Confined spaces present unique challenges and hazards that require specialized safety techniques to mitigate risks effectively. From atmospheric testing to ventilation and lockout procedures, mastering confined space safety is essential for protecting workers and preventing accidents.

In this comprehensive guide, we’ll explore key strategies and training methods for ensuring safety in confined spaces, covering both classroom learning and hands-on skills development.

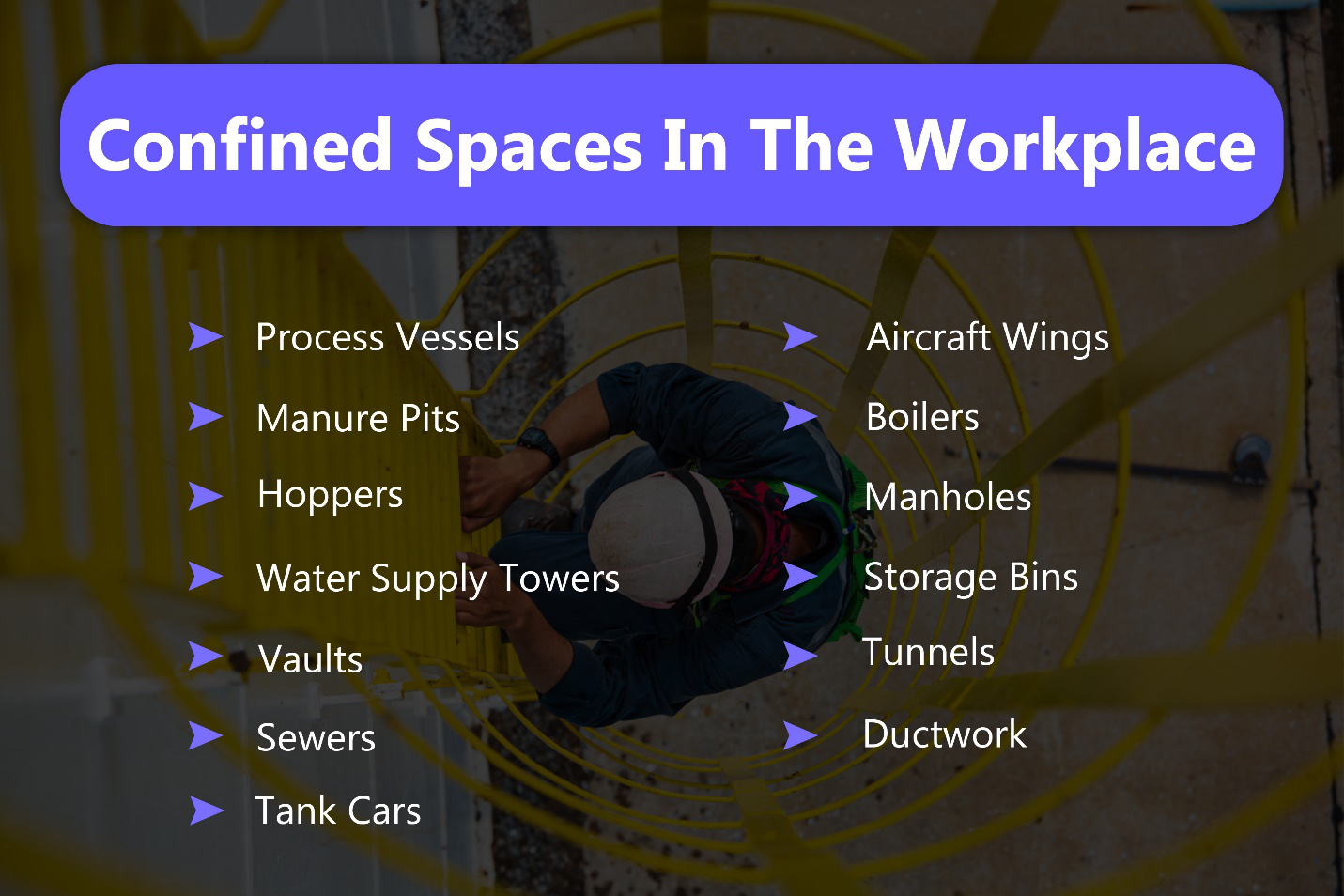

Understanding Confined Spaces

Confined spaces are areas with limited access and egress, making them potentially hazardous for workers. Common examples include storage tanks, silos, sewers, and tunnels. These spaces often have restricted entry points and may contain hazards such as low oxygen levels, toxic gases, or physical obstacles. Understanding the characteristics of confined spaces is crucial for identifying potential risks and implementing safety measures to protect workers.

Hazards Associated with Working in Confined Spaces

Working in confined spaces presents a myriad of hazards that can pose significant risks to the health and safety of workers. Understanding these hazards is crucial for implementing effective control measures and ensuring the well-being of employees. Below are some common hazards associated with confined space work:

Atmospheric Hazards: Confined spaces often have limited ventilation, leading to the accumulation of hazardous gases, vapors, or fumes. These atmospheric hazards can include oxygen deficiency, which increases the risk of asphyxiation, as well as the presence of toxic gases such as carbon monoxide, hydrogen sulfide, or methane, which can cause respiratory problems or even death.

