The construction industry in Canada presents numerous occupational hazards, especially with exposure to dangerous materials like asbestos, lead, and silica. Managing these risks requires more than basic awareness; it demands advanced strategies that encompass thorough risk assessment, proper use of personal protective equipment (PPE), and ongoing employee education. Construction workers and employers must be proactive, moving beyond asbestos, lead, and silica awareness by implementing comprehensive safety protocols and continuous training.

This blog explores advanced techniques for managing lead and silica risks, alongside asbestos hazards, through better control measures, enhanced training programs, and more effective safety planning. These approaches are vital for ensuring worker safety on Canadian construction sites, especially in compliance with evolving industry standards.

The Health Risks of Asbestos, Lead, and Silica

Asbestos Risks in Construction

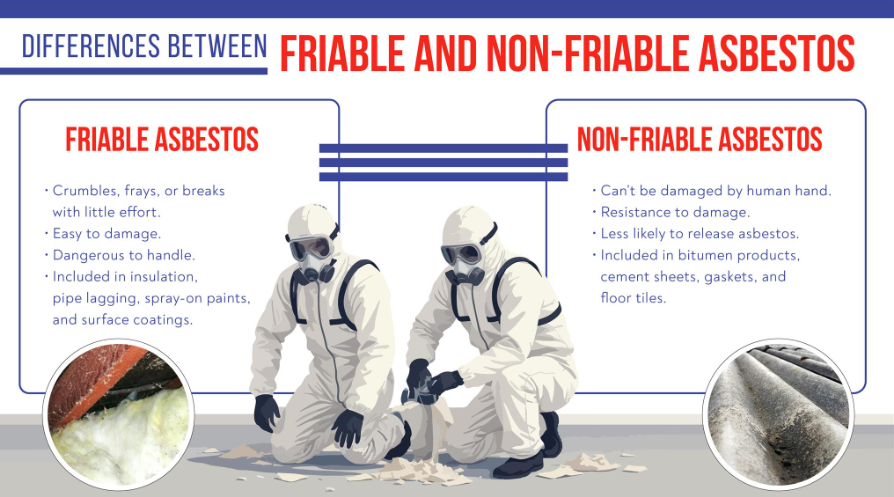

Asbestos, a material historically prized for its fire-resistant properties, was extensively used in building construction until the health hazards became apparent. When asbestos fibers are released into the air due to construction activities such as demolition or renovation, workers can inhale them, leading to severe respiratory diseases such as asbestosis, lung cancer, or mesothelioma. This underscores the importance of asbestos, lead, and silica awareness training for workers handling asbestos-containing materials (ACMs).

While asbestos is highly regulated in Canada, many older buildings still contain ACMs. Simply being aware of the risks is not enough—advanced safety measures and training in first aid training courses are essential to avoid exposure and respond appropriately to any asbestos-related emergencies.

Lead Exposure on Construction Sites

Lead is often found in older building materials, such as pipes, paints, and even soldering materials. Construction activities, such as removing old paint or working in older buildings, can release lead dust or particles into the environment, causing potential exposure through inhalation or ingestion. Lead poisoning is a serious health risk that can affect workers’ nervous systems and even their reproductive health.

To effectively mitigate this, lead and silica awareness courses are crucial. Beyond these, advanced control strategies, including lead-safe work practices and regular health surveillance of workers, must be implemented.

