Construction sites are inherently hazardous. From falls and equipment mishandling risks to chemical exposures, one wrong step can result in a major workplace injury. Among the most insidious threats lurking in these environments are asbestos, lead, and silica.

These substances, though useful in various industrial applications, pose significant health risks when mishandled. Understanding the dangers associated with these materials and the paramount importance of safety training cannot be overstated.

Let’s have a close look into the risks associated with asbestos, lead, and silica exposure and understand the necessity of comprehensive safety training to safeguard workers’ health.

The Hidden Dangers of Asbestos, Lead, and Silica

Let’s go over the dangers of asbestos, lead, and silica exposure:

1. Asbestos

Asbestos, a group of naturally occurring fibrous minerals, was widely used in construction for its fire-resistant and insulating properties. The Canadian Cancer Society reports that asbestos-related cancers are a leading cause of death among Canadian employees.

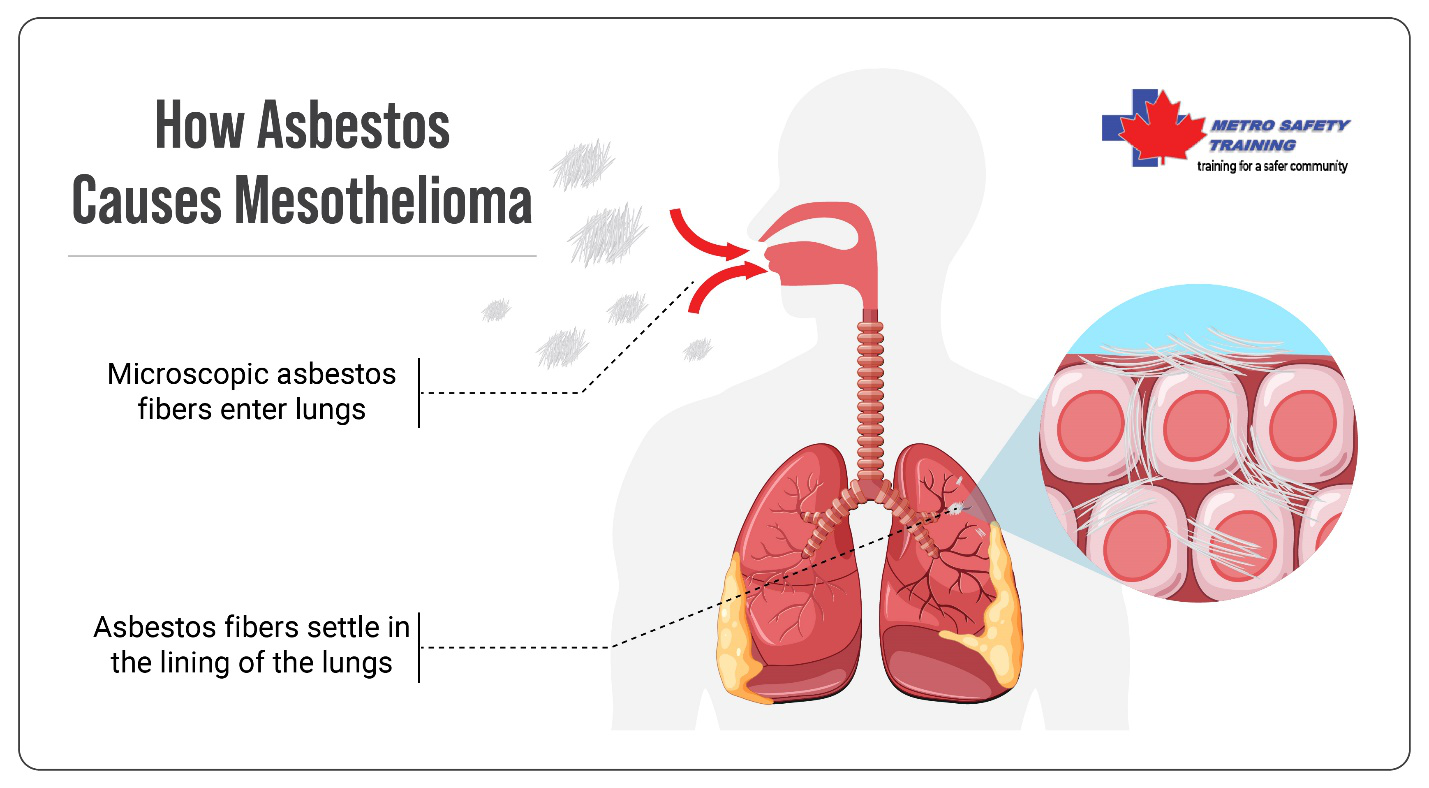

Despite its beneficial attributes, asbestos fibres, when inhaled, can cause severe respiratory issues, including asbestosis, lung cancer, and mesothelioma.

Various studies about asbestos exposure and asbestos-related diseases can take 20-40 years to manifest, often making early detection challenging.

2. Lead

Lead exposure remains a critical concern, especially in older buildings where lead-based paints and pipes are commonly used. According to Carex Canada, 273,000 Canadians are occupationally exposed to lead.

The World Health Organization (WHO) has noted that no level of lead exposure is considered safe, making its presence in construction materials a significant hazard.

Lead is toxic when ingested or inhaled, affecting almost every organ and system in the body. It is particularly harmful to the nervous systems of both adults and children, leading to cognitive impairments and behavioural issues.

3. Silica

Crystalline silica is a common mineral found in materials such as sand, stone, concrete, and mortar.

