Many construction and trade jobs involve working in confined spaces. These are enclosed or partially enclosed areas that are large enough for an adult to enter and perform work but have limited means of entry and exit.

While confined spaces may seem like a normal part of the job, they present unique safety challenges that can be life-threatening. WorkSafeBC, the provincial regulator for occupational health and safety in British Columbia, emphasizes the importance of recognizing confined spaces and implementing proper safety measures to protect workers.

In this blog, we’ll explore the various risks and dangers of confined spaces and offer our confined space safety courses as the best way to respond to them.

Understanding the Dangers of Confined Spaces

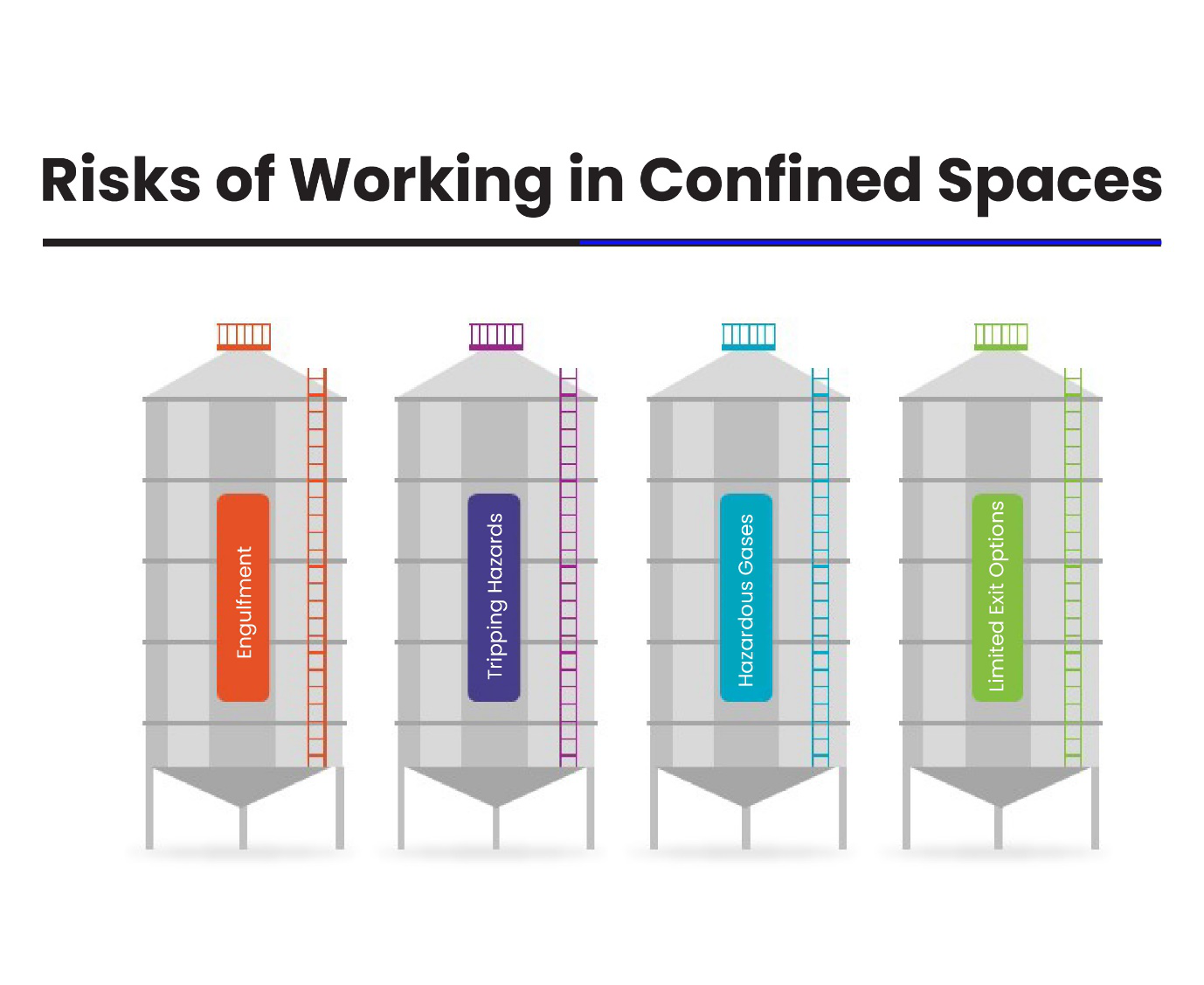

Entering a confined space can expose workers to a variety of hazards, some of which can be invisible or develop over time. Here’s an overview of some of the most common dangers:

- Limited Entry and Exit:Confined spacesoften have narrow openings, making it difficult to enter and exit, especially in an emergency. This restricted access can delay escape and hinder rescue efforts.

