Forklifts are a valuable piece of machinery in an industrial and manufacturing zone. They are able to take on heavy items and transport raw materials and products around the business premises effectively.

Like all machinery and equipment used in industrial spaces, there are a lot of health and safety requirements for using forklifts. Here are some essential elements of using a forklift safely:

Train workers keeping their safety in mind

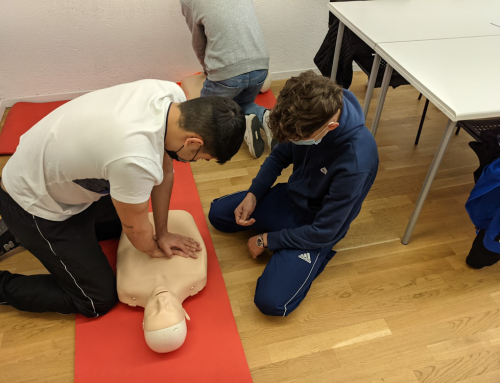

Without adequate safety and training, workers and operators are at a higher risk of injury or death. Forklift safety begins with adequate forklift training. Operators need to be skilled and have enough experience with working forklifts. Training programs to use forklifts effectively include formal instruction, in addition to practical evaluation.

Maintenance procedures

Every piece of equipment requires maintenance for efficient and risk-free use. Maintenance procedures ensure the equipment is working well and any issues and damage are detected early on.

Maintenance procedures for forklifts test out all features of the equipment and service areas that experience wear and tear. Regular maintenance appointments also prevent damage in the long run and can help organizations make the most of their equipment.

The stability triangle is the key to safety

When unloading a forklift, the center of gravity is higher than that of the vehicle. The load it’s carrying has its own center of gravity that balances the vehicle out well. Forklifts are built on the basis of a three-point inspection system, like a triangle.

The support points are at the ends of the front axle while the other is located in the middle of the rear axle. This forms the stability triangle within which the forklift operators must operate.

Taking on excess weight can cause the forklift to move away from its stability triangle, which can put the operator in danger as well as the items being moved.

Fork Inspection

Fork blades must be thoroughly inspected every 6 months to ensure they’re in the best condition possible. These blades tend to develop scratches due to the concrete floor as well as steel shelves. This abrasion wears the forks down, reducing their ability to take on as much weight.

Get in touch with Metro Safety for effective forklift training. Our training courses include understanding all parts of a forklift, its fuel, batteries, evaluation, practical training, and much more. We also provide aid training courses in BC, which includes Standard First Aid, Emergency First Aid, Occupational First Aid, etc. Contact 604-521-4227 for more information about our services.