Silica: The Silent Threat

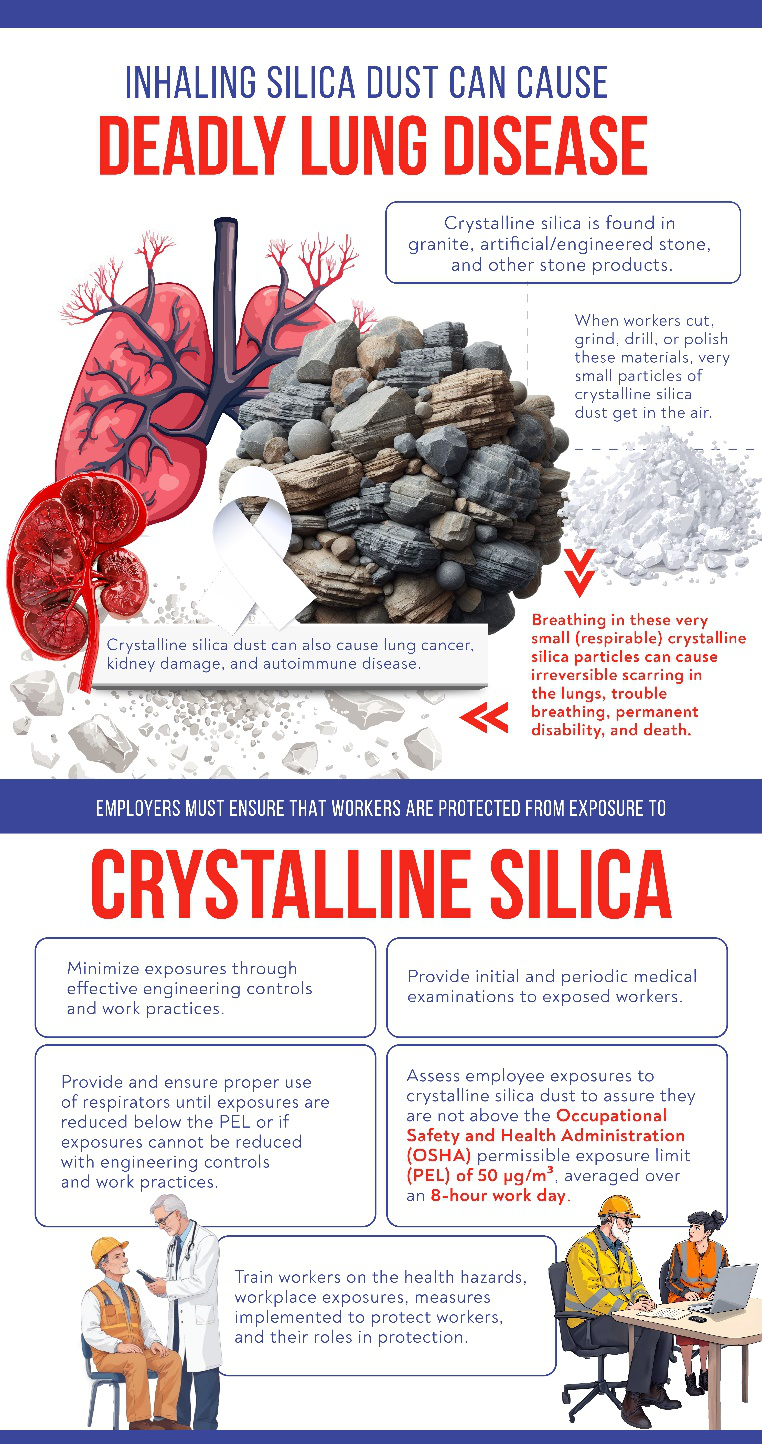

Crystalline silica, often present in materials such as concrete, bricks, and mortar, is released as dust during activities like cutting or grinding. Inhaling respirable silica particles can lead to silicosis, a chronic lung disease, as well as other severe respiratory illnesses. As with asbestos and lead, asbestos, lead, and silica awareness courses are crucial for workers exposed to these materials, but advanced control measures are necessary to limit silica exposure on construction sites.

Advanced Risk Assessment for Hazardous Materials

One of the most effective ways to manage lead and silica risks and asbestos is through detailed, site-specific risk assessments. This goes beyond general safety inspections, as each site and material brings unique hazards. Advanced risk assessments include:

1. Comprehensive Hazard Identification

The first step is identifying potential hazards such as asbestos, lead, and silica in the work environment. This process involves extensive surveys, materials testing, and a deep understanding of the building’s history. In older structures, asbestos-containing materials and lead-based paints are common, while many building materials contain silica.

2. Exposure Monitoring

Exposure monitoring for airborne contaminants is essential in managing lead and silica risks. Using advanced technologies like air sampling devices, employers can track the concentration of hazardous particles in real time. This data allows for timely adjustments in work practices or safety protocols to keep worker exposure within permissible limits.