Engulfment: Many confined spaces contain materials such as liquids, granular substances, or flowing solids that pose a risk of engulfment. If a worker becomes trapped or submerged in these materials, they may suffocate or suffer crush injuries, leading to serious or fatal consequences.

Physical Hazards: Confined spaces often have limited space for movement and may contain obstacles, sharp edges, or protruding objects that pose physical hazards to workers. Inadequate lighting and uneven surfaces further increase the risk of slips, trips, and falls, resulting in injuries.

Temperature Extremes: Confined spaces can experience extreme temperatures, including heat stress in enclosed areas with poor ventilation or cold stress in spaces with low temperatures. Exposure to temperature extremes can lead to heat-related illnesses such as heat exhaustion or heat stroke, as well as hypothermia.

Noise and Vibration: Some confined spaces may expose workers to high levels of noise or vibration, particularly in industrial environments. Prolonged noise exposure can cause hearing loss, while excessive vibration can lead to musculoskeletal disorders such as hand-arm vibration syndrome or whole-body vibration injuries.

Chemical Hazards: Many confined spaces contain hazardous chemicals or substances that pose risks to workers’ health. Exposure to these chemicals through inhalation, ingestion, or skin contact can lead to acute or chronic health effects, including chemical burns, respiratory problems, or systemic toxicity.

Atmospheric Testing and Monitoring

Atmospheric testing is a critical aspect of confined space safety, as it helps identify hazardous conditions that could pose a threat to workers’ health and safety. Using gas detectors and monitoring equipment, workers can assess the atmosphere inside confined spaces for factors such as low oxygen levels, toxic gases, or explosive atmospheres.

Conducting atmospheric tests before entry and periodically during work operations ensures that workers are aware of any changes in air quality and can take appropriate precautions to mitigate risks.

Ventilation Techniques

Proper ventilation is essential for maintaining a safe atmosphere within confined spaces. Various ventilation techniques, such as natural ventilation, forced-air ventilation, and mechanical ventilation systems, help remove contaminants and replenish oxygen levels. Natural ventilation relies on openings such as windows or vents to allow fresh air to enter the space, while forced-air ventilation uses fans to circulate air. Mechanical ventilation systems, such as blowers or exhaust fans, are designed to actively remove contaminants from the confined space.

Lockout/Tagout Procedures

Lockout/tagout procedures are vital for preventing unauthorized access to confined spaces and ensuring the safe isolation of hazardous energy sources. Before entering a confined space, workers must follow specific lockout/tagout procedures to de-energize equipment and machinery and secure them against accidental activation. Proper training and communication are essential to ensure that all workers understand and adhere to lockout/tagout procedures to prevent accidents and injuries.

Training and Certification

Effective training is crucial for equipping workers with the knowledge and skills necessary to work safely in confined spaces. Metro Safety Training offers comprehensive training programs, including occupational first aid level 2 courses in Surrey and confined space safety training courses in Surrey, to provide workers with the necessary tools to identify hazards, implement safety measures, and respond to emergencies. Certification programs ensure that workers meet industry standards and regulatory requirements for confined space safety.

Hands-On Skills Development

Hands-on skills development is an integral part of confined space safety training, allowing workers to practice essential techniques and procedures in a controlled environment. Metro Safety Training offers practical training exercises, such as simulated confined space rescues and equipment usage drills, to enhance workers’ proficiency and confidence. Workers can better prepare for the challenges they may encounter while working in confined spaces.

Case Studies and Success Stories

Real-life case studies and success stories illustrate the importance of mastering confined space safety techniques and the positive impact they can have on workplace safety. By highlighting successful outcomes and lessons learned from past incidents, workers gain valuable insights into the importance of proper training and implementation of safety protocols. These stories serve as powerful reminders of the critical role that confined space safety plays in protecting workers’ lives and preventing accidents in various workplace environments.

Emergency Response Planning

Developing a comprehensive emergency response plan is essential for effectively managing emergencies in confined spaces. The plan should outline procedures for responding to various types of emergencies, including medical emergencies, hazardous substance releases, and equipment malfunctions.

- One of the most critical components of an emergency response plan is procedures for rescue and evacuation. Workers should be trained on how to safely evacuate a confined space in the event of an emergency and how to assist others who may need help. Rescue equipment, such as harnesses, ropes, and stretchers, should be readily available and regularly inspected to ensure it is in good working condition.

- Coordination with external emergency services is essential for ensuring a prompt and effective response to emergencies in confined spaces. Local emergency responders should be familiar with the layout of the facility and the hazards associated with confined space work to facilitate a swift rescue operation if needed.

- Post-incident debriefing and review are critical for identifying lessons learned and implementing corrective actions to prevent future incidents. After any emergency or near-miss event, a thorough review should be conducted to determine what went wrong and how similar incidents can be prevented in the future.

