Confined spaces, categorized by their restricted access and egress, pose unique challenges and hazards to workers across various industries. These spaces are not intended for continuous occupancy and can range from storage tanks and silos to sewers and tunnels. Despite their compact dimensions, confined spaces demand meticulous attention to safety protocols and comprehensive training due to the potential risks they harbor.

In understanding confined spaces, it’s crucial to recognize that their hazardous nature stems from various factors, including limited ventilation, restricted mobility, and the presence of potentially harmful substances. Workers navigating these environments must be equipped with the knowledge and skills to identify and mitigate these risks effectively.

In this blog, we will delve into the complexities of confined space safety, explore the regulatory bodies governing confined space operations, and discuss the responsibilities of workers in various types of confined spaces.

Regulatory Bodies and Standards

Confined space safety is governed by a comprehensive framework of regulatory bodies and standards, each playing a vital role in ensuring the protection of workers and the enforcement of safety protocols. These regulations are essential for safeguarding individuals who work in confined spaces, where the risk of injury or fatality is heightened due to the unique challenges presented by these environments.

WorkSafe BC in Canada

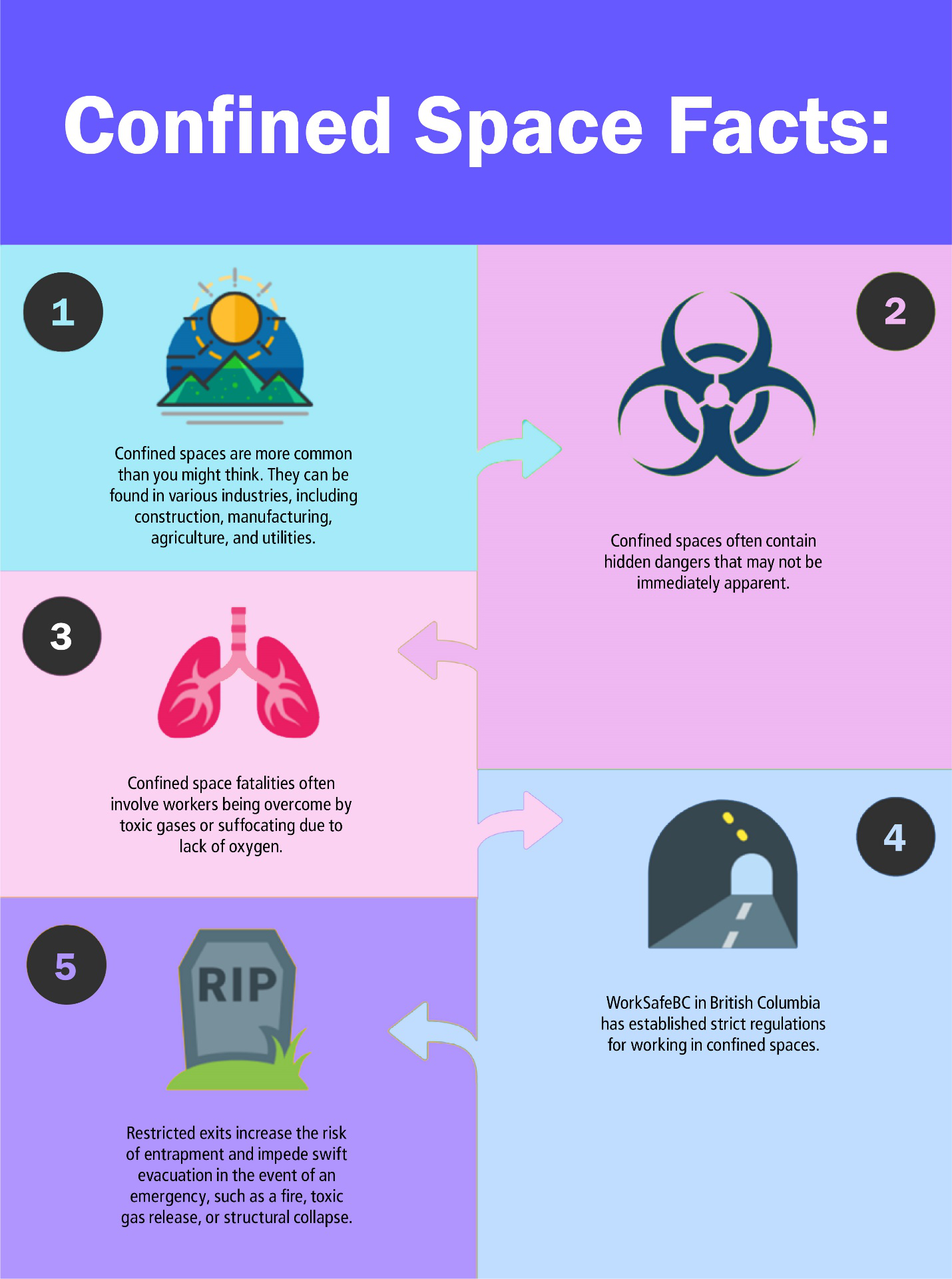

In Canada, confined space safety is regulated by organizations such as the Canadian Standards Association (CSA) and provincial regulatory bodies like WorkSafeBC in British Columbia. CSA develops national standards and guidelines to promote safety and standardization across various industries, including those involving confined spaces.

WorkSafeBC, the provincial regulatory agency responsible for occupational health and safety in British Columbia, enforces regulations specific to confined spaces within the province. These regulations are designed to protect workers from the hazards associated with confined space entry and operation, ensuring that employers take the necessary steps to assess risks, implement controls, and provide adequate training.

Compliance with regulatory requirements is essential for employers to create a safe working environment for their employees. By adhering to OSHA standards in the United States or CSA regulations in Canada, employers demonstrate their commitment to prioritizing worker safety and minimizing the risks associated with confined space work.

