Machine guarding is critical in preventing workplace injuries and ensuring employee safety. Proper machine guarding training not only equips workers with the knowledge to identify and mitigate hazards but also instills a safety culture within the organization.

This comprehensive blog explores the significance of machine guarding, training requirements, and best practices for machine safety.

The Importance of Machine Guarding

Machine guarding is essential for protecting workers from injuries caused by moving parts, flying debris, and other machinery-related hazards. Injuries resulting from inadequate machine guarding can be severe, including amputations, lacerations, and even fatalities. Implementing effective machine-guarding measures can significantly reduce the risk of these incidents.

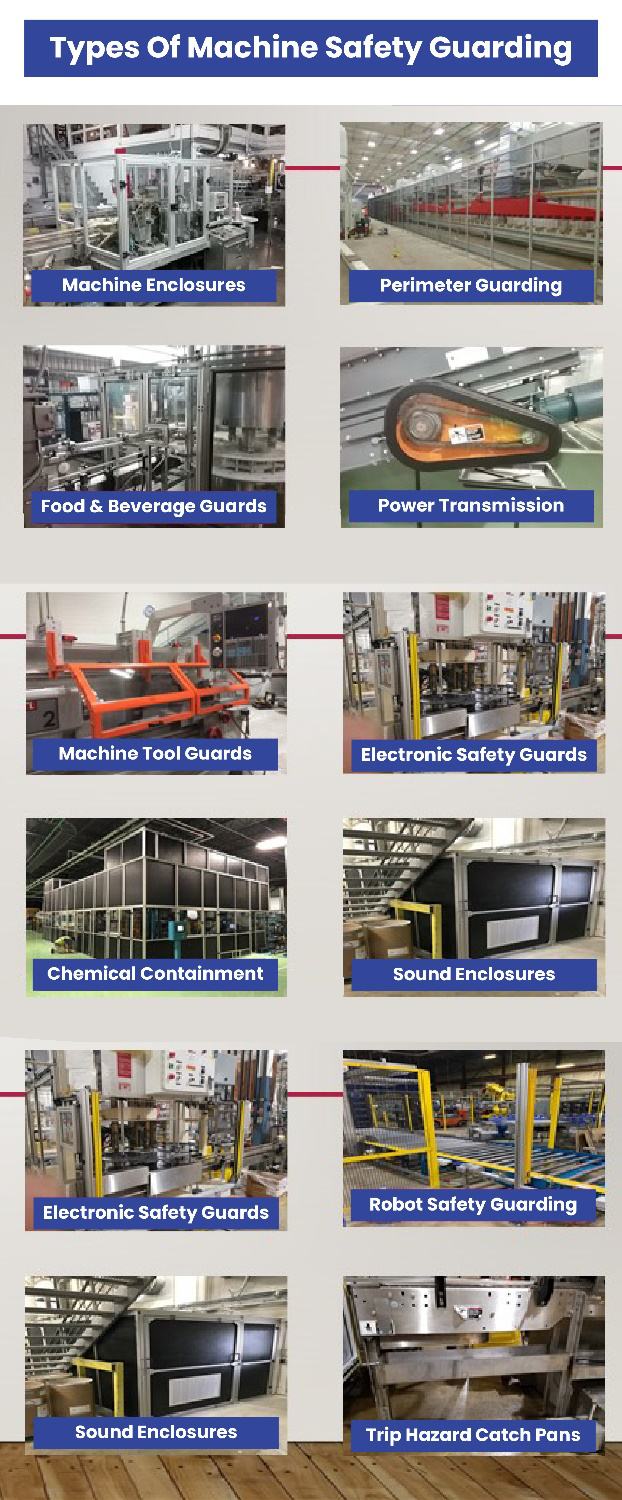

Types of Machine Guarding

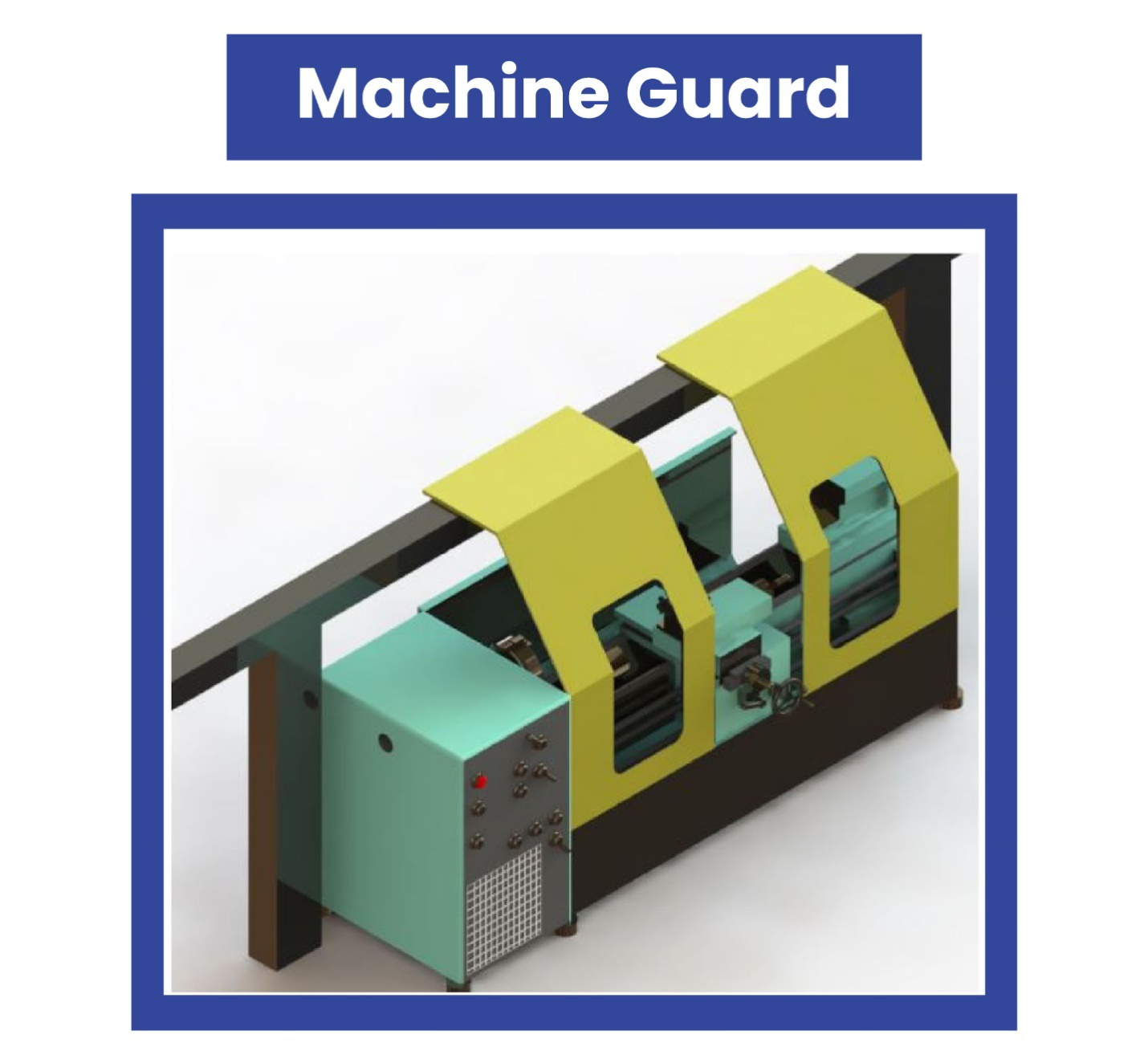

Machine guarding encompasses a variety of methods designed to protect workers, including:

- Fixed Guards: Permanent barriers that protect from machine hazards.

- Interlocked Guards: Safety devices that automatically shut off or disengage machinery when the guard is removed.

- Adjustable Guards: Guards that can be adjusted to accommodate different sizes of materials being processed.

- Self-Adjusting Guards: Guards that move according to the size of the stock entering the danger area.

Understanding the different types of guards and their applications is a fundamental aspect of machine guarding training.

Training Requirements for Machine Guarding

Proper training is crucial for ensuring that workers understand how to operate machinery safely and recognize potential hazards. Comprehensive machine guard and worker safety training should cover the following key areas:

Hazard Identification

Workers must be trained to identify hazards associated with machinery, including pinch points, rotating parts, and points of operation. Training should include:

- Visual Inspections: Conduct regular inspections to identify worn or damaged guards. This involves a thorough examination of all machinery components to ensure they are intact and functioning correctly. Workers should be trained to recognize signs of wear, corrosion, or any other damage that could compromise safety. Plan training like forklift operation safetyand traffic control person courses for employees to maximize worker safety.

- Risk Assessments: Evaluating the potential risks associated with specific machinery and processes. This includes analyzing the machinery’s operating environment, the types of materials being processed, and the interaction of workers with the equipment. Workers should be able to anticipate potential hazards and implement appropriate safety measures.

- Reporting Procedures: Knowing how to report hazards and defective guards promptly. Clear and efficient reporting channels should be established to ensure that any issues are communicated to the relevant personnel without delay. Workers should understand the importance of timely reporting to prevent accidents and maintain a safe working environment.

Additionally, incorporating practical demonstrations and hands-on training can enhance workers’ ability to identify and mitigate hazards effectively. Regular refresher courses and updated training materials are also essential to keep safety knowledge current.

Safe Operating Procedures

Training should emphasize safe operating procedures to minimize the risk of injury. Key topics include:

- Startup and Shutdown Protocols: Understanding the proper procedures for starting and shutting down machinery.

- Safe Work Practices: Following guidelines for safe machine operation, such as keeping hands and clothing away from moving parts.

- Emergency Stop Mechanisms: Knowing how to use emergency stop devices to quickly halt machinery in case of an emergency.

Use of Personal Protective Equipment (PPE)

Proper use of PPE is essential for protecting workers from machine-related injuries. Training should cover:

- Selection of PPE: Choosing the appropriate PPE, such as gloves, safety glasses, and ear protection.