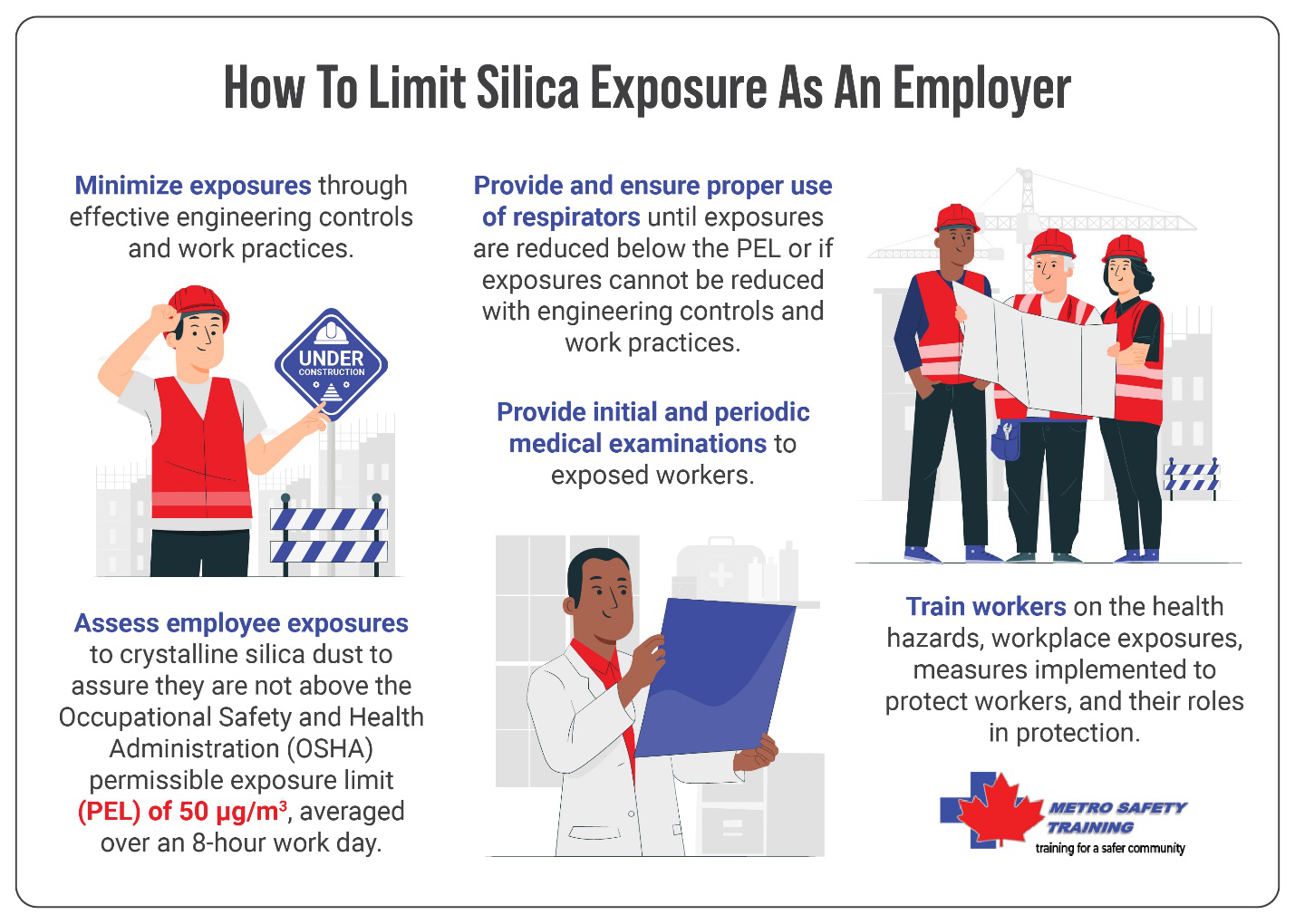

When these materials are cut, ground, or drilled, they release fine silica dust into the air. Prolonged exposure to this dust can lead to silicosis, an incurable lung disease, as well as lung cancer, chronic obstructive pulmonary disease (COPD), and kidney disease.

The Critical Importance of Safety Training

Given the severe health risks associated with asbestos, lead, and silica, employers and workers must engage in thorough safety training programs.

Proper training equips workers with the knowledge and skills needed to identify, manage, and mitigate exposure to these hazardous substances.

Risk Identification and Assessment

A cornerstone of effective safety training is the ability to recognize potential hazards. Workers trained in asbestos, lead, and silica awareness can identify materials that may contain these substances and understand the conditions under which they pose a risk.

This knowledge is critical for preventing accidental exposure and ensuring that appropriate safety measures are implemented.

Safe Handling and Protective Measures

Training programs educate workers on the proper handling techniques for hazardous materials. For asbestos, this includes wetting down materials to prevent fibre release and using specialized equipment for removal.

For lead, workers learn safe removal techniques and how to properly contain and dispose of lead-based materials. Silica safety training focuses on dust control methods such as wet cutting, using vacuum dust collection systems, and wearing appropriate respiratory protection.

Emergency Response and Health Monitoring

In addition to prevention, safety training prepares workers for emergencies. This includes spill response, decontamination procedures, and first aid measures.

Regular health monitoring is also emphasized, ensuring that any signs of exposure-related illnesses are detected early and managed effectively.

Industries Most Prone to Exposure

Certain industries face a higher risk of asbestos, lead, and silica exposure due to the nature of their work. Here are a few industries where workers must be super-vigilant:

1. Construction Industry

The construction industry is perhaps the most widely recognized sector for asbestos, lead, and silica exposure. Within this industry, several specific activities and scenarios present significant risks:

- Demolition and Renovation: Older buildings often contain asbestos in insulation, flooring, and roofing materials. During demolition or renovation, disturbing these materials can release harmful fibres into the air. Lead paint, commonly used in buildings before the 1980s, becomes a hazard when surfaces are scraped, sanded, or otherwise disturbed.

- Concrete Work: Activities such as cutting, drilling, and grinding concrete release fine silica dust. Workers involved in masonry, road building, and construction of concrete structures are particularly at risk.

- Roofing and Insulation: Asbestos was widely used in roofing materials and insulation products. Roofers and insulation installers face significant exposure risks when handling or removing these materials.