The Role of Metro Safety Training in Helping Organisations Adhere to WorkSafeBC’s Regulations

When it comes to ensuring workplace safety, proper training is paramount. In Surrey, Metro Safety Training offers a comprehensive range of occupational first aid and confined space safety training courses to equip workers with the necessary skills and knowledge to navigate hazardous environments effectively.

- Occupational First Aid Level 2 Courses in Surrey:Metro Safety Training provides Occupational First Aid Level 2 courses tailored specifically for Surrey-based workers. These courses cover essential first-aid techniques and protocols to respond effectively to workplace injuries and medical emergencies.

- Fall Protection Courses:Our fall protection courses are designed to educate workers on the importance of fall prevention and mitigation strategies. With hands-on training and practical exercises, participants learn how to identify fall hazards and use appropriate equipment to ensure their safety while working at heights.

- Confined Space Training in Vancouver:For workers in Vancouver, our confined space training courses are essential for understanding the hazards associated with working in confined spaces. From atmospheric testing to emergency response protocols, participants gain the skills needed to navigate confined spaces safely.

- First Aid Training Courses in Surrey:Metro Safety Training offers a variety of first aid training courses in Surrey, including Occupational First Aid Levels 1, 2, and 3. These courses cover a wide range of first aid techniques, from basic wound care to advanced life support, ensuring participants are prepared to handle medical emergencies in the workplace.

- Occupational First Aid Level 3 Pro Renewal:Our Occupational First Aid Level 3 Pro Renewal course is designed for individuals seeking to renew their Level 3 certification. Participants refresh their knowledge of advanced first-aid procedures and learn about the latest developments in occupational first-aid protocols.

By offering specialized training courses tailored to Surrey’s unique needs, Metro Safety Training ensures that workers are equipped with the skills and knowledge necessary to maintain a safe working environment and respond effectively to emergencies.

