Chemical safety is crucial in workplaces where hazardous materials are handled. Ensuring that employees are trained to manage these risks is vital for maintaining a safe and compliant work environment.

This detailed guide will cover the importance of chemical safety training, effective hazard identification, safe handling procedures, emergency response protocols, and how comprehensive training can help mitigate risks. We will also discuss how integrating chemical safety with other safety training programs enhances overall workplace safety.

The Importance of Chemical Safety Training

Chemical safety training is an essential component of workplace safety programs, particularly in industries where hazardous materials are present. This training is crucial for preventing accidents, minimizing health risks, and ensuring compliance with regulatory standards.

Why Chemical Safety Training Matters

- Regulatory Compliance: In Canada, workplaces handling chemicals must adhere to regulations such as the Workplace Hazardous Materials Information System (WHMIS)and other provincial guidelines. WHMIS ensures that employees are informed about the chemicals they work with through labels, Safety Data Sheets (SDS), and worker education. Compliance with these regulations helps avoid legal penalties and promotes a safer work environment.

- Health and Safety Protection:Chemical exposure can lead to various health issues, including respiratory problems, skin irritation, and long-term illnesses such as cancer. Effective training helps workers understand the potential risks and adopt practices that protect their health. This training complements other safety programs like fall protection training and confined space safety training, ensuring a comprehensive approach to worker safety.

- Accident Prevention: Proper training in chemical safety reduces the likelihood of spills, leaks, and accidental exposures. This includes teaching employees how to handle chemicals safely, use personal protective equipment (PPE), and implement proper storage and disposal practices. Training in these areas can be integrated with fall protection coursesto address potential risks in different work scenarios.

- Emergency Preparedness:Chemical safety training equips employees with the knowledge to respond effectively in case of a chemical spill or exposure. This includes understanding how to use emergency equipment and follow emergency protocols to minimize harm. Training should be complemented by first aid training courses in Surrey and advanced OFA courses to ensure a well-rounded emergency response capability.

Hazard Identification in Chemical Safety

Effective hazard identification is the foundation of a robust chemical safety program. Identifying and understanding chemical hazards allows organizations to implement appropriate safety measures and protect workers from potential risks.

Identifying Chemical Hazards

- Chemical Properties: Each chemical has unique properties that determine its hazards. These include flammability, reactivity, toxicity, and corrosiveness. Understanding these properties is crucial for safe handling and storage. For example, highly flammable chemicals should be kept away from ignition sources, while reactive chemicals may require special storage conditions.

Training in asbestos, lead, and silica awareness is also important as these substances present additional risks.

- Labeling and Safety Data Sheets (SDS):Proper labeling and SDS provide critical information about chemical hazards, including handling instructions, first aid measures, and emergency procedures. Employees should be trained to read and interpret these documents to ensure they understand the risks and necessary precautions. This training should be integrated with confined space training in Vancouver to address specific hazards in different environments.

- Workplace Surveys: Conducting regular surveys and risk assessments of areas where chemicals are used or stored helps identify potential hazards. This includes evaluating the condition of containers, ventilation systems, and emergency equipment. Regular surveys should be complemented by fall protection training to address potential risks from working at heights or on elevated surfaces.

- Historical Data: Reviewing past incidents and near misses related to chemical handling can provide insights into potential hazards and areas for improvement. This data should be used to refine safety procedures and training programs. Incorporating findings from Occupational First Aid Level 3 Pro Renewal can enhance the response protocols for chemical incidents.

Safe Handling Procedures

Safe handling procedures are essential for preventing chemical spills, exposures, and accidents. Proper practices ensure that chemicals are used and stored in a manner that minimizes risks.

Key Safe Handling Practices

- Personal Protective Equipment (PPE):Using appropriate PPE, such as gloves, goggles, face shields, and respirators, is crucial for protecting workers from chemical exposure. Training should cover the correct selection, use, and maintenance of PPE, including how to don and doff equipment properly. This training should be integrated with fall protection courses to ensure comprehensive protection in various work scenarios.