- Correct Usage: Ensuring that workers know how to properly wear and maintain their PPE.

- PPE Limitations: Understanding the limitations of PPE and the importance of using it in conjunction with other safety measures.

Best Practices for Machine Safety

Implementing best practices for machine safety can help create a safer work environment and reduce the risk of injuries. These practices include:

Regular Maintenance and Inspections Regular maintenance and inspections are critical for ensuring that machinery and guards are in proper working condition. Best practices include:

- Scheduled Inspections: Conducting routine inspections of machinery and guards to identify and address any issues. Inspections should be systematic and thorough, covering all aspects of the machinery, including moving parts, electrical components, and safety features.

- Preventive Maintenance: Performing preventive maintenance to keep machinery and guards in optimal condition. This involves regular servicing and replacement of worn parts before they fail, thereby minimizing the risk of unexpected breakdowns and accidents.

- Documentation: Keeping detailed records of inspections and maintenance activities. Documentation should include the date of inspection, findings, actions taken, and the person responsible. These records are essential for tracking the history of the equipment, ensuring compliance with safety regulations, and providing evidence in the event of an incident.

Employee Involvement

Involving employees in safety initiatives can enhance the effectiveness of machine-guarding measures. Best practices include:

- Safety Committees: Establishing safety committees to promote employee involvement in safety programs.

- Feedback Mechanisms: Encouraging workers to provide feedback on machine guarding and other safety measures.

- Recognition Programs: Recognizing and rewarding employees for their contributions to workplace safety.

Continuous Improvement

Continuous improvement is essential for maintaining a safe work environment. Best practices include:

- Ongoing Training: Providing regular training updates to ensure that workers stay informed about the latest safety practices and regulations.

- Safety Audits: Conduct periodic safety audits to identify areas for improvement and implement corrective actions.

- Benchmarking: Comparing safety performance against industry standardsand best practices to identify opportunities for improvement.

Integrating Machine Guarding with Other Safety Training

Machine guarding should be integrated with other safety training programs to create a comprehensive safety culture. Key areas of integration include:

Fall Protection Training

Combining machine guarding with fall protection training can enhance overall workplace safety. Fall protection training should cover:

- Hazard Identification: Identifying potential fall hazards around machinery.

- Protective Measures: Implementing guardrails, safety nets, and personal fall arrest systems.

- Rescue Plans: Developing and practicing rescue plans for fall incidents.

Forklift Operator Training

Integrating machine guarding with forklift operator training can prevent accidents involving powered industrial trucks. Key topics include:

- Safe Operation: Training operators on safe forklift operation near machinery.

- Visibility: Ensuring operators have clear visibility of machine guarding and other safety features.

- Load Handling: Teaching operators to safely handle loads around machinery.

Traffic Control Person Training

Combining machine guarding with traffic control person training can improve safety in areas where machinery and vehicle traffic intersect. Key topics include:

- Traffic Flow Management: Managing traffic flow to prevent collisions with machinery.

- Signaling Procedures: Using proper signaling procedures to communicate with machinery operators.

- Hazard Awareness: Raising awareness of potential hazards associated with machinery and vehicle interactions.

Standard and Emergency First Aid Courses in Surrey

Integrating machine guarding with first aid training can enhance emergency response capabilities. Key topics include:

- Injury Prevention: Emphasizing the role of machine guarding in preventing injuries.

- Emergency Response: Training workers on how to respond to machine-related injuries.

- First Aid Procedures: Providing instruction on first aid procedures for common machine-related injuries.

Confined Space Training in Vancouver

Combining machine guarding with confined space training can improve safety in confined spaces where machinery is present. Key topics include:

- Hazard Identification: Identifying machine-related hazards in confined spaces.

- Entry Procedures: Following safe entry procedures to avoid machine-related injuries.

- Rescue Plans: Developing and practicing rescue plans for confined space incidents involving machinery.

Occupational First Aid Levels 1, 2, and 3

Integrating machine guarding with Occupational First Aid training can enhance overall workplace safety. Key topics include:

- Injury Prevention: Emphasizing the role of machine guarding in preventing injuries.

- First Aid Skills: Providing instruction on first aid procedures for common machine-related injuries.

- Emergency Response: Training workers on how to respond to machine-related injuries.

Occupational First Aid Courses in BC

Offering Occupational First Aid courses in BC that include machine guarding training can improve overall workplace safety. Key topics include:

- Hazard Identification: Identifying machine-related hazards.

- Safe Work Practices: Implementing safe work practices to prevent machine-related injuries.

- First Aid Procedures: Providing instruction on first aid procedures for common machine-related injuries.

Metro Safety Training offers comprehensive machine guarding training programs designed to help organizations improve workplace safety and prevent injuries. Our training programs cover hazard identification, safe operating procedures, and the use of personal protective equipment.

We also offer a wide range of other safety training programs, including fall protection training, forklift operator training, traffic control person training, standard and emergency first aid courses in Surrey,confined space training in Vancouver, and Occupational First Aid Levels 1, 2, and 3 courses.

Contact us today to learn more about our training programs.