3. Health Risk Evaluation

Once hazards are identified, conducting an in-depth health risk evaluation is vital. This includes assessing the likelihood of exposure, evaluating control measures, and ensuring workers have received the necessary training, such as occupational advanced first aid courses and Emergency First Aid (EFA) course certifications. Such advanced risk assessments should be performed regularly, particularly in high-risk environments, to safeguard the health of construction workers.

Engineering Controls to Reduce Exposure

Managing asbestos, lead, and silica exposure is best achieved by eliminating or reducing these hazards at their source. Engineering controls are a powerful means to reduce airborne contaminants on construction sites. The following are advanced engineering controls used to minimize exposure:

1. Local Exhaust Ventilation (LEV)

LEV systems capture airborne contaminants at the point of release, preventing them from dispersing into the air. In cases where silica is released during cutting or grinding, or asbestos fibers become airborne, LEV systems act as an immediate control, reducing worker exposure. Using this strategy alongside asbestos, lead, and silica awareness training ensures optimal protection.

2. Wet Methods

Dust generation can be minimized by using wet methods during construction activities. This involves using water to suppress dust while cutting or grinding silica-containing materials. Wet methods can also be used to control asbestos fiber release during abatement activities. Combined with proper basic first aid training, workers can confidently manage these hazards.

3. Enclosures and Isolation Techniques

For asbestos removal or working in areas with high lead and silica risks, isolation techniques like enclosures or barriers are effective. Workers should be trained to safely enter and exit these controlled areas, particularly through confined space training online, ensuring they avoid cross-contamination and manage emergencies effectively.

Personal Protective Equipment (PPE) and Respiratory Protection

While engineering controls reduce exposure, PPE is crucial for further protecting workers from asbestos, lead, and silica. Properly selected and maintained PPE reduces the likelihood of hazardous material exposure and is a vital part of advanced risk management strategies.

1. Respiratory Protection

Respirators, properly fitted and regularly maintained, are critical for workers dealing with asbestos, lead, and silica. Disposable respirators may be suitable for short-term tasks, while more robust equipment like powered air-purifying respirators (PAPRs) should be used for long-term projects. First aid training courses should include respirator fit testing and correct usage techniques.

2. Protective Clothing

In asbestos and lead abatement projects, disposable protective clothing, gloves, and footwear can prevent contamination of workers’ skin and other areas. Workers should be trained on proper donning and doffing procedures to avoid cross-contamination, a key focus in asbestos, lead, and silica awareness courses.

Enhancing Worker Competency Through Advanced Training

While basic first aid training is essential for all workers, advanced training tailored to the specific hazards of asbestos, lead, and silica is necessary to ensure that workers can respond quickly and effectively in hazardous situations. Metro Safety Training offers a range of advanced courses designed to meet the specific needs of Canadian construction workers.

1. Specialized First Aid Training Courses

For those working with hazardous materials, occupational advanced first aid courses offer in-depth instruction on managing injuries and illnesses specific to asbestos, lead, and silica exposure. These courses cover everything from respiratory distress caused by silica inhalation to handling chemical burns from lead-containing materials.

2. Flexible Training Options

For construction professionals working irregular hours, options like intermediate first aid training evening courses Surrey or confined space training online provide the flexibility to stay updated on essential safety practices without disrupting their work schedules. These courses ensure workers remain compliant with Canadian safety standards while being prepared for any situation that may arise.

3. Emergency First Aid (EFA) Course and First Aid Training in Surrey

For those based in the Surrey area, first aid training courses in Surrey offer convenient and location-specific training options. These courses include the Emergency First Aid (EFA) course, which provides essential life-saving techniques specific to the construction environment, ensuring that workers are equipped to handle both common and unique workplace injuries.

At Metro Safety Training, we understand the importance of comprehensive safety protocols in the construction industry, especially when dealing with hazardous materials like asbestos, lead, and silica. Our first aid training courses, including occupational advanced first aid courses, Emergency First Aid (EFA) courses, and confined space training online, are designed to equip workers with the necessary skills and knowledge to handle workplace emergencies confidently.

Contact us now to learn more about our courses and how we can support your company’s safety needs.