- Proper Storage:Chemicals should be stored according to their compatibility and in suitable containers to prevent leaks and reactions. This includes using appropriate storage cabinets, maintaining proper ventilation, and following specific storage requirements for different types of chemicals. For example, flammable liquids should be stored in explosion-proof cabinets. Combining confined space safety training with chemical storage procedures helps address additional risks in confined environments.

- Handling Techniques:Employees should be trained in proper handling techniques to avoid spills and accidents. This includes using spill containment kits, handling chemicals carefully, and ensuring proper labeling and segregation of chemicals. Training in Occupational First Aid Levels 1, 2, and 3 can provide additional skills for managing incidents that occur despite following safety protocols.

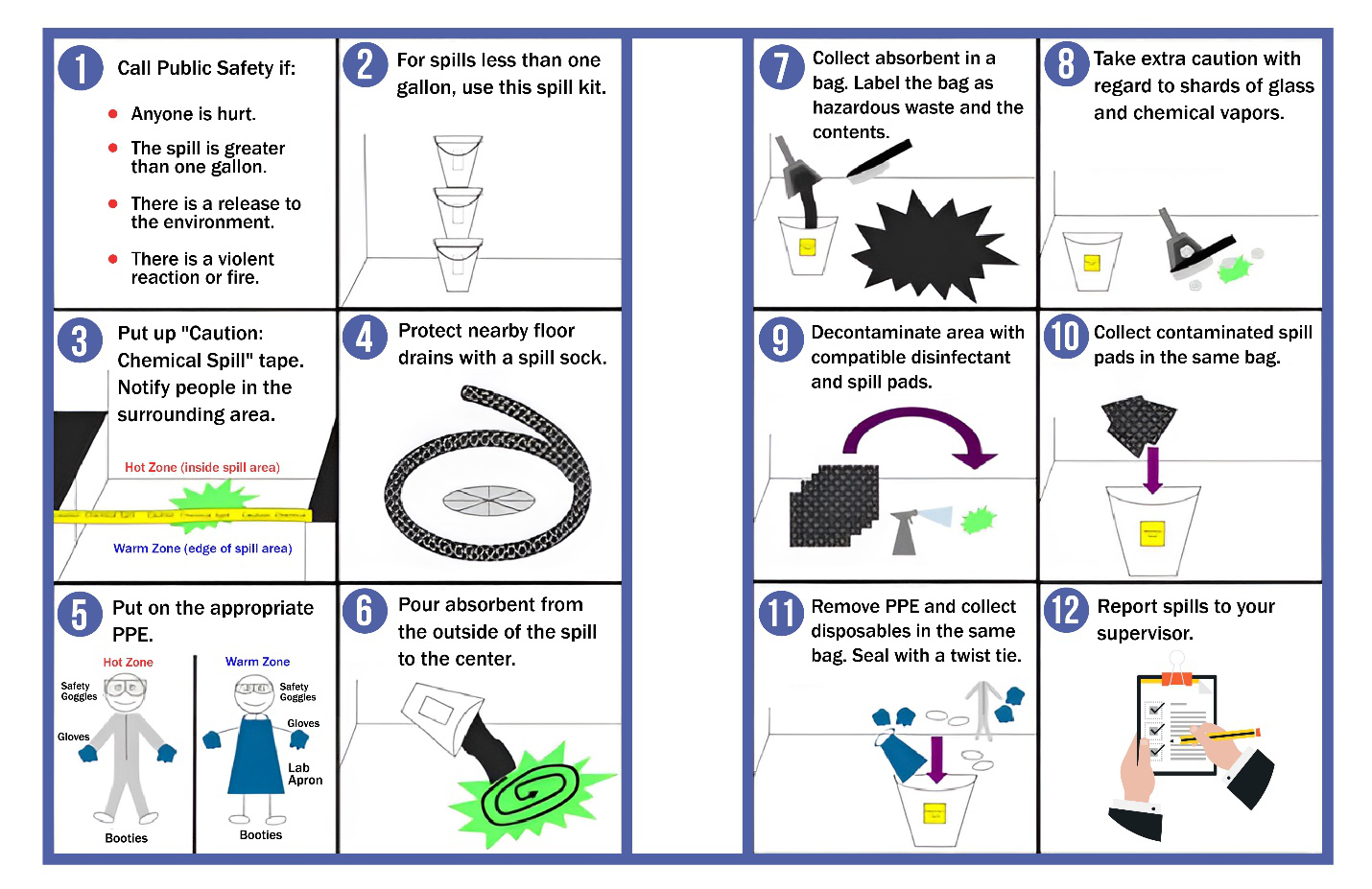

- Spill Management:Implementing procedures for managing spills, including using spill kits and decontamination equipment, is vital. Employees should be trained to respond quickly and effectively to minimize the impact of spills. This training should be supported by first aid training courses in Surrey to ensure comprehensive response capabilities.

Integration with Other Safety Training

Integrating chemical safety training with other safety training programs enhances overall workplace safety and ensures comprehensive protection for employees.

Combining Training Programs

- Fall Protection Training:In environments where chemicals are handled at heights or on elevated surfaces, integrating fall protection training ensures that employees are protected from falls as well as chemical hazards. This includes using harnesses, fall arrest systems, and proper work positioning techniques.

- Confined Space Training:For work conducted in confined spaces where chemicals are present, confined space training in Vancouver ensures that workers are aware of additional risks and safety measures required. This includes understanding confined space entry procedures, using monitoring equipment, and implementing rescue plans.

- First Aid Training:Occupational First Aid Level 1, 2, and 3 training ensures that employees can provide appropriate first aid in the event of a chemical-related incident. This includes training in CPR, wound care, and specific treatments for chemical exposures. Occupational First Aid Level 3 Pro Renewal offers advanced training for those needing additional certification.

- Asbestos, Lead, and Silica Awareness:Handling hazardous materials such as asbestos, lead, and silica requires specific safety measures and training. Awareness and proper procedures are crucial for minimizing health risks and integrating this with overall chemical safety training ensures comprehensive protection.