- Poor Ventilation:Confined spacesmay lack proper airflow, leading to a buildup of hazardous gases, fumes, or vapors. This can include toxic fumes from chemicals, stagnant sewer gases, or even methane gas from decaying organic matter. Inhalation of these fumes can cause respiratory problems, ranging from mild irritation to serious illnesses.

- Engulfment:Some confined spaces contain materials like water, sludge, or chemicals that can engulf workers, leading to drowning or suffocation. Loss of balance or unconsciousness due to poor air quality can increase the risk of engulfment.

- Physical Hazards:Confined spacescan be cluttered and uneven, with trip hazards from exposed pipes or debris, and sharp objects like rusted metal. Additionally, the presence of moving machinery can increase the risk of entanglement or crushing injuries.

- Temperature Extremes: Finally, confined spacescan experience extreme temperatures, ranging from stifling heat to freezing cold. This can lead to heat exhaustion, hypothermia, or frostbite, and can also exacerbate other health risks associated with confined spaces.

By understanding these dangers and implementing the proper safety protocols, construction and trade professionals can significantly reduce the risks associated with working in confined spaces.

Legal Requirements for Confined Space Entry

Working safely in confined spaces is not just a matter of best practices, it’s a legal requirement in British Columbia. Here’s an overview of the relevant regulations and how they impact employers and workers:

- WorkSafeBC Regulations:The primary governing body for occupational health and safety in BC is WorkSafeBC. Their regulations, specifically Part 9 of the Occupational Health and Safety Regulation (OHSR), outline the legal requirements for confined space These regulations detail employer and worker responsibilities, hazard assessment procedures, and permit requirements.

- Local Bylaws:In addition to WorkSafeBC regulations, some municipalities in British Columbia may have additional bylaws specific to confined space safety. It’s important for employers to be aware of any local regulations that may apply to their workplace.

- Permit-Required Confined Spaces:WorkSafeBC regulations categorize confined spacesbased on the level of risk they present. Permit-required confined spaces are those that pose a high or moderate hazard to workers. These spaces require a written confined space entry permit to be issued by a qualified supervisor before any worker enters. The permit process involves a thorough hazard assessment, development of safe work procedures, and designation of a permit holder responsible for overseeing the confined space

Responsibilities under WorkSafeBC:

- Employers:WorkSafeBC regulations place the primary responsibility for confined space safetyon employers. This includes ensuring all workers receive proper training, conducting hazard assessments, developing safe work procedures, and implementing a permit system for permit-required confined spaces.

- Workers:Workers also have a responsibility to work safely in confined spaces. This includes participating in required training, following safe work procedures, and using appropriate personal protective equipment (PPE). Additionally, workers have the right to refuse to enter a confined space if they believe the work environment is unsafe.

Best Practices for Safe Work Procedures

Navigating confined spaces demands meticulous preparation and adherence to safety protocols. Here are indispensable strategies to ensure the well-being of workers in these challenging environments:

1. Pre-Entry Vigilance and Hazard Identification:

Confined spaces are inherently risky, and entering one unprepared can be a recipe for disaster, which is why pre-entry vigilance is paramount. This involves conducting a meticulous assessment to identify and understand potential hazards before a single worker sets foot inside. Look for warning signs like limited ventilation, stagnant air, or the presence of hissing sounds that might indicate leaking gas lines.

Identify unstable structures, exposed electrical wiring, or the potential for flooding. Think about the materials stored within the space – could they decompose and generate hazardous fumes? By taking the time for a comprehensive pre-entry evaluation, you ensure workers are fully informed about the risks they face and equipped with the necessary knowledge and tools to mitigate those risks effectively.