- Painting and Sandblasting: Workers engaged in painting, especially in older buildings, are at risk of lead exposure from lead-based paints. Sandblasting activities can also release silica dust from surfaces being cleaned or prepared.

2. Manufacturing Industry

The manufacturing sector involves numerous processes that can lead to exposure to asbestos, lead, and silica:

- Ceramics and Glass Production: The production of ceramics and glass involves materials that contain silica. Workers in these industries are at risk during the handling of raw materials, mixing, and finishing processes.

- Metal Foundries and Smelting: Lead exposure is prevalent in foundries and smelting operations where lead is processed or recycled. Workers can inhale lead fumes during melting or casting processes.

- Chemical Manufacturing: Certain chemical manufacturing processes use asbestos as a filtering agent or in equipment insulation, posing exposure risks to workers.

- Textile Manufacturing: Historically, asbestos was used in the production of fire-resistant textiles. Although less common today, workers in facilities handling old textiles or involved in decommissioning old equipment may still be at risk.

3. Mining Industry

The mining industry is inherently prone to exposure to silica dust and asbestos:

- Silica Dust in Mining: Many mining activities, including drilling, crushing, and transporting ores, generate significant amounts of silica dust. Workers in mines extracting coal, gold, and other minerals frequently encounter this hazard.

- Asbestos in Ore Deposits: Some ore deposits naturally contain asbestos. Miners working in areas with these deposits face exposure risks, particularly when the asbestos fibers become airborne during extraction and processing.

- Lead Mining and Processing: Lead mining and processing operations expose workers to lead dust and fumes, particularly during the extraction, smelting, and refining stages.

4. Shipbuilding and Repair Industry

The shipbuilding and repair industry involves extensive use of asbestos and lead, posing substantial risks to workers:

- Asbestos Insulation: Ships constructed before the 1980s often contain asbestos insulation in engine rooms, boilers, and piping systems. Workers involved in ship repair and maintenance are at risk when removing or working near these materials.

- Lead-Based Paints: Lead-based paints were commonly used on ships for their durability and corrosion resistance. Workers engaged in repainting, stripping old paint, or performing maintenance on painted surfaces are at risk of lead exposure.

Metro Safety Training: Your Partner in Workplace Safety

Given the substantial risks associated with asbestos, lead, and silica, employers must prioritize safety training.

Metro Safety Training offers comprehensive courses tailored to these specific hazards, ensuring that workers are well-prepared to handle these dangerous materials safely.

Asbestos/Lead/Silica Training

Our Asbestos/Lead/Silica Awareness course provides in-depth education on the identification and management of these hazardous substances. The course covers:

- Recognition of asbestos, lead, and silica-containing materials.

- Safe handling and disposal procedures.

- Use of personal protective equipment (PPE).

- Emergency response protocols.

- Health monitoring and reporting requirements.

By completing this course, workers gain the critical skills needed to minimize exposure risks and respond effectively in hazardous situations.

Other Safety and First Aid Training Programs

In addition to asbestos, lead, and silica training, Metro Safety Training offers a variety of other first aid and workplace safety courses in Surrey and the Vancouver area, including:

- Forklift Operator Training: Ensures safe operation of forklifts to prevent accidents.

- Fall Protection Training: Teaches techniques to prevent falls, one of the leading causes of workplace injuries.

- Confined Space Training: Prepares workers for the unique hazards of confined spaces.

- BCCSA Traffic Control Person Training: Trains workers to safely manage traffic around construction sites.

- Occupational First Aid TrainingLevels 1, 2, and 3: Equips workers with the skills to provide immediate medical care in emergencies.

- CPR/AED Level C: Focuses on cardiopulmonary resuscitation and the use of automated external defibrillators.

Invest in comprehensive safety training through Metro Safety Training to ensure your workers are knowledgeable, prepared, and protected against these insidious hazards.

Partner with us and elevate your compliance with laws and regulations, fostering a culture of safety that helps in attracting and retaining top talent. Contact Metro Safety Training to learn more about our first-aid and workplace safety courses in Surrey, Vancouver, and other cities in BC!