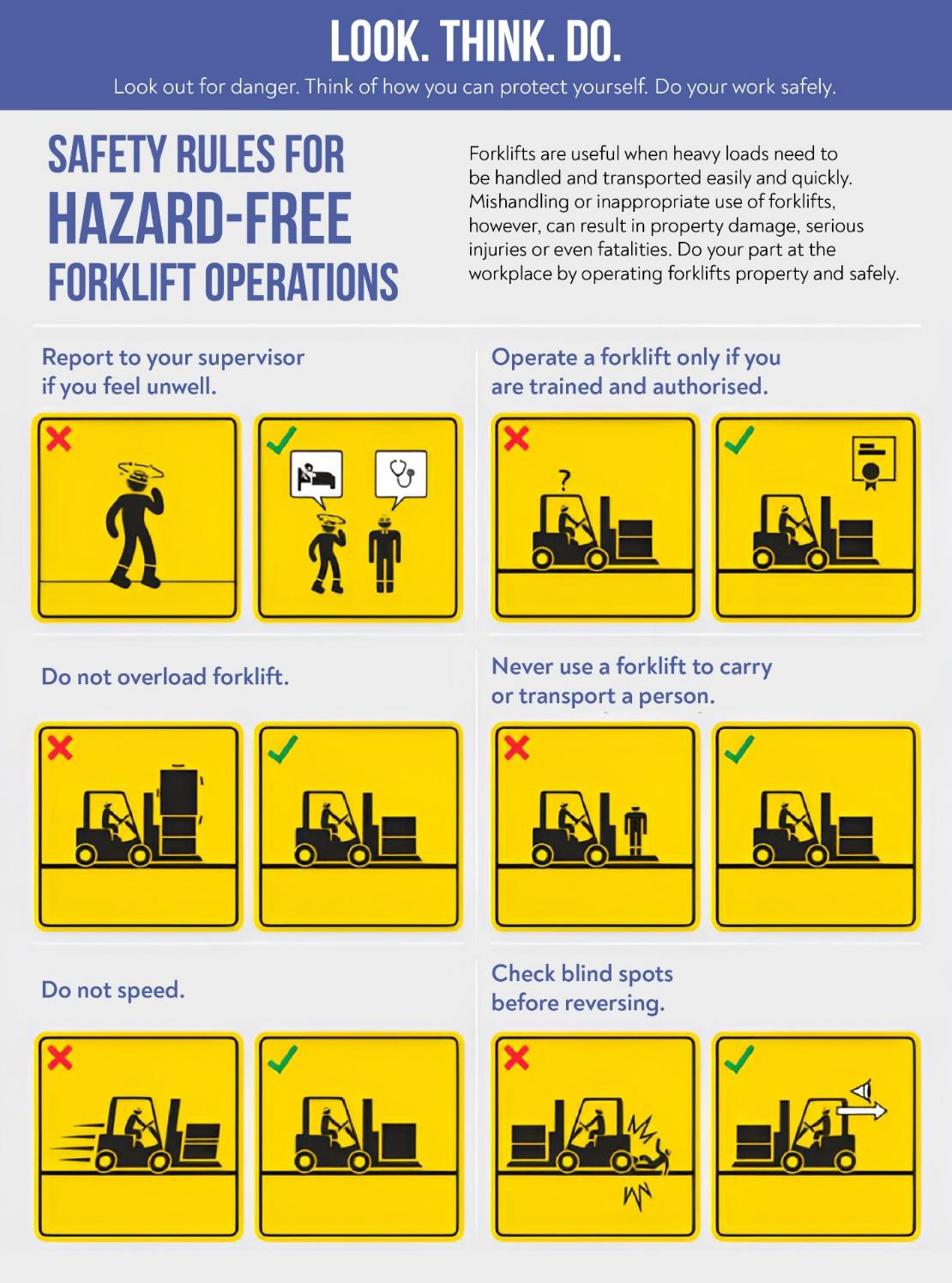

- Tip-Overs:One of the most dangerous risks in forklift operation is the potential for the vehicle to tip over. Tip-overs can cause significant harm to the operator and anyone nearby.

- Collisions:In busy work environments, forklifts are at risk of colliding with other vehicles, structures, or even pedestrians. Collisions can result in severe property damage and injuries.

- Falling Loads:When loads are not secured correctly or the forklift is overloaded, there’s a risk that these loads may fall. Falling loads are especially dangerous and can lead to serious injuries, particularly if they involve heavy or hazardous materials.

- Pedestrian Safety Risks:In workplaces where forklifts and pedestrians operate in the same areas, the likelihood of accidents increases. Pedestrians may be unaware of a forklift’s presence, or operators might not see them due to blind spots.

- Mechanical Failures:Forklifts that are not routinely maintained may experience mechanical issues such as brake failures, steering problems, or hydraulic malfunctions.

- Lack of Training:A significant factor in many forklift accidents is inadequate training. Operators who aren’t thoroughly trained in safe practices, load management, and hazard identification are more likely to make mistakes that could result in serious incidents.

Prevention: Developing a Comprehensive Forklift Safety Strategy

To truly enhance workplace safety, organizations must develop a comprehensive forklift safety strategy that goes beyond operator training. This strategy should include regular safety audits, ongoing training and refresher courses, and a commitment to maintaining equipment in good working condition.

Regular Monitoring

Regular safety audits help identify potential hazards before they lead to accidents. These audits should assess not only the condition of the forklifts but also the effectiveness of the training programs.

By continually evaluating and improving safety practices, companies can ensure that their safety culture remains strong and responsive to new challenges.

Continuous Improvement

Ongoing training is also essential. As technology and industry standards evolve, so too must the skills of forklift operators.

Offering regular refresher courses and advanced training opportunities keeps operators up-to-date with the latest best practices and safety protocols. This ongoing education reinforces the importance of safety and helps maintain high standards across the organization.

Equipment Upkeep

Maintaining equipment is a critical component of any forklift safety strategy. Even the most skilled operators can be put at risk if they are using poorly maintained machinery.

Regular inspections and timely repairs ensure that forklifts are in safe working order, reducing the likelihood of mechanical failures that could lead to accidents.

The Benefits of a Strong Safety Culture

The benefits of a strong workplace safety culture extend beyond accident prevention. Companies that prioritize safety tend to have higher employee morale, lower turnover rates, and increased productivity. When workers feel safe and valued, they are more likely to be engaged and committed to their jobs.

A strong safety culture can enhance a company’s reputation. Businesses that are known for their commitment to safety are more likely to attract top talent and retain customers who value responsible practices. In competitive industries, this reputation can be a significant advantage, helping the company stand out as a leader in both safety and operational excellence.

At Metro Safety Training, we understand the importance of advanced safety training. Our courses are designed to provide the knowledge and skills needed to create a safer, more efficient workplace. Whether you’re looking to improve your forklift operations, develop a fall protection safety plan, or provide first aid training, we have the expertise to help you succeed.

Take the next step in building a safer workplace. Contact Metro Safety Training today to learn more about our comprehensive safety training programs and how we can support your commitment to safety.