Best Practices for Implementing Chemical Safety Training

Effective implementation of chemical safety training involves several best practices to ensure that the training is practical and impactful.

Implementing Effective Training

- Regular Training Updates:Chemical safety protocols and regulations may change, so regular updates and refresher courses are necessary to keep employees informed. This includes updating training materials and practices based on new regulations or emerging risks. Integrating updates with fall protection courses and other safety training ensures that employees are prepared for all potential hazards.

- Interactive Training Methods: Utilizing interactive methods such as hands-on exercises, simulations, and case studies can enhance the effectiveness of chemical safety training. This approach helps employees apply theoretical knowledge in practical scenarios, improving their preparedness for real-world situations.

- Assessment and Feedback:Regular assessments and feedback mechanisms help evaluate the effectiveness of training programs and identify areas for improvement. This includes conducting quizzes, and practical evaluations, and soliciting employee feedback to refine training content and delivery.

- Documentation and Record-Keeping:Maintaining records of training completion, certifications, and refresher courses is essential for compliance and tracking employee progress. This documentation should be regularly reviewed to ensure that all employees meet the required training standards.

At Metro Safety Training, we are committed to enhancing workplace safety through comprehensive and practical training solutions. Whether you need chemical safety training to handle hazardous materials safely or fall protection training to prevent falls, our expert instructors are here to provide top-notch education and certification.

Explore our range of courses, including confined space training in Vancouver, Occupational First Aid Level 1, 2, and 3, and Occupational First Aid Level 3 Pro Renewal. Our programs are designed to equip your team with the skills and knowledge needed to ensure a safe working environment.

Don’t wait to make safety a priority in your workplace. Contact Metro Safety Training today to schedule your training sessions and safeguard your employees. Visit our website to get started with the best first aid training courses in Surrey, fall protection courses, and confined space safety training available.

Stay ahead of the risks—invest in your team’s safety with Metro Safety Training.