2. Advanced Training and Qualifications:

Confined spaces are not environments for on-the-job learning. Investing in comprehensive training programs is crucial to equip workers with the knowledge and skills needed to navigate these challenging environments safely. Training should go beyond basic safety protocols. Look for programs that provide specialized instruction specific to confined space entry procedures, emergency response protocols, and effective hazard recognition.

Workers should be able to identify not only the obvious dangers but also the more subtle ones, like oxygen depletion or the presence of flammable materials. Don’t settle for generic training – ensure certification requirements align with industry standards and regulatory mandates set by WorkSafeBC. By prioritizing advanced training and qualifications, you’re guaranteeing competency in high-risk environments, ultimately protecting your workers and ensuring a successful project.

3. Optimal Utilization of Personal Protective Equipment (PPE):

Personal protective equipment, or PPE, is a lifeline for workers in confined spaces. Think of it as a suit of armor, safeguarding them from the various hazards they may encounter. The specific PPE requirements will vary depending on the identified hazards within the confined space. For instance, workers dealing with toxic fumes might require respirators, while those at risk of falls would need harnesses and fall arrest systems.

Don’t skimp on quality – provide workers with appropriate, well-maintained PPE that is specifically designed for the task at hand. Regular inspection and maintenance of this equipment is essential. A faulty respirator or a damaged safety line could render the PPE useless at a critical moment. Proper utilization of PPE is just as important. Workers need to be trained on how to wear and use their equipment correctly to ensure it provides the maximum level of protection.

4. Effective Communication and Emergency Response Protocols:

Confined spaces can be isolating environments, so clear communication is critical for maintaining situational awareness and coordinating activities seamlessly. This means establishing reliable methods for workers to stay connected, like two-way radios for clear voice communication. However, situations may arise where verbal communication is difficult due to noise or limited visibility. In such instances, we advise developing a comprehensive set of hand signals to ensure workers can convey critical information even in challenging conditions.

Another vital aspect is designating a safety monitor to be stationed outside the confined space. This individual acts as a communication hub, relaying information between workers inside and the outside world. They should be trained on confined space rescue procedures and equipped to initiate emergency response protocols if necessary. Don’t let these protocols gather dust on a shelf – regular drills and simulations are essential for reinforcing these procedures and ensuring a swift and efficient response in the event of an emergency.

5. Tailored Work Practices for Construction and Trades:

Construction and trade environments often involve unique confined spaces, presenting challenges that go beyond the standard hazards. A “one-size-fits-all” approach simply won’t cut it. Specialized work practices and procedures tailored to the specific hazards encountered in these industries are essential. For instance, plumbers crawling under buildings will have different safety needs than electricians working in attics.

Task-specific safety protocols should be developed and implemented to address these varying risks. This might involve emphasizing proper handling and securing of tools to prevent them from becoming trip hazards in cramped spaces. It could also mean establishing clear procedures for bringing the right equipment into the confined space and ensuring it is used correctly. By adhering to established procedures and focusing on safe work practices, construction and trade professionals can minimize risks and significantly enhance overall safety performance within confined spaces.

6. Continuous Monitoring and Atmospheric Testing:

Confined spaces can also harbor hidden dangers, and atmospheric conditions can change rapidly, which is why our experts stress regular monitoringprocedures to detect potential hazards before they become a threat. This means implementing a comprehensive monitoring program using calibrated equipment capable of measuring oxygen levels, the presence of toxic gases, and other potential threats. Just like any important skill, workers need training to interpret monitoring results accurately. Understanding the data allows them to identify when conditions become unsafe and take appropriate action.

Atmospheric testing should not be a one-time event. Conduct testing before workers enter the confined space to establish a baseline and periodically during work activities to ensure a safe working environment is maintained throughout the project. By proactively monitoring atmospheric conditions and taking action based on the results, you can significantly reduce the risk of accidents and illnesses associated with confined spaces.

Connect With Metro Safety For Confined Space Safety Training!

Whether you’re a construction firm based in Coquitlam or nearby areas, or are a worker employed within a heavy-duty industry across British Columbia, our experts at Metro Safety Training are here to ensure your teams and confined space worksites remain hazard-free.

Bringing decades of expertise to first aid training and worker safety, our experienced staff is offering a curated selection of safety courses that include training on fall protection, occupational first aid courses, and lots more!

You can also explore our resources on our website or get in touch with your questions directly by leaving them on the contact page. We look forward to hearing from you!