- Regular drills and simulations are essential for testing the effectiveness of the emergency response plan and ensuring that all workers are familiar with their roles and responsibilities in an emergency. By practicing emergency procedures regularly, workers can respond quickly and effectively when faced with a real emergency in a confined space.

Personal Protective Equipment (PPE)

Proper selection and use of personal protective equipment (PPE) are crucial for ensuring the safety of workers in confined spaces. When working in confined spaces, workers may be exposed to various hazards, including toxic gases, airborne contaminants, and physical hazards such as sharp objects or falling debris. To mitigate these risks, it’s essential to provide workers with the appropriate PPE.

- One of the most critical pieces of PPE for confined space work is respiratory protection. Depending on the hazards present, workers may need to wear respirators to protect against inhalation of toxic gases or airborne contaminants. Respirators must be properly fitted to each worker and regularly inspected to ensure they provide adequate protection.

- Protective clothing is another essential component of PPE for confined space work. Workers may need to wear coveralls, chemical-resistant suits, or other specialized clothing to protect their skin from exposure to hazardous substances. Gloves should also be worn to protect the hands from cuts, abrasions, or chemical exposure.

- Eye and face protection are vital for safeguarding workers against potential eye injuries from flying debris or chemical splashes. Safety glasses or goggles should be worn at all times when working in confined spaces, and face shields may be necessary for additional protection against hazards such as arc flash or caustic liquids.

- Before entering a confined space, workers should undergo thorough confined space safety trainingon the proper selection, use, and maintenance of PPE. They should also receive training on how to recognize potential hazards and respond appropriately to emergencies. Regular inspections and maintenance of PPE are essential to ensure it remains in good working condition and provides effective protection against workplace hazards.

Communication Protocols for Confined Space Safety Training in Surrey

Effective communication is paramount for coordinating activities and ensuring the safety of workers in confined spaces. Clear communication protocols must be established to facilitate communication between workers inside the confined space and those outside, as well as between workers and supervisors.

- Before entering a confined space, workers should participate in pre-entry briefings to review the work to be performed, potential hazards, and emergency procedures. During the briefing, workers should also establish a communication plan, including designated signals or codes to indicate the need for assistance or evacuation.

- Continuous monitoring of workers’ status is essential to ensure their safety while working in confined spaces. Workers inside the confined space should maintain regular communication with attendants stationed outside, providing updates on their status and any changes in conditions. Two-way radios or other communication devices should be used to maintain constant contact between workers and supervisors.

- In the event of an emergency, clear communication protocols are critical for coordinating rescue efforts and ensuring the safety of all workers involved. Emergency signals or alarms should be established to alert workers to evacuate the confined space immediately. Regular training drills and simulations can help reinforce communication protocols and ensure workers are prepared to respond effectively to emergencies.

10 Reasons for Confined Space Safety Training

- Legal Compliance: Ensuring your employees undergo confined space safety training guarantees adherence to regulatory standards set by organizations like OSHA, CSA, and WorkSafeBC, mitigating the risk of fines and penalties.

- Worker Safety: Training in confined space safety safeguards employee health and well-being, equipping them to recognize and mitigate hazards such as toxic atmospheres and limited egress, thus reducing the likelihood of accidents.

- Risk Reduction: Investing in training decreases the chances of workplace incidents by empowering employees to identify and address potential hazards effectively, thereby minimizing risks associated with confined space work.

- Emergency Preparedness: Comprehensive fall protection, confined space safety, and first aid traininginclude emergency response protocols, enhancing employees’ ability to respond swiftly and efficiently to emergencies, potentially preventing further harm.

- Increased Efficiency: Well-trained employees operate more efficiently in confined spaces, leading to improved productivity and operational efficiency, ultimately benefiting the organization’s bottom line.

- Cost Savings: Though initial training costs are incurred, they are offset by long-term savings through reduced medical expenses, workers’ compensation claims, and downtime resulting from accidents.

- Enhanced Reputation: Prioritizing employee safety enhances the organization’s reputation as a responsible employer, fostering trust among clients, customers, and stakeholders.

- Comprehensive Training Programs: Metro Safety Training offers tailored confined space safety coursescovering all aspects of safety, including fall protection, first aid, and Occupational First Aid Levels 1, 2, and 3, ensuring employees are fully prepared for any situation.

- Certification and Compliance: Completion of training programs results in certification, demonstrating compliance with regulatory requirements and ensuring employees are qualified to perform confined space duties safely.

- Investment in Employee Well-being:By investing in training, organizations demonstrate their commitment to employee health and safety, fostering a positive work environment and ensuring the well-being of their workforce.

Ready to prioritize safety in confined spaces? Contact Metro Safety Training today to enroll in our comprehensive safety training programs and certification courses. With our expert instructors and hands-on approach to learning, you’ll gain the skills and confidence needed to master confined space safety techniques and protect yourself and your team.