Hazard Classification System According to WorkSafeBC

In British Columbia, WorkSafeBC provides guidelines and regulations for classifying confined spaces based on the level of hazards present. This classification system helps employers and workers assess risks effectively and implement appropriate safety measures to protect against potential dangers.

- Low-Risk Confined Spaces:Low-risk confined spaces are those areas where the likelihood of encountering hazardous conditions is minimal, and the risks to workers are low. These spaces typically have adequate ventilation, good lighting, and the absence of hazardous materials.

Examples of low-risk confined spaces may include storage closets, electrical vaults with no potential for exposure to harmful substances, or boiler rooms with proper ventilation systems in place. While these spaces may seem relatively safe, workers and employers need to remain vigilant and address any potential hazards promptly.

- Moderate-Risk Confined Spaces:Moderate-risk confined spaces pose moderate risks to workers due to factors such as limited ventilation, the presence of non-life-threatening hazards, or restricted entry and exit points. Examples of moderate-risk confined spaces may include utility vaults, crawl spaces, or trenches with the potential for atmospheric hazards such as reduced oxygen levels or the accumulation of toxic gases.

Workers entering these spaces must follow established safety protocols, including proper ventilation, atmospheric testing, and the use of personal protective equipment (PPE) to mitigate potential risks effectively.

- High-Risk Confined Spaces:High-risk confined spaces present significant risks to workers’ health and safety due to the presence of hazardous conditions such as toxic atmospheres, engulfment hazards, or unstable materials. Examples of high-risk confined spaces include storage tanks, silos, sewers, or chemical processing vessels with known or potential atmospheric hazards, restricted entry and exit points, or the potential for engulfment or entrapment. Workers entering these spaces face imminent dangers that require thorough risk assessment, specialized training, and strict adherence to safety protocols to prevent accidents or injuries.

WorkSafeBC emphasizes the importance of proper hazard identification, risk assessment, and control measures when working in confined spaces. Employers are responsible for implementing safety programs, providing confined space safety training to workers, and ensuring compliance with regulatory requirements to protect against confined space hazards effectively.

Understanding the classification of confined spaces according to WorkSafeBC allows employers and workers to assess the level of risk associated with each space and implement appropriate control measures to ensure safety during entry and work activities. By prioritizing safety and adhering to established guidelines, employers can create a safer working environment for all personnel involved.

Confined Space Hazard Myths and Facts

- Myth: Confined spaces are always small and cramped.

- Fact:While some confined spaces are indeed small and confined, others can be large, such as storage tanks, silos, or underground vaults. The defining characteristic of a confined space is limited access and egress, rather than size.

- Myth: Confined spaces are only hazardous if they contain toxic gases.

- Fact:While toxic gases are a common hazard in confined spaces, other dangers, such as engulfment, entrapment, or oxygen deficiency, can also pose significant risks to workers’ safety.

- Myth: Workers can enter confined spaces without proper training if they’re careful.

- Fact:Confined space entry requires specialized training to identify hazards, use appropriate equipment, and respond to emergencies. Even cautious workers can be at risk without proper training and preparation.

- Myth: Ventilating a confined space eliminates all hazards.

- Fact:While ventilation can reduce certain hazards, such as airborne contaminants, it may not eliminate all risks, especially those related to physical hazards like engulfment or atmospheric conditions like oxygen deficiency.

- Myth: It’s safe to work alone in a confined space if the entry is brief.

- Fact:Working alone in a confined space increases the risk of accidents and reduces the chances of timely rescue in case of emergency. It’s essential to have a competent attendant present outside the confined space to monitor conditions and provide assistance if needed.

Ready to prioritize safety in your workplace? Join Metro Safety Training today and equip yourself with the essential skills and knowledge to ensure a safe working environment. Visit our website to explore our wide range of safety training courses and take the first step towards a safer tomorrow.

Contact us now to schedule your training session and invest in the well-being of your team. Together, let’s make